Supporting construction method for miscellaneous fill ultra-deep foundation pit through combination of consolidation grouting and double-row steel pipe piles

A technology for steel pipe piles and deep foundation pits, which is used in infrastructure engineering, sheet pile walls, excavation, etc. The effect of avoiding mud pollution, fast and easy sealing and grouting, good anchoring and reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The method of consolidation grouting combined with double-row steel pipe pile support provided in this example includes the following steps:

[0051] (1) Construction of steel pipe piles and grouting retaining structures

[0052] 1. Construction process of steel pipe piles

[0053] Positioning → Drilling machine in place → Drilling → Fabrication and installation of steel pipe piles → Sealing around the steel pipe → Grouting bag sealing pressure grouting.

[0054] 2. The construction process of flower tube grouting

[0055] Positioning → drill in place → drilling → installation of flower tubes → sealing holes around flower tubes → pressure grouting of flower tubes.

[0056] 3. Construction process of crown and beam

[0057] Chiseling pile head → steel bar binding → support formwork → pouring concrete → formwork removal → maintenance.

[0058] 4. Operation points

[0059] 1) Steel pipe material and processing: Steel pipe piles are made of Ф146*5 steel pipes, flower p...

Embodiment 2

[0078] Embodiment 2 application example

[0079] (1) Foundation Pit Support Project of Eastern Hospital of Affiliated Hospital of Qinghai Hospital

