Hub unit for wheel

A hub unit and wheel technology, applied in the direction of wheels, axles, bearing components, etc., can solve problems such as increased torque or noise, shortened bearing life, track deformation, etc., to achieve the effects of preventing pressure failure, easy assembly, and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, a wheel hub unit according to an embodiment of the present invention will be described with reference to the accompanying drawings.

[0034] In this specification, the flange side of the wheel hub unit on which the wheel is mounted and which generally faces the outside of the vehicle body in the state where the wheel hub unit is mounted on the vehicle body is referred to as the outer side, and the opposite side toward the center of the vehicle is referred to as the outer side. inside.

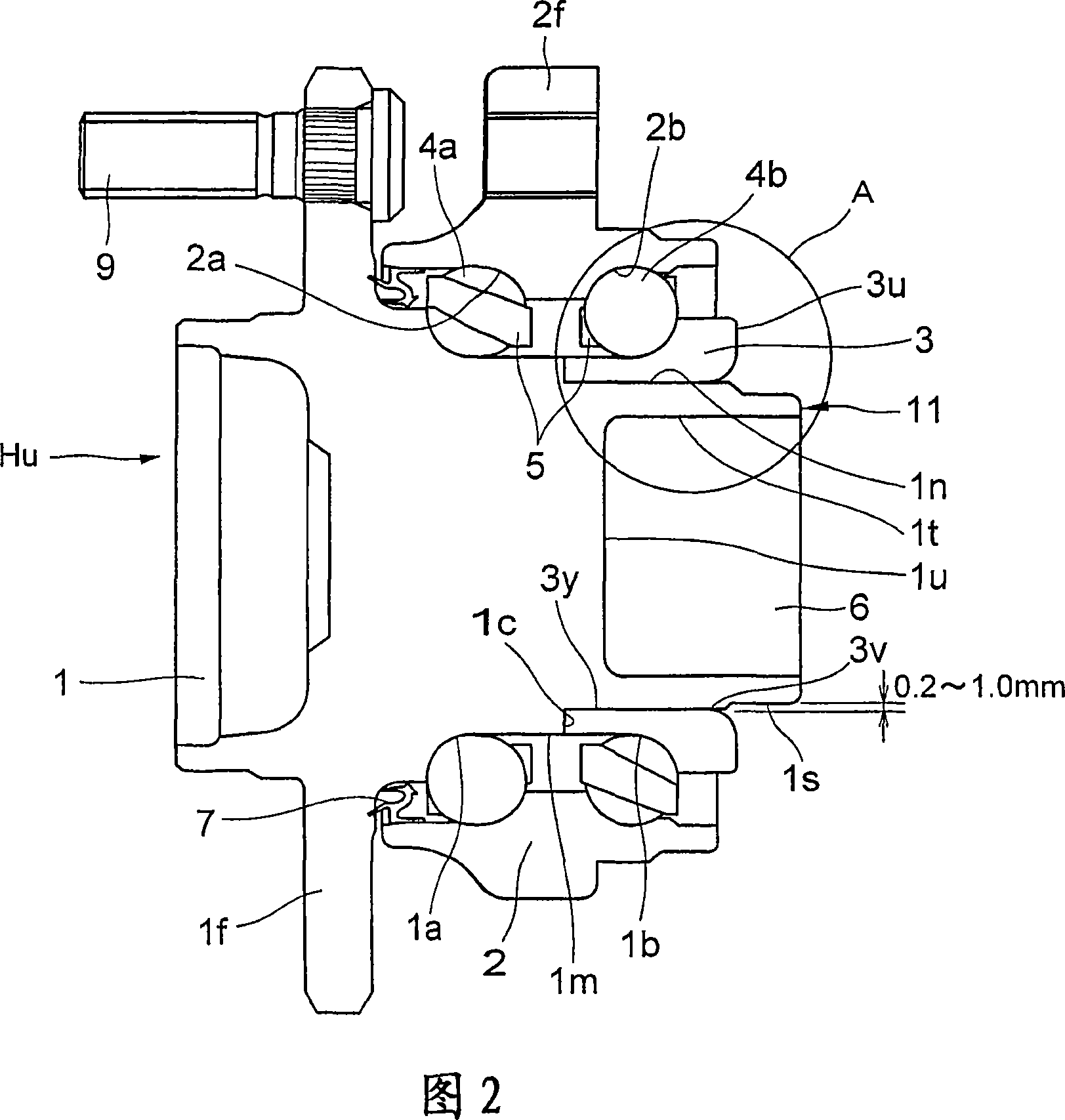

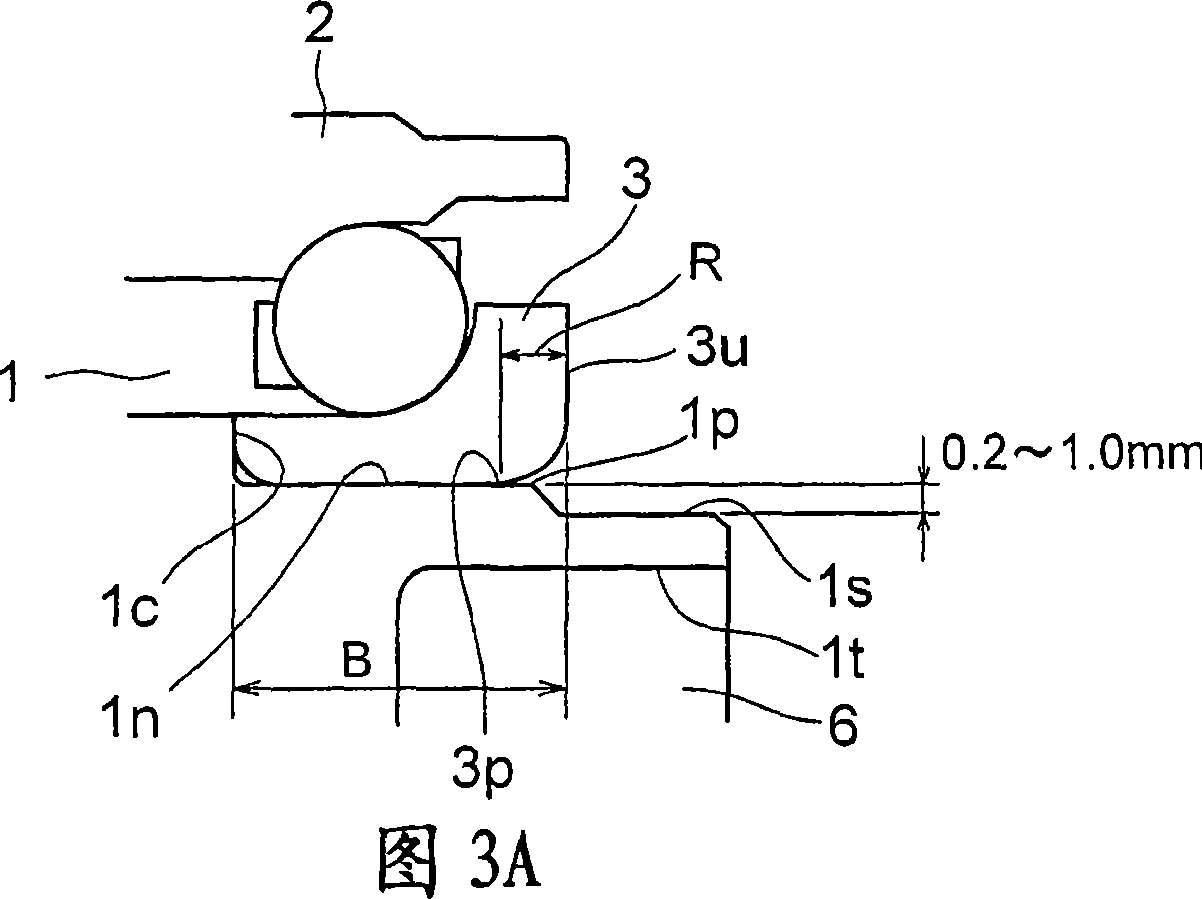

[0035] Next, a first embodiment of the present invention will be described with reference to FIGS. 1 and 3A-3C.

