Preparation method of pure wood pulp natural color paper for daily use

A technology of household paper and natural color, which is applied in papermaking, papermaking machines, textiles and papermaking, etc., can solve the problems of large chemical consumption, high energy consumption, and large environmental pollution, and achieve stable product quality, good quality and performance, and reduce Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

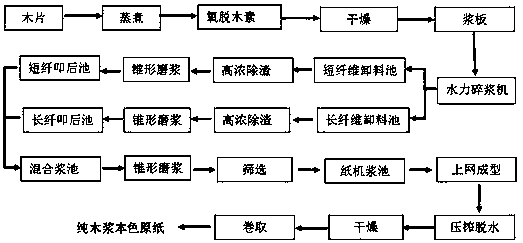

Method used

Image

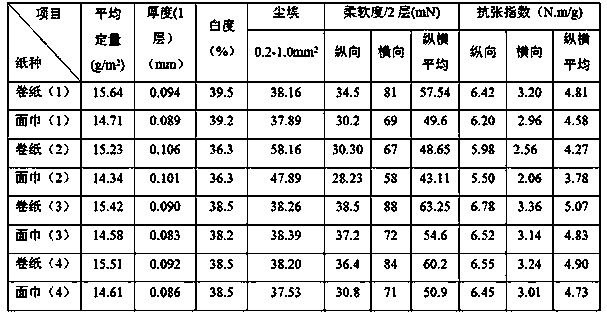

Examples

Embodiment 1

[0028] (1) Slurry preparation

[0029] 1) Preparation of natural color coniferous pulp

[0030] The raw material of natural color coniferous pulp is Simao pine with 14-20 years of age. After peeling, the shaving specifications are controlled according to the length of 15-35mm (the growth direction of wood chips), the thickness ≤ 7mm, and the width ≥ 5mm (horizontal direction of wood chips);

[0031] Sulfuric acid cooking: 28% alkali, 27.4% sulfide, 165°C cooking temperature, 4h cooking time; oxygen delignification: 2.2-2.5% alkali, 18-21kg / admt oxygen, 94 -98°C, time 90min, to obtain natural softwood pulp with a brightness of 28.1%;

[0032] 2) Preparation of natural color hardwood pulp

[0033] The raw material of the natural color hardwood pulp is eucalyptus with a width of 4-6 years. After peeling, the shaving specifications are controlled according to the length 15-35mm (the growth direction of the wood chip fiber), the thickness ≤ 7mm, and the width ≥ 5mm (the horizonta...

Embodiment 2

[0049] Same as Example 1, only the hardwood pulp is replaced by non-wood fiber raw materials.

Embodiment 3

[0051] (1) Slurry preparation

[0052] 1) Preparation of natural color coniferous pulp

[0053] The raw material of natural color coniferous pulp is Simao pine with 14-20 years of age. After peeling, the shaving specifications are controlled according to the length of 15-35mm (the growth direction of wood chips), the thickness ≤ 7mm, and the width ≥ 5mm (horizontal direction of wood chips);

[0054] Sulfuric acid cooking: 25% alkali, 26% sulfide, 170°C cooking temperature, 4h cooking time; oxygen delignification: 2.2-2.5% alkali, 18-21kg / admt oxygen, 90°C -95°C, time 90min, to obtain natural softwood pulp with a brightness of 32%;

[0055] 2) Preparation of natural color hardwood pulp

[0056] The raw material of the natural color hardwood pulp is eucalyptus with a width of 4-6 years. After peeling, the shaving specifications are controlled according to the length 15-35mm (the growth direction of the wood chip fiber), the thickness ≤ 7mm, and the width ≥ 5mm (the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com