Annealing process for reducing stress of silicon carbide crystals

An annealing process, silicon carbide technology, applied in crystal growth, chemical instruments and methods, post-processing details, etc., can solve problems such as crystal cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

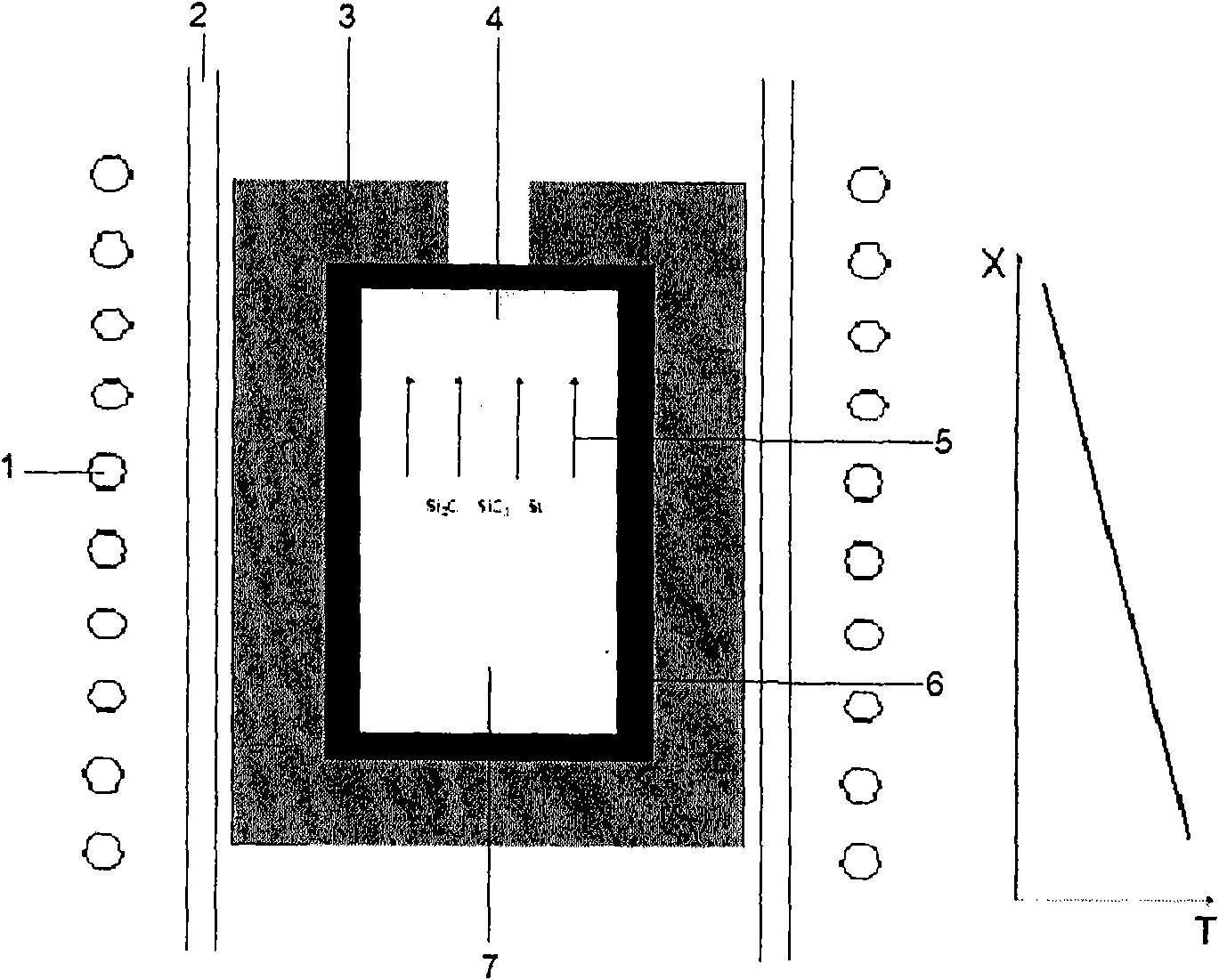

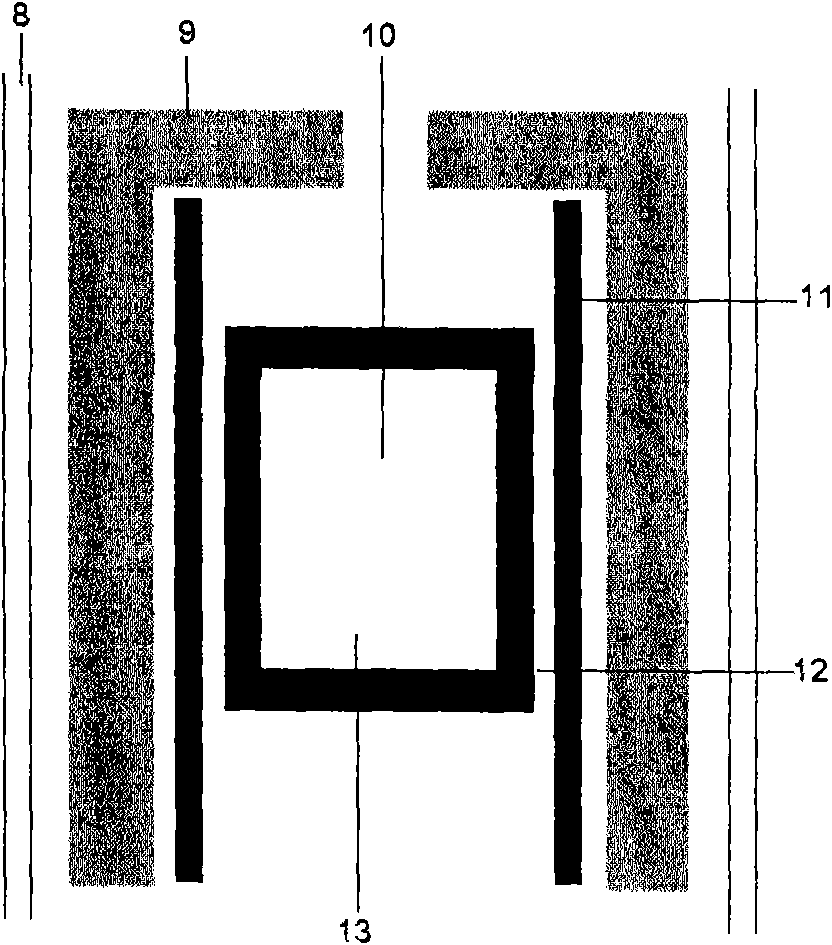

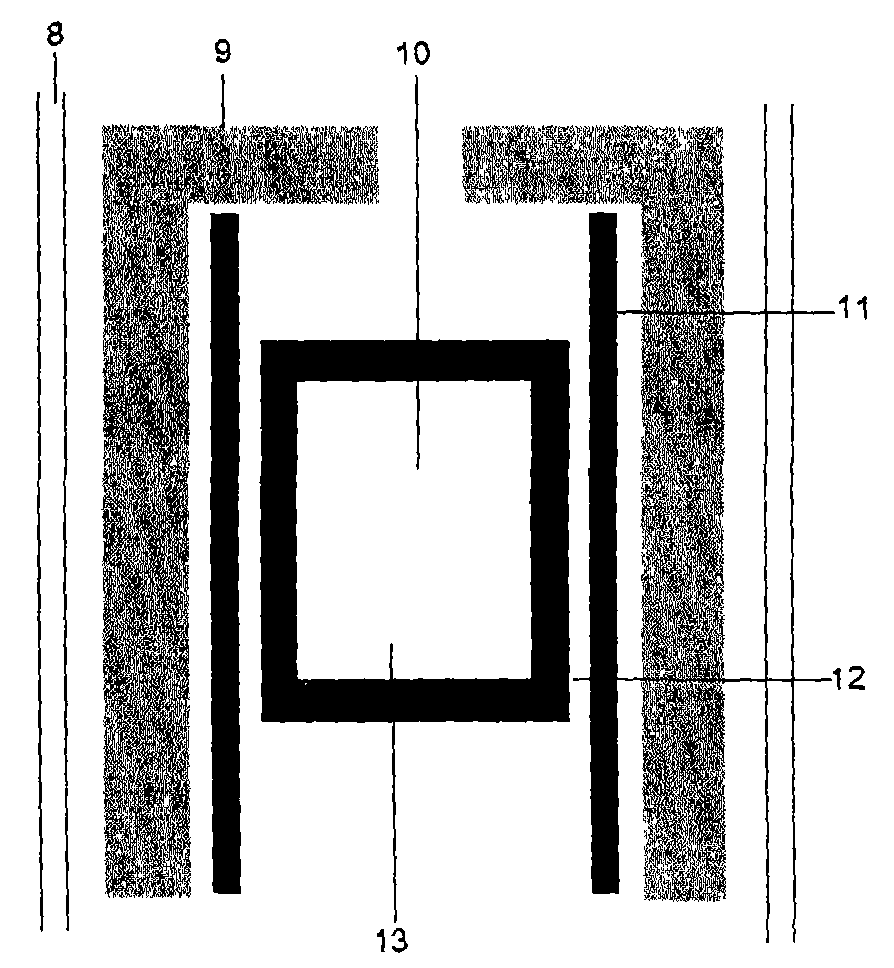

[0030] Put the 2-inch 6H semi-insulating silicon carbide crystal to be annealed directly into the annealing crucible together with the crucible cover, then add an appropriate amount of high-purity silicon carbide raw material around it, and place it in a graphite heating annealing furnace with good sealing performance. The furnace is 12 Hourly air leakage does not exceed 10 Pa. Design the insulation layer outside the crucible so that the temperature gradient is 15-20°C / cm when the crucible is at the annealing temperature. After installing the