Novel thin strip tractor

A tractor and thin strip technology, applied in the field of tractors, can solve the problems of large fluctuations in traction speed acceleration and deceleration, affecting production efficiency, product quality, and high plate scrap rate, so as to improve product quality, simple structure, and production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

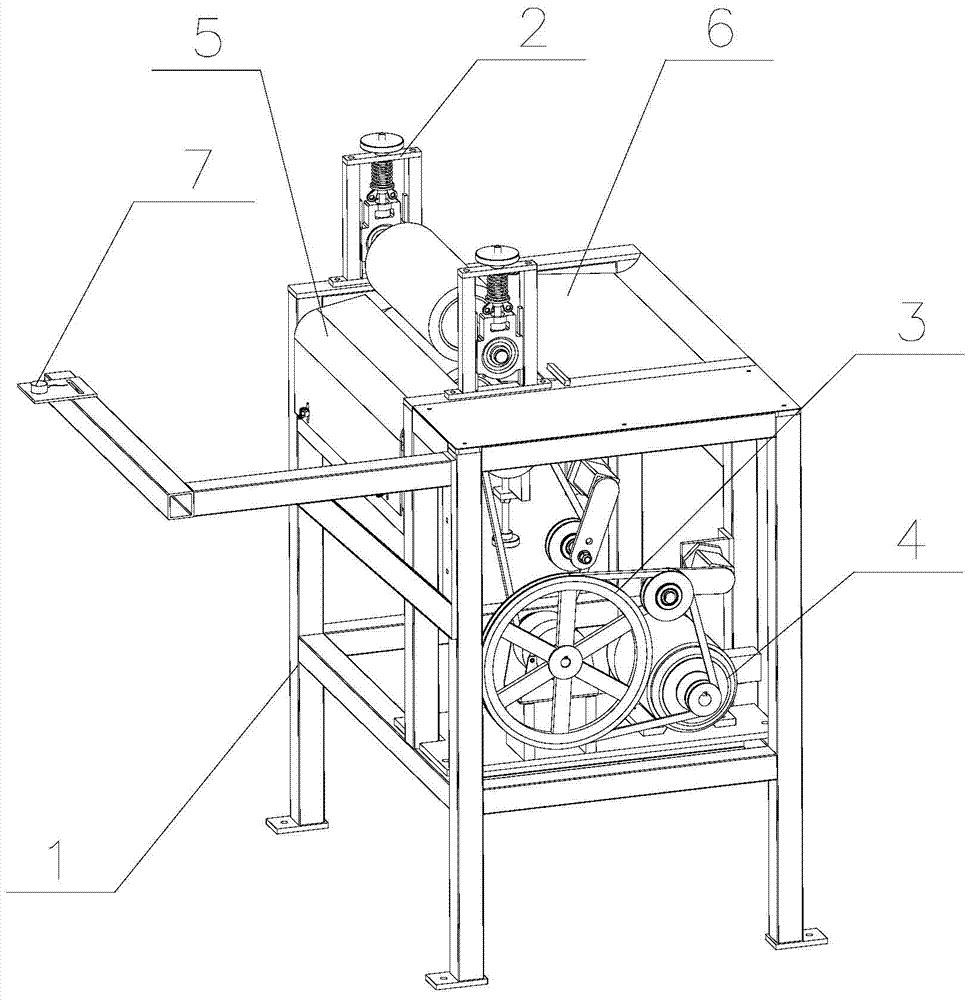

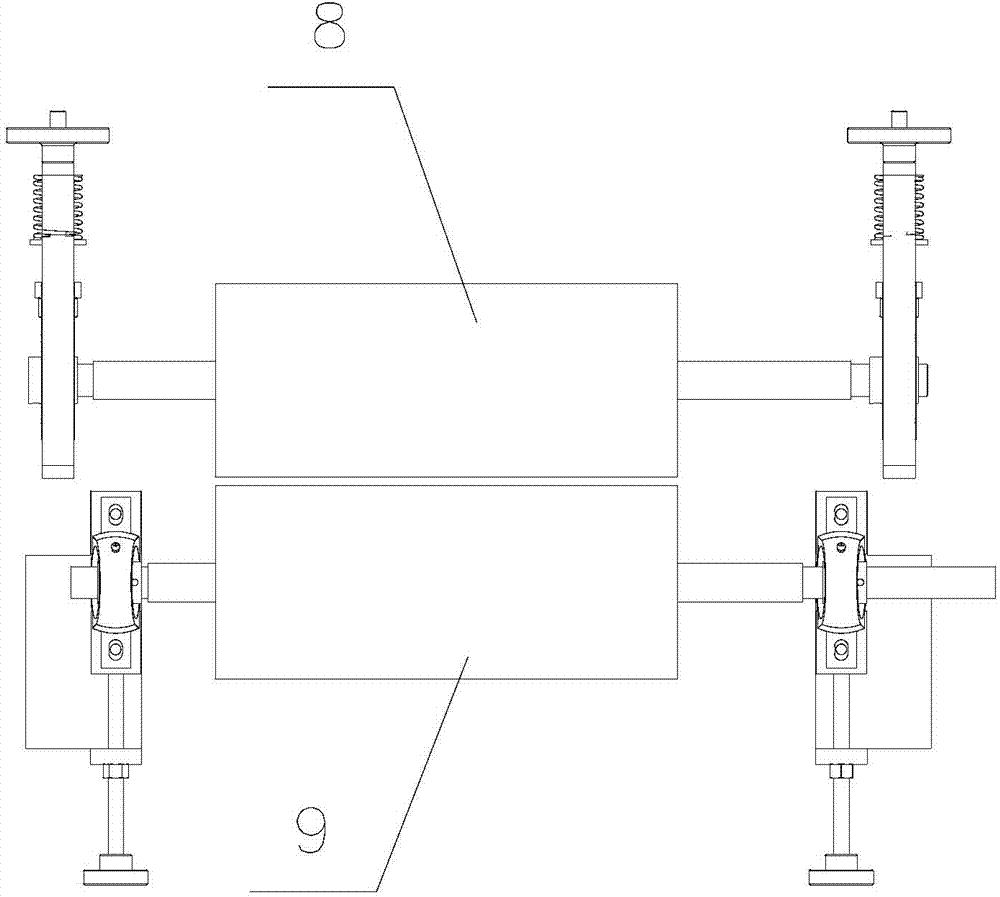

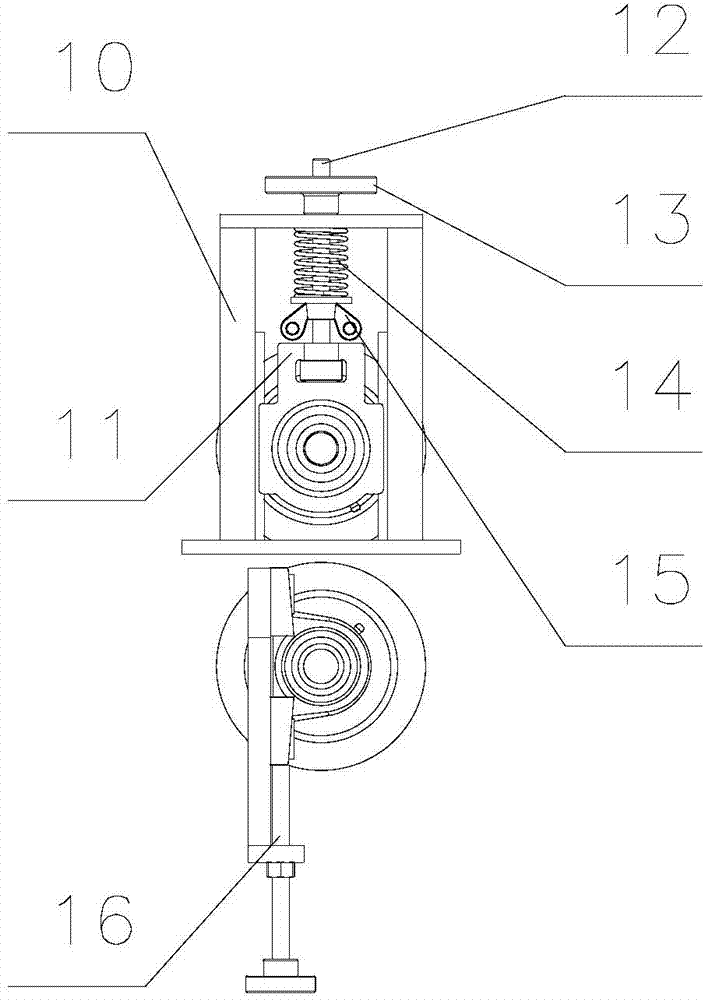

[0019] figure 1 Is a perspective view of the present invention; figure 2 Is a view of the traction device structure; image 3 for figure 2 Left view of Figure 4 Schematic diagram of the structure of the present invention; Figure 5 for Figure 4 The left side view of, as shown in the figure: The new thin belt tractor of this embodiment at least includes a frame 1, a traction device 2, a transmission system 3 and a drive 4. In this embodiment, the traction device 2 is installed on the frame 1. The traction device includes a pair of rollers arranged in parallel up and down, and the lower roller 9 is fixed, and the upper roller 8 is adjustable. The transmission system 3 is provided with a magnetic powder clutch 19. The input end of the magnetic powder clutch 19 is connected with the driver 4. The output end of the clutch is connected to the traction device 2 in transmission.

[0020] In this embodiment, the lower roller 9 of the traction device is installed on the machine frame t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com