Grafted copolymer with modified amino and preparation method and application thereof

A graft copolymer and amino modification technology, applied in the field of amino modified graft copolymers, can solve the problems of material becoming brittle and brittle, reducing the effect of repeated use and service life of materials, and achieving the benefits of recycling, fast recycling, etc. The effect of adsorption rate and good extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1 Pre-irradiation emulsion grafting GMA to prepare adsorption material

[0061] 1. In the air, irradiate PE / PP non-woven fabric, PE non-woven fabric, PE fiber, PE film and cotton cloth with electron beam at room temperature, and the irradiation dose is 30kGy.

[0062] 2. Add 378mL of distilled water, 2.0mL of Tween-20, and 20mL of glycidyl methacrylate (GMA) into the Erlenmeyer flask, and stir for 1 hour to disperse the GMA evenly. Add 4.3 g of each of the above-mentioned polymer substrates that have been pre-irradiated therein, blow nitrogen gas for 15 minutes to remove oxygen, and seal. The system was stirred and reacted in a water bath at 55°C for 15 minutes. The grafted material was taken out, extracted with acetone for 48 hours, and then placed in a vacuum desiccator for 24 hours. The grafting rate calculated by weighing method is 170% for PE / PP non-woven fabric, 195% for PE non-woven fabric, 150% for PE fiber, 100% for PE film, and 50% for cotton cloth. ...

Embodiment 2

[0066] Example 2 Pre-irradiation emulsion grafting GMA to prepare adsorption material

[0067]1. Prepare GMA-grafted PE non-woven fabric according to steps 1-3 of Example 1.

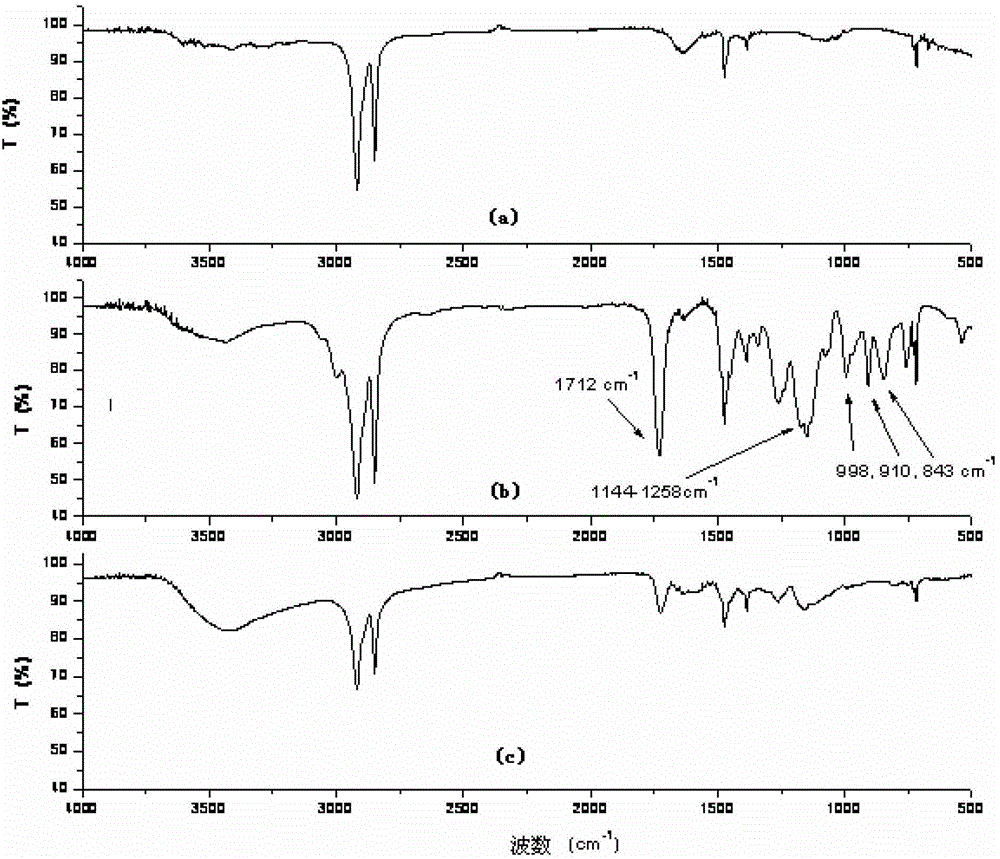

[0068] 2. Similarly, weigh 6.3g of grafted PE non-woven fabric, add it to the 1,4-dioxane solution of triethylenetetramine (TETA) with a volume concentration of 50%, and place it at a constant temperature of 80°C React in a water bath for 2h. The non-woven fabric washed with water was transferred to a vacuum oven at 60°C and dried to a constant weight to obtain a TETA modified material. Infrared detection was carried out on the modified material, and the results of the characteristic absorption wavenumber of the amine group were the same as figure 1 (c).

Embodiment 3

[0069] Example 3 Pre-irradiation emulsion grafting GMA to prepare adsorption material

[0070] 1. Prepare GMA-grafted PE non-woven fabric according to steps 1-3 of Example 1.

[0071] 2. Similarly, weigh 6.3g of grafted PE non-woven fabric, add it to an aqueous solution of diethylamine (DEA) with a volume concentration of 50%, and place it in a constant temperature water bath at 30°C for 5 hours. The non-woven fabric washed with water was transferred to a vacuum oven and dried at 60° C. to a constant weight to obtain a DEA modified material. Infrared detection was carried out on the modified material, and the results of the characteristic absorption wavenumber of the amine group were the same as figure 1 (c).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com