Low-temperature resistant and oil resistant low-smoke halogen-free flame retardant polyolefin cable material and preparation method thereof

A polyolefin cable material, low temperature resistance technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of high swelling rate, low crystallinity, easy hardening and cracking, etc., to improve low temperature resistance performance, improve low temperature resistance, The effect of improving interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

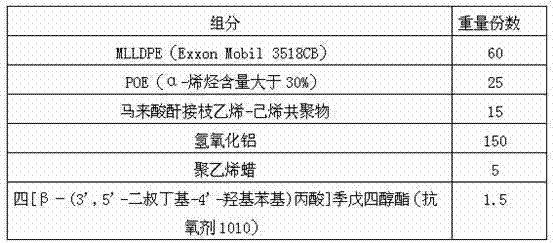

[0016] This example is a low-temperature-resistant, oil-resistant, low-smoke, halogen-free, flame-retardant polyolefin cable material:

[0017] (1) Raw material formula:

[0018] As shown in the following table:

[0019]

[0020] (2) Preparation process:

[0021] First mix the matrix resin, aluminum hydroxide, polyethylene wax and antioxidant fully in a high-speed mixer according to the formula, then extrude through a co-rotating twin-screw extruder at a processing temperature range of 110°C, and then grind the surface Cut into granules by a hot cutting machine, transport and cool by a cyclone separator, and sieve by a vibrating sieve to finally make a low-temperature resistant, oil-resistant, low-smoke, halogen-free, flame-retardant polyolefin cable material.

[0022] (iii) Material properties:

[0023] The properties of the low-temperature, oil-resistant, low-smoke, halogen-free, flame-retardant polyolefin cable material prepared according to the above formula and proc...

Embodiment 2

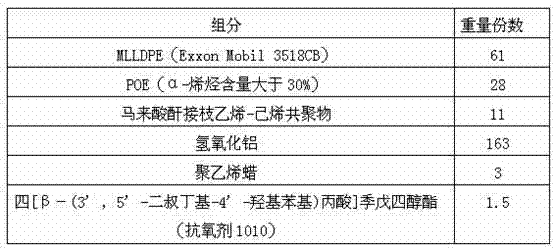

[0025] This example is a low-temperature-resistant, oil-resistant, low-smoke, halogen-free, flame-retardant polyolefin cable material:

[0026] (1) Raw material formula:

[0027] As shown in the following table:

[0028]

[0029] (2) Preparation process:

[0030] Firstly, base resin, aluminum hydroxide, polyethylene wax, and antioxidant are fully mixed in a high-speed mixer according to the formula, and then extruded through a co-rotating twin-screw extruder at a processing temperature range of 160°C, and then ground Cut into granules by a hot cutting machine, transport and cool by a cyclone separator, and sieve by a vibrating sieve to finally make a low-temperature resistant, oil-resistant, low-smoke, halogen-free, flame-retardant polyolefin cable material.

[0031] (iii) Material properties:

[0032] The properties of the low-temperature-resistant, oil-resistant, low-smoke, halogen-free, flame-retardant polyolefin cable material prepared according to the above formula ...

Embodiment 3

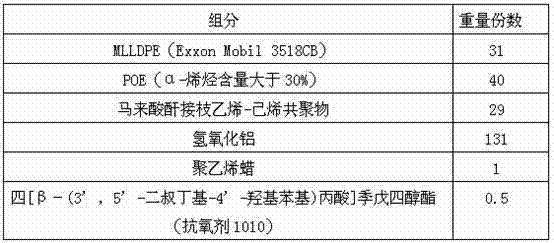

[0034] This example is a low-temperature-resistant, oil-resistant, low-smoke, halogen-free, flame-retardant polyolefin cable material:

[0035] (1) Raw material formula:

[0036] As shown in the following table:

[0037]

[0038] (2) Preparation process:

[0039] First, base resin, aluminum hydroxide, polyethylene wax, and antioxidant are fully mixed in a high-speed mixer according to the formula, and then extruded through a co-rotating twin-screw extruder at a processing temperature range of 120°C, and then ground Cut into granules by a hot cutting machine, transport and cool by a cyclone separator, and sieve by a vibrating sieve to finally make a low-temperature resistant, oil-resistant, low-smoke, halogen-free, flame-retardant polyolefin cable material.

[0040] (iii) Material properties:

[0041] The properties of the low-temperature-resistant, oil-resistant, low-smoke, halogen-free, flame-retardant polyolefin cable material prepared according to the above formula an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com