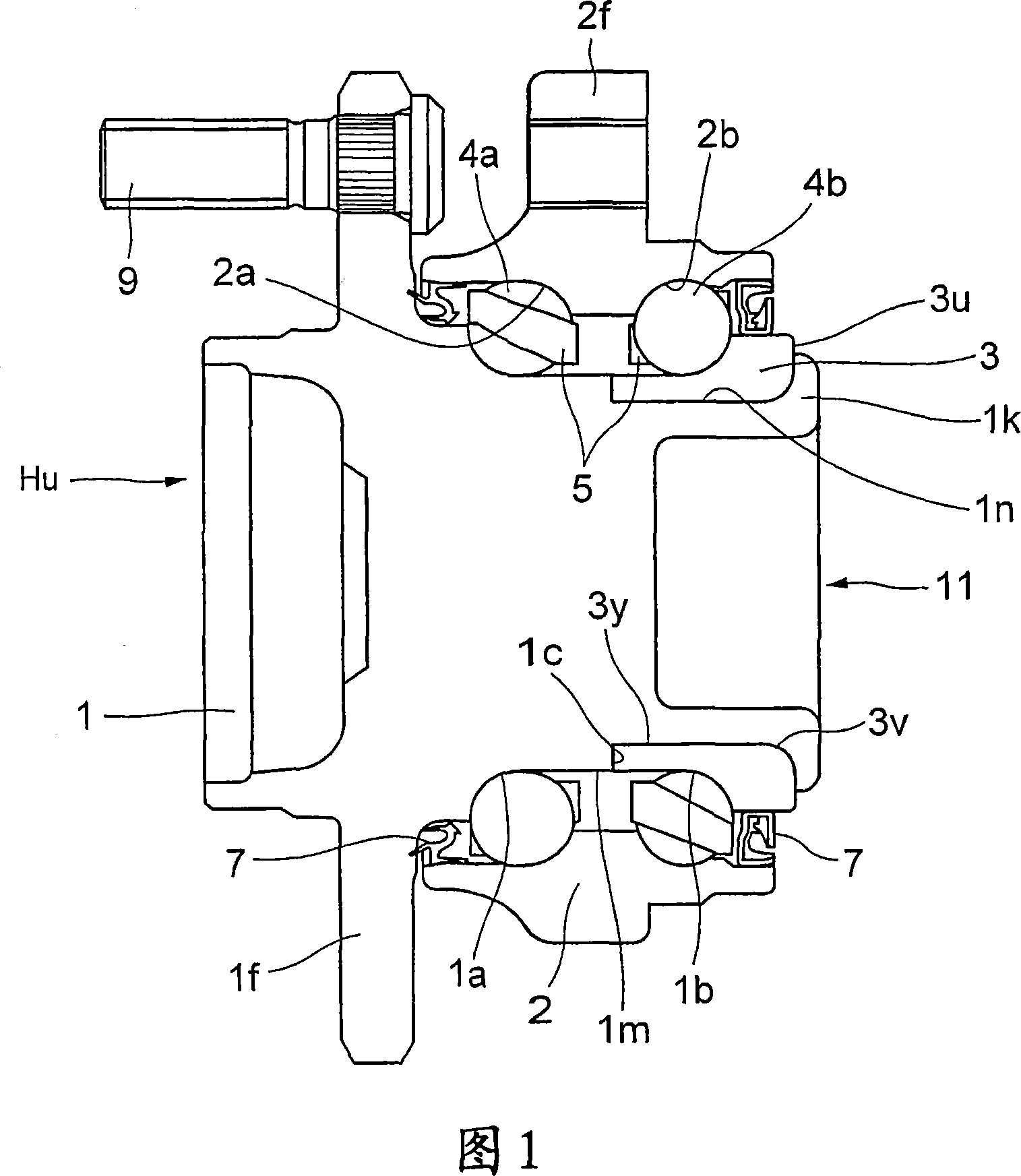

[0036] FIG. 1 is a cross-sectional view of a wheel hub unit Hu according to the first embodiment.

[0037] In FIG. 1, the hub 1 is formed with a flange 1f for mounting a wheel (not shown) on the outer end side thereof. The first bearing rail 1a is directly provided on the flange-side outer peripheral surface, which is a part of the outer peripheral surface 1m o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com