Method and device for treating a strip of fibrous material in a long nip press unit

A technology with long nip and pulp width, applied in the press part, textile and papermaking, papermaking, etc., can solve the problems of mechanical pressing and line load limitation, and achieve the effect of good quality performance and good pulp width transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

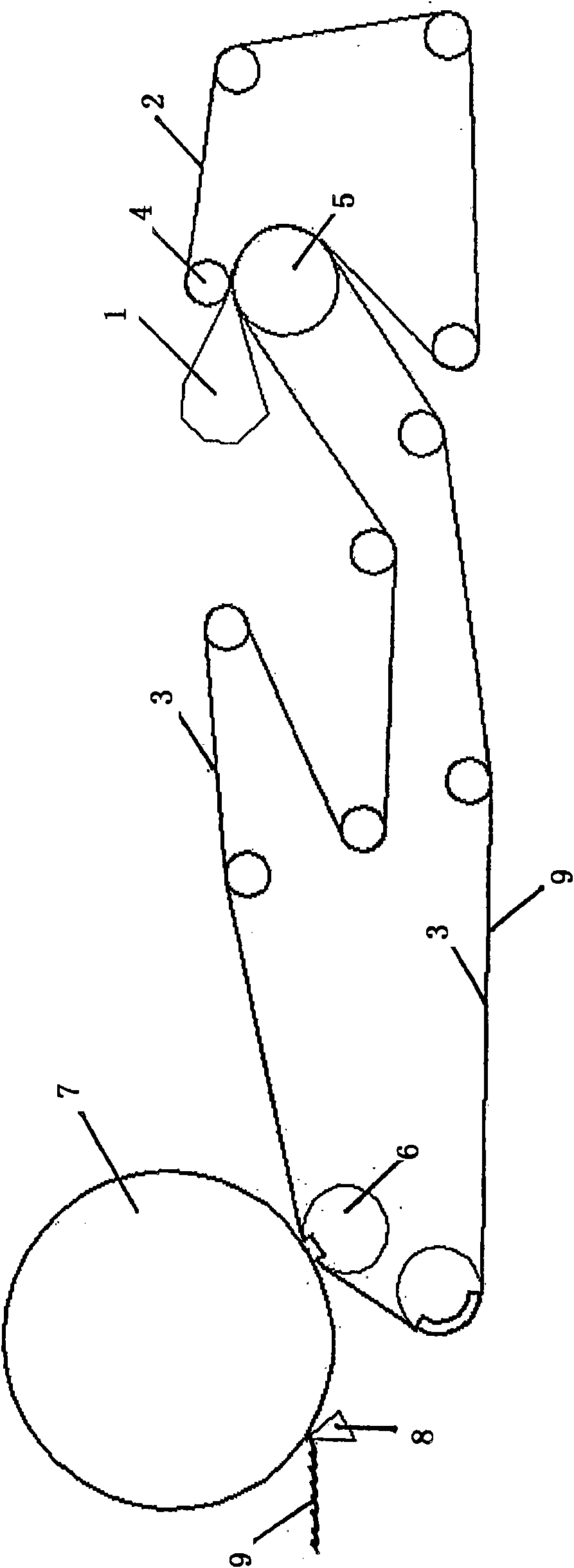

[0033] figure 1 A conventional tissue machine utilizing shoe press technology is shown. The stock suspension is conveyed through the head box 1 to the forming unit and leaves the head box 1 between the breast roll 4 and the forming roll 5 . The outer fabric 2 is wrapped around a breast roll 4 . In the forming unit, the stock suspension is sufficiently dewatered so that a stock web 9 is formed on the fabric 3 . The fabric 3 is preferably a felt, which brings the pulp web 9 to the shoe press roll 6 . An extended press nip is formed between the shoe press roll 5 and the Yankee cylinder 7 , in which nip the pulp web is mechanically dewatered and transferred to the Yankee cylinder 7 . The thermal drying of the pulp web 9 is carried out on the Yankee cylinder 7 . A doctor blade 8 separates a dry pulp web 9 from the Yankee cylinder 7 . Due to the direct pressing of the pulp web 9 onto the Yankee cylinder 7, mechanical dewatering is limited because the shoe press roll 6 cannot be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com