Die Cast Rotor With Steel End Rings to Contain Aluminum

a technology of aluminum end rings and die cast rotors, which is applied in the direction of magnetic circuit rotating parts, synchronous motors, magnetic circuit shapes/forms/construction, etc., can solve the problems of rotor bars not experiencing the same amount of radial growth, fatigue stress, failure of the machine, etc., and achieve the effect of reducing hoop stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

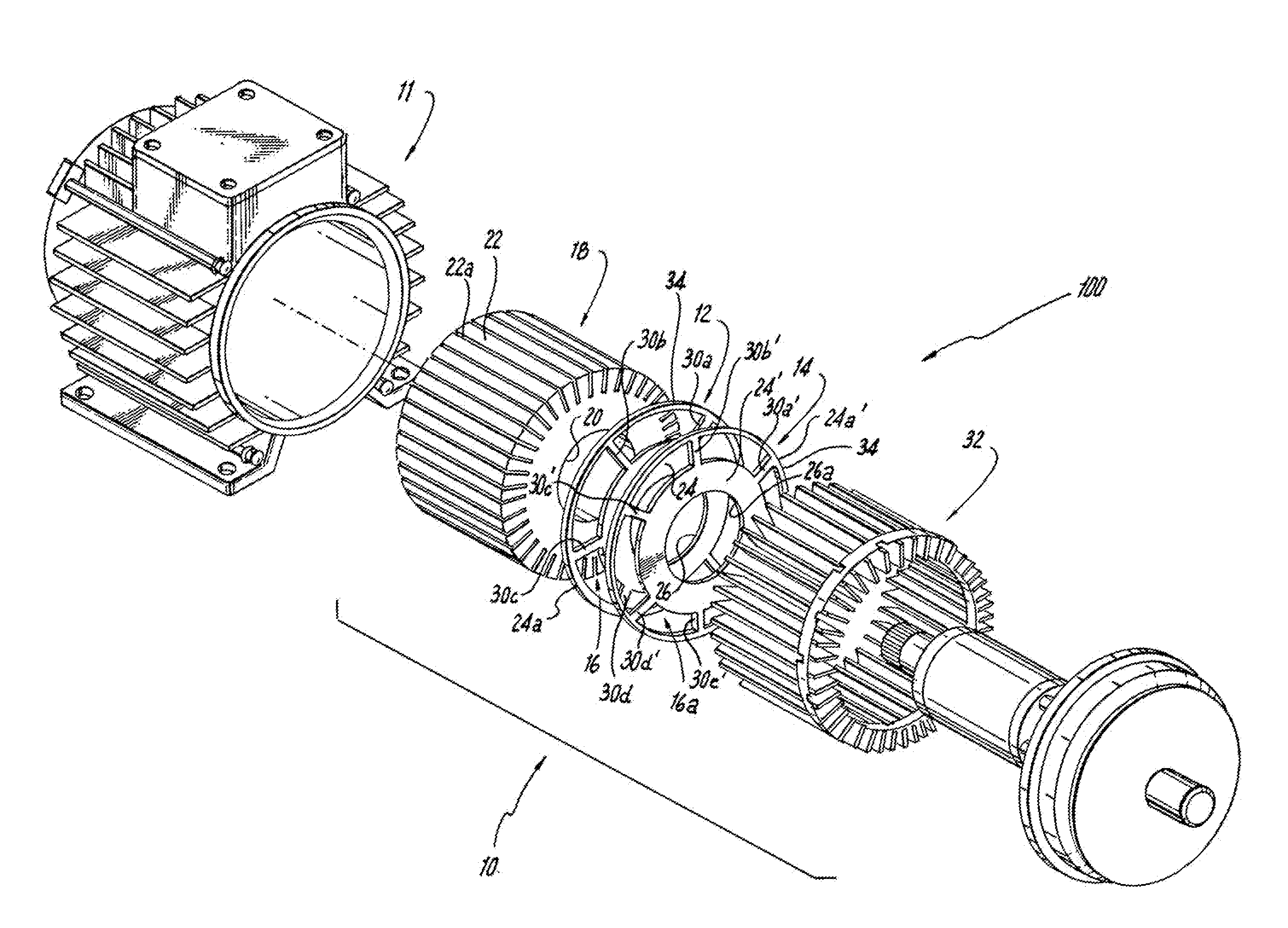

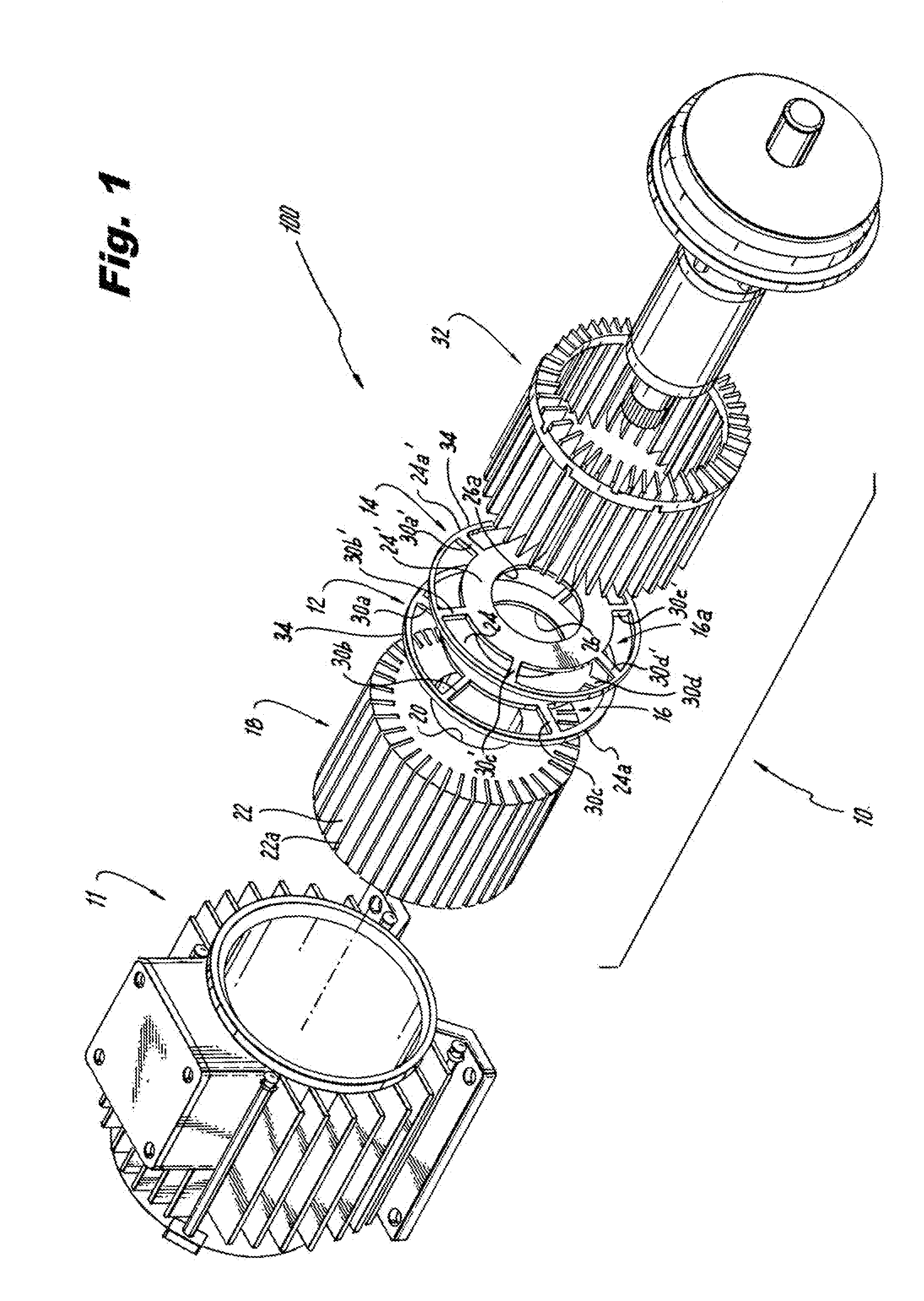

