Simulation system for spot welding invalidity number value

A numerical simulation and connection failure technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as the inability to flexibly judge the critical value of solder joint failure, the inability to consider the strengthening effect of the strain rate effect, and the calculation error. To achieve the effect of convenient determination, easy implementation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

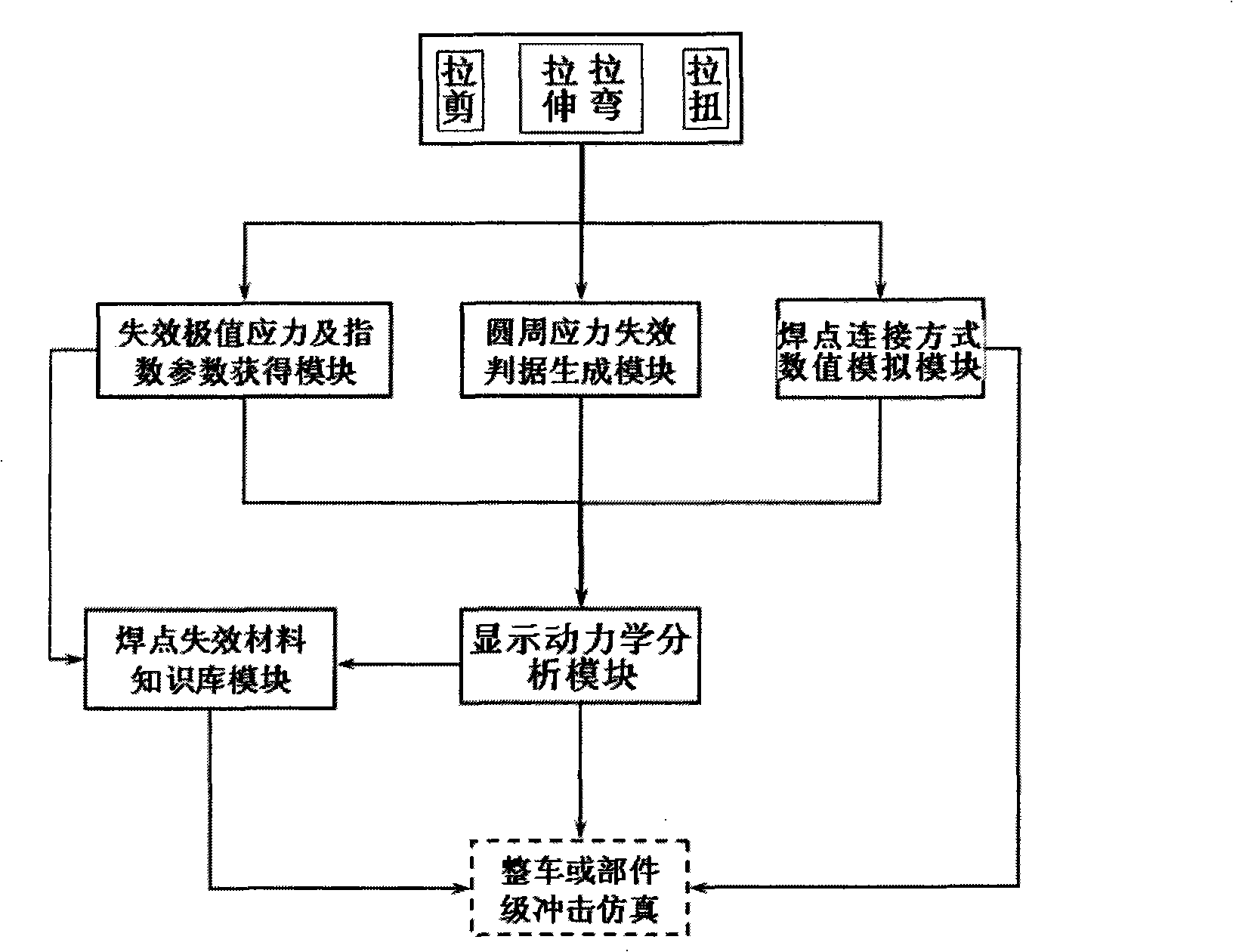

[0037] Such as figure 1 As shown, this embodiment includes: a circumferential stress failure criterion generation module, a failure extreme stress and index parameter acquisition module, a numerical simulation module of solder joint connection mode, an explicit dynamic analysis module, and a solder joint failure material knowledge base module, wherein :

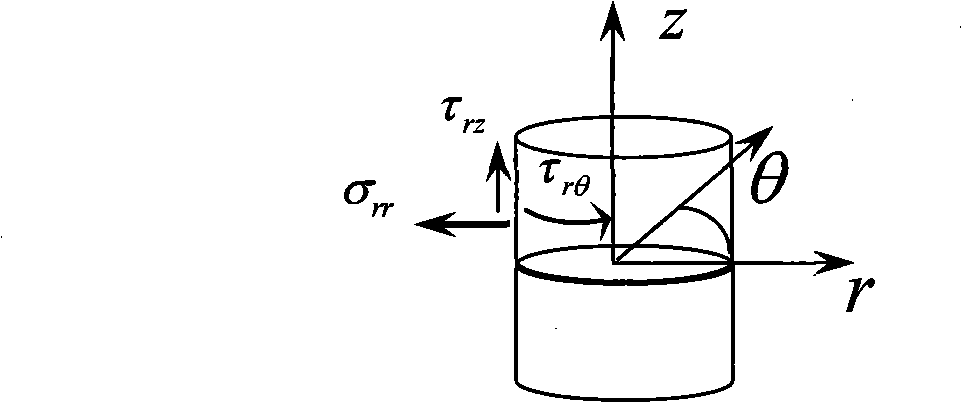

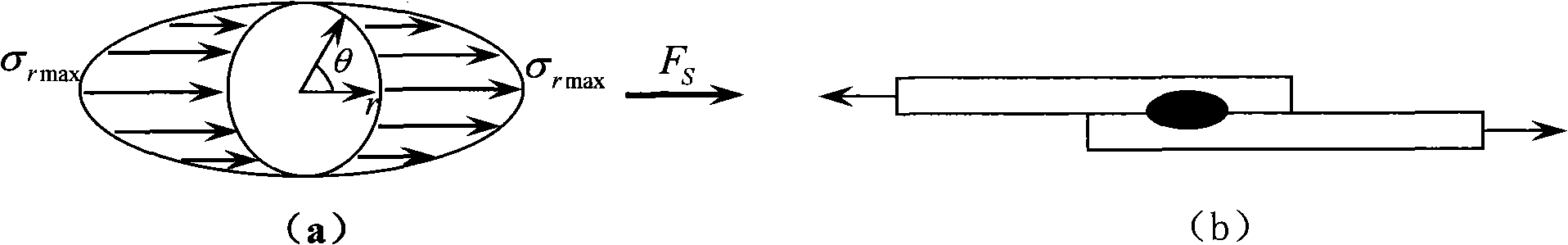

[0038] Circumferential stress failure criterion generation module obtains the weld nugget according to the actual failure mode (circumferential tearing of the weld nugget) of the spot welding connection in the impac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com