furnace, evacuate to 5 Pa and then fill with argon to 10,000 Pa. Turn on the power, heat up from 100°C to 2100°C at a speed of 200°C / h for 10 hours, keep the temperature for 10 hours, then cool down from 2100°C to 100°C at a speed of 200°C / h for 10 hours, and then turn off the power directly.

Embodiment 2

[0032] Put the 3-inch 4H conductive silicon carbide crystal to be annealed in the annealing crucible, then add an appropriate amount of conductive silicon carbide raw material around it, and then put it into a well-sealed induction coil heating annealing furnace, which will not leak for 12 hours more than 10 Pa. Design the insulation layer outside the crucible so that the temperature gradient is 10-15°C / cm when the crucible is at the annealing temperature. After installing the furnace, evacuate to 5 Pa and then fill with argon to 20,000 Pa. Turn on the power, raise the temperature from 100°C to 2100°C at a speed of 100°C / h for 20 hours, keep the temperature for 20 hours, then cool down from 2100°C to 100°C at a speed of 100°C / h for 20 hours, and then turn off the power directly.

Embodiment 3

[0034] Put the 4-inch 4H conductive silicon carbide crystal to be annealed in the annealing crucible, then add an appropriate amount of conductive silicon carbide raw materials around it, and then put it into a well-sealed induction coil heating annealing furnace, and the furnace will not leak more than 12 hours. 10 Pa. Design the insulation layer outside the crucible so that the temperature gradient is 5-10°C / cm when the crucible is at the annealing temperature. After installing the furnace, evacuate to 5 Pa and fill with argon to 40,000 Pa. Turn on the power, heat up from 100°C to 2100°C at a speed of 50°C / h for 40 hours, keep the temperature for 30 hours, then cool down from 2100°C to 100°C at a speed of 50°C / h for 40 hours, and then turn off the power directly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com