Method for preparing thermoplastic fiber-hybrid woven composite

A technology of thermoplastic fibers and composite materials, applied in chemical instruments and methods, textiles, fabrics, etc., can solve problems such as the difficulty of reinforcing fibers, and achieve the effects of overcoming impregnation difficulties, good mechanical properties, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

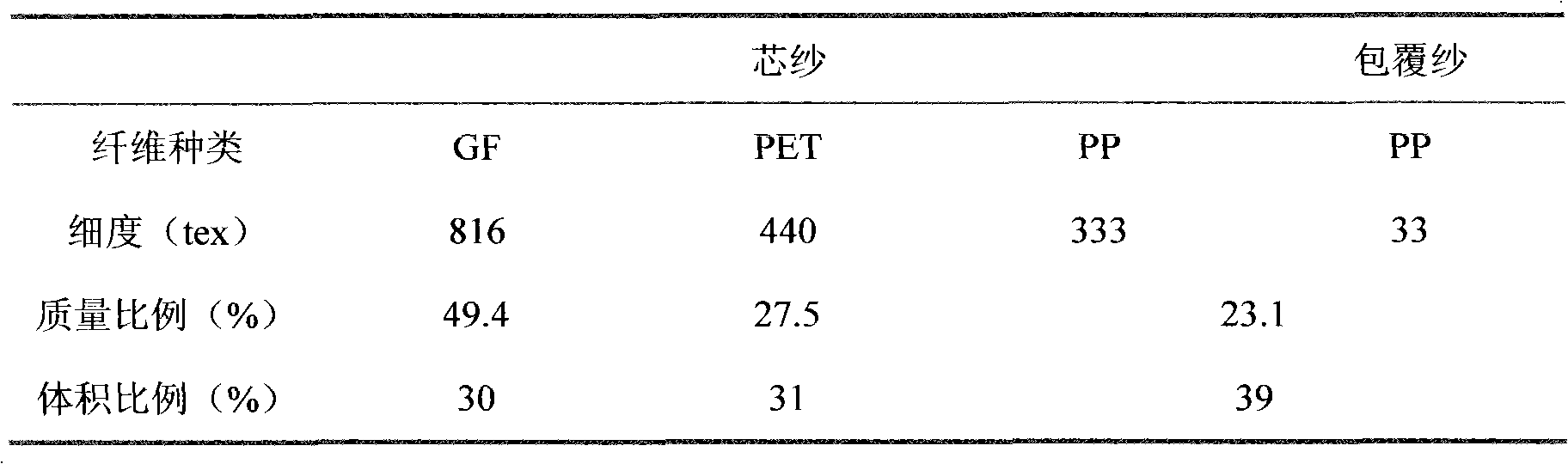

[0019] A method for preparing a thermoplastic fiber hybrid woven composite material, comprising three steps of making a thermoplastic wrapping yarn, weaving a composite material preform, and forming a woven composite material, wherein the thermoplastic wrapping yarn is made of reinforcing fibers Composed of thermoplastic resin fibers, using the existing fiber wrapping technology to mix reinforcing fibers with thermoplastic resin fibers according to the feasible volume ratio, wherein the volume fraction of thermoplastic fibers is 40%, and the volume fraction of reinforcing fibers is 60%, and then adopt The thermoplastic resin fiber is evenly coated on the reinforcing fiber to form a thermoplastic wrapped yarn. Using a fancy twister, the three filament fibers of industrial polyester (PET), glass fiber (GF), and polypropylene (PP) are combined without twisting at a volume ratio of 3:3:4, and then thermoplastic resin fibers are used The wrapping yarn with hybrid effect is obtained...