[0080] 1.1 Project overview

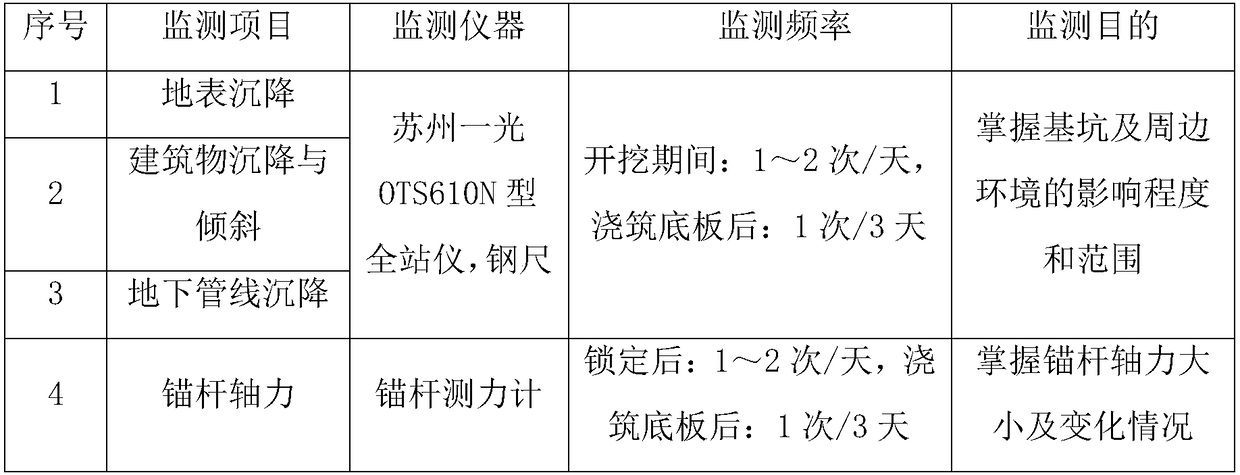

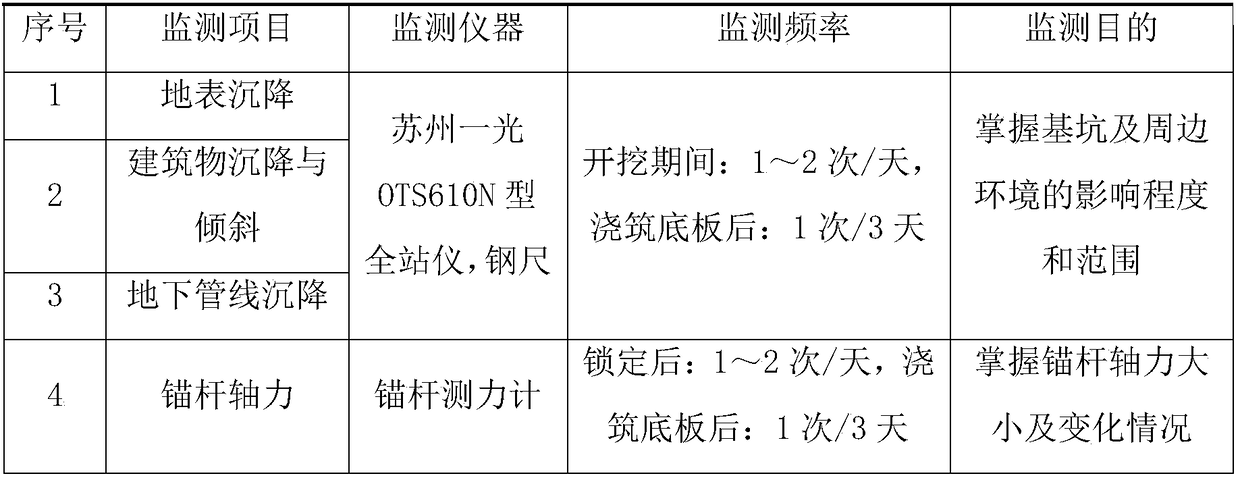

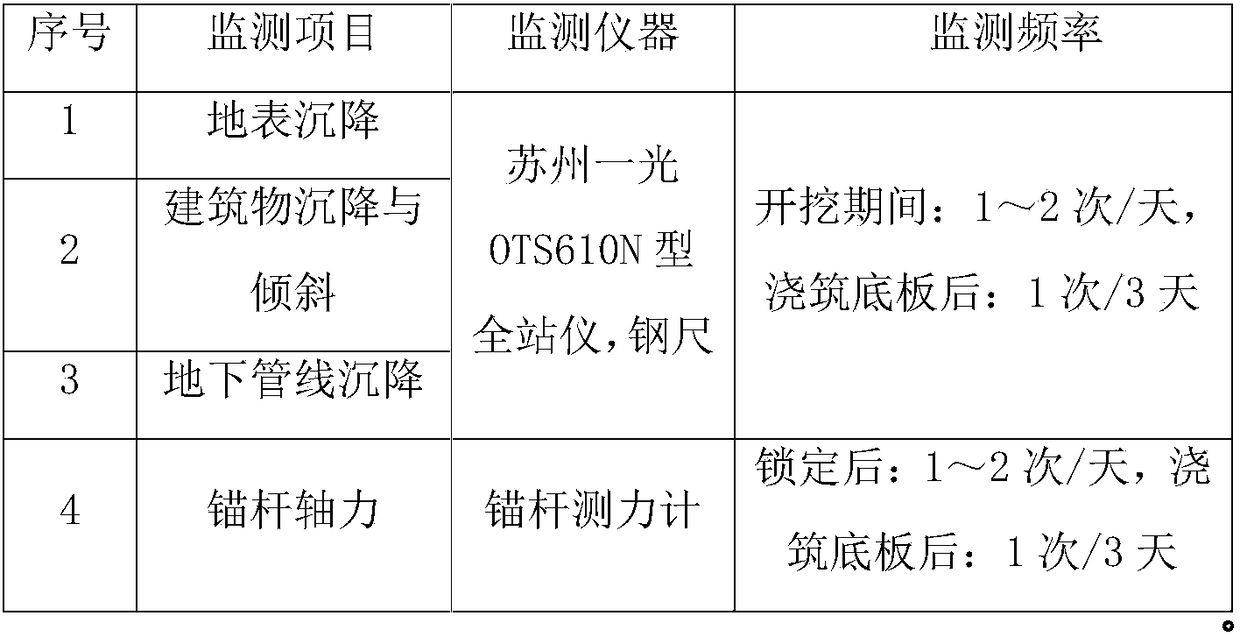

[0081] The project is located in Laoshan District, Qingdao City, with 4 to 16 floors above ground and 3 floors underground, with an absolute base elevation of 12.45 to 15.45m. The total length of the foundation pit is about 590m, and the excavation depth is 10-16m. On the north side of the foundation pit are the existing outpatient and ward buildings. The multi-storey building adjacent to the foundation pit adopts an independent foundation, with the strongly weathered granite zone as the bearing layer, and the excavation line is only 700mm away from the nearest point of the building. The indoor elevation of the building is 31.95m, and the elevation of the independent foundation base is 23.5-25.5m, that is, the thickness of the miscellaneous fill below the indoor flat is 6.45-8.45m, and below the ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com