Anti-buckling coiling machine strip steel threading tension control method

A tension control and coiler technology, applied in metal material coating process, hot dip plating process, coating and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

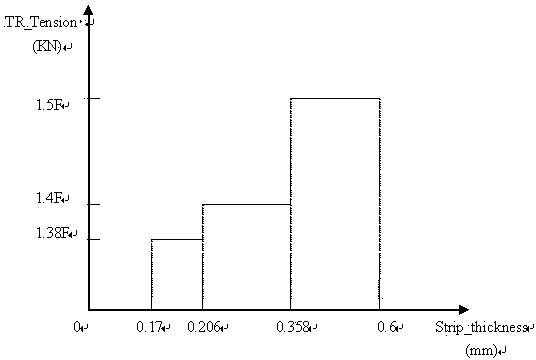

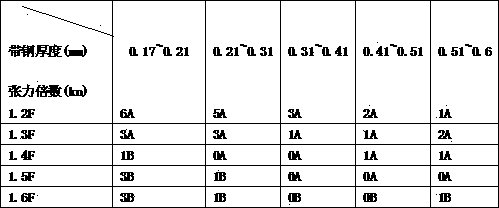

[0032] Coiler threading tension control method to prevent collapse phenomenon, control the coiler threading tension according to the thickness of the strip, when the thickness is below 0.206mm, use the threading tension of 1.38 times the set tension, and the thickness is 0.206mm When the thickness is between 0.358mm and 0.358mm, the threading tension is 1.4 times the set tension; when the thickness is above 0.3580mm, the threading tension is 1.5 times the set tension.

[0033] The system automatically judges the thickness grade of strip steel based on the incoming thickness data of the strip steel, and transmits the corresponding set value of threading tension to the tension parameter variable. The threading tension of the specification strip. In this way, by controlling the threading tension of the coiler, the collapse of the coil caused by improper threading tension can be effectively avoided.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com