Adhesion detection method for oxidation film on surface of hot rolling strip steel

A technology of hot-rolled strip steel and surface oxidation, applied in the direction of length measuring device, metal rolling, metal rolling, etc., can solve the problems of complex process, difficult accurate judgment, slow speed, etc. The method is convenient and fast, and the detection result is intuitive , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

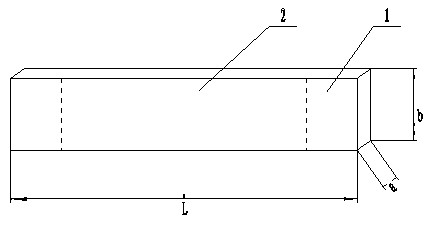

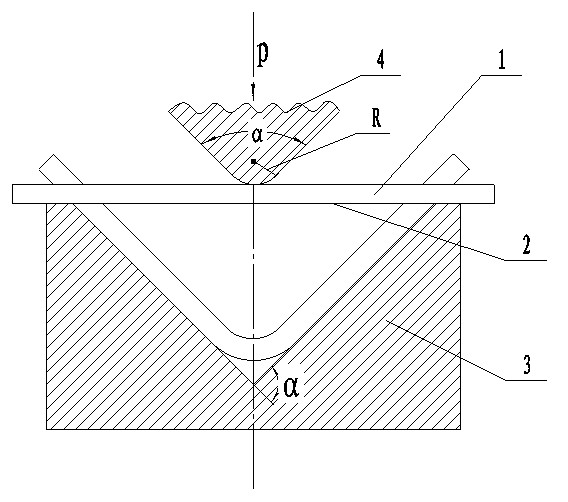

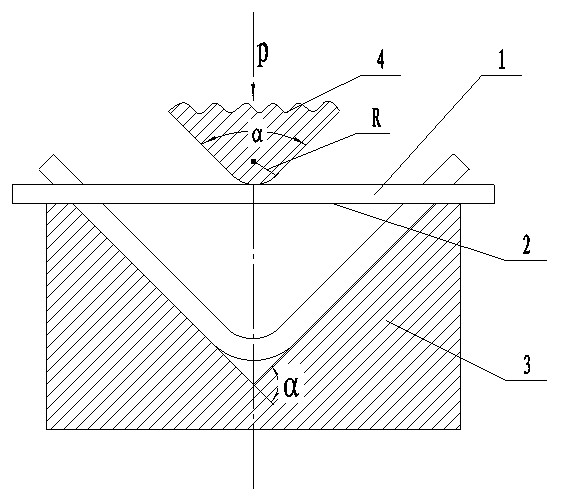

[0014] Such as figure 1 and figure 2 Shown, the embodiment of the present invention is: 1.. cut test piece 1 from hot-rolled steel strip with wire cutting machine, size is L=250mm, b=70mm, and a is the test piece thickness; 2. test piece is with industrial alcohol 1. Scrub the surface clean until there is no dust and oil on the surface; ③. Stick scotch tape 2 on the test surface of test piece 1; ④. Put the test piece 1 with scotch tape 2 on top of the V-shaped mold 3 on the universal testing machine , the surface with scotch tape 2 is on the bottom, apply pressure with a V-shaped indenter with a V-shaped angle α=90°, and a rounded corner of the indenter R=a, and perform a cold bending test with a bending speed of 180mm / min; ⑤. After the experiment, remove the scotch tape from the test piece 1; ⑥. Take pictures of the scotch tape, and then use the software photoshop to convert the photos to obtain the quantitative spectrum of the powder falling condition; 7. Analyze the quant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com