Embodiment 2

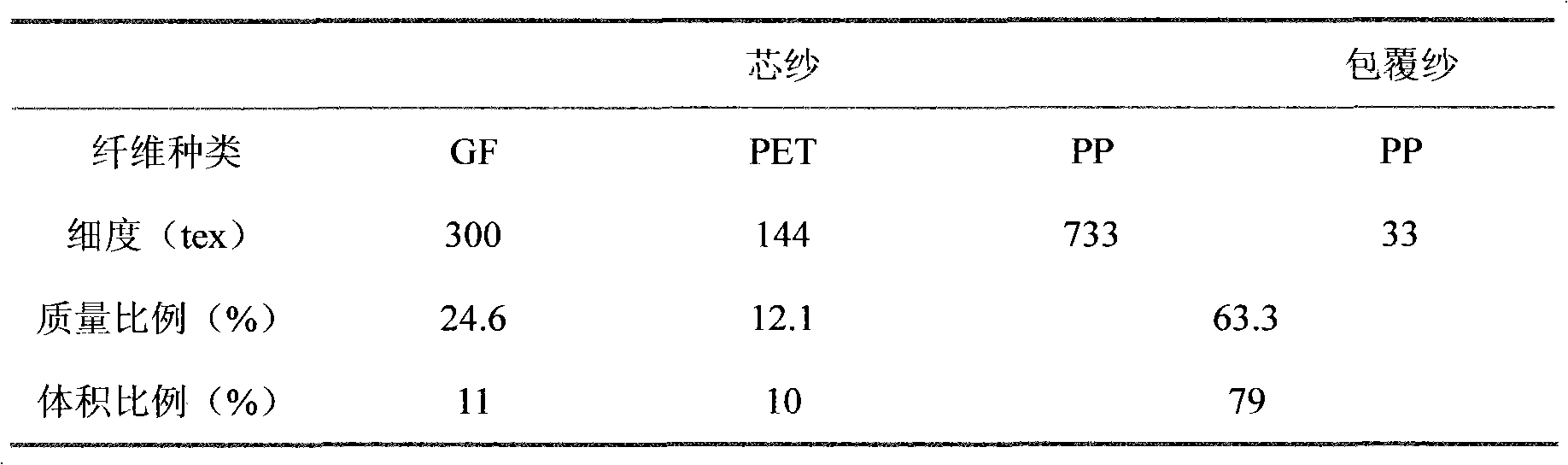

[0025] A method for preparing a thermoplastic fiber hybrid woven composite material, comprising three steps of making a thermoplastic wrapping yarn, weaving a composite material preform, and forming a woven composite material, wherein the thermoplastic wrapping yarn is made of reinforcing fibers Composed of thermoplastic resin fibers, using the existing fiber wrapping technology to mix reinforcing fibers with thermoplastic resin fibers according to the feasible volume ratio, wherein the volume fraction of thermoplastic fibers is 80%, and the volume fraction of reinforcing fibers is 20%, and then adopt The thermoplastic resin fiber is evenly coated on the reinforcing fiber to form a thermoplastic wrapped yarn. Using a fancy twister, the three filament fibers of industrial polyester (PET), glass fiber (GF), and polypropylene (PP) are combined without twisting at a volume ratio of 1:1:8, and then thermoplastic resin fiber PP Filament covering produces wrapped yarns with a hybrid ...

Embodiment 3

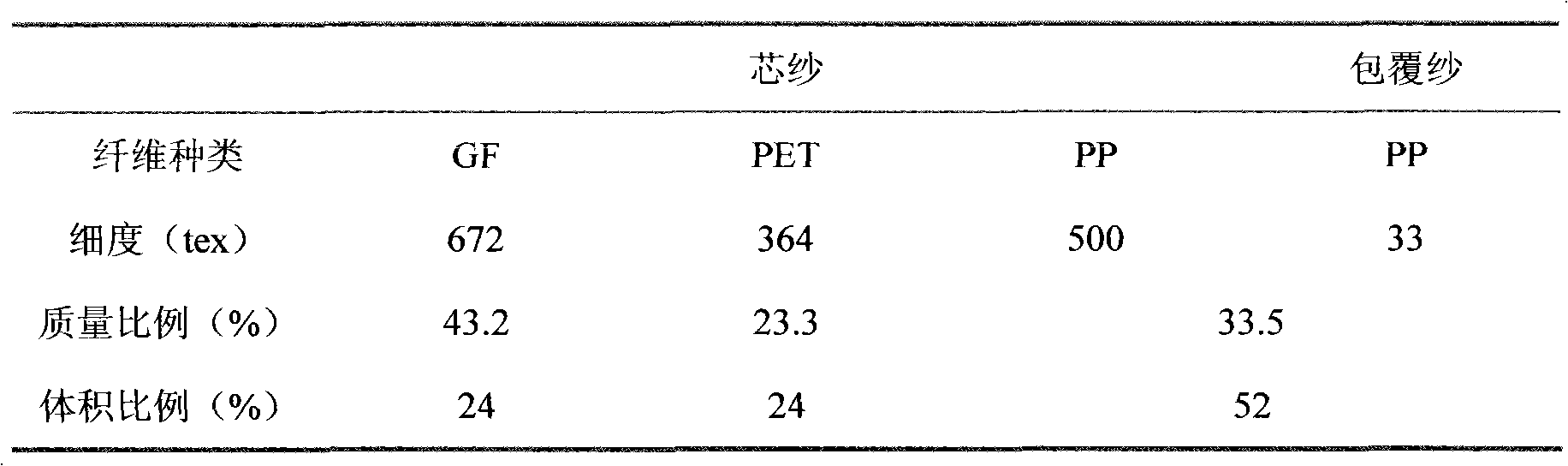

[0031] A method for preparing a thermoplastic fiber hybrid woven composite material, comprising three steps of making a thermoplastic fiber yarn, weaving a composite material preform and forming a woven composite material, wherein the thermoplastic yarn is made of reinforcing fibers and Composed of thermoplastic resin fibers, using the existing fiber wrapping technology to mix reinforcing fibers with thermoplastic resin fibers according to the feasible volume ratio, wherein the volume fraction of thermoplastic fibers is 50%, the volume fraction of reinforcing fibers is 50%, and then adopt thermoplastic The resin fibers are evenly coated on the reinforcing fibers to form thermoplastic wrapped yarns. Using a fancy twister, the three filament fibers of reinforced fiber glass fiber (GF), carbon fiber (CF) and polypropylene (PP) are combined without twisting at a volume ratio of 1:1:2, and then thermoplastic resin fiber PP Filament covering produces wrapped yarns with a hybrid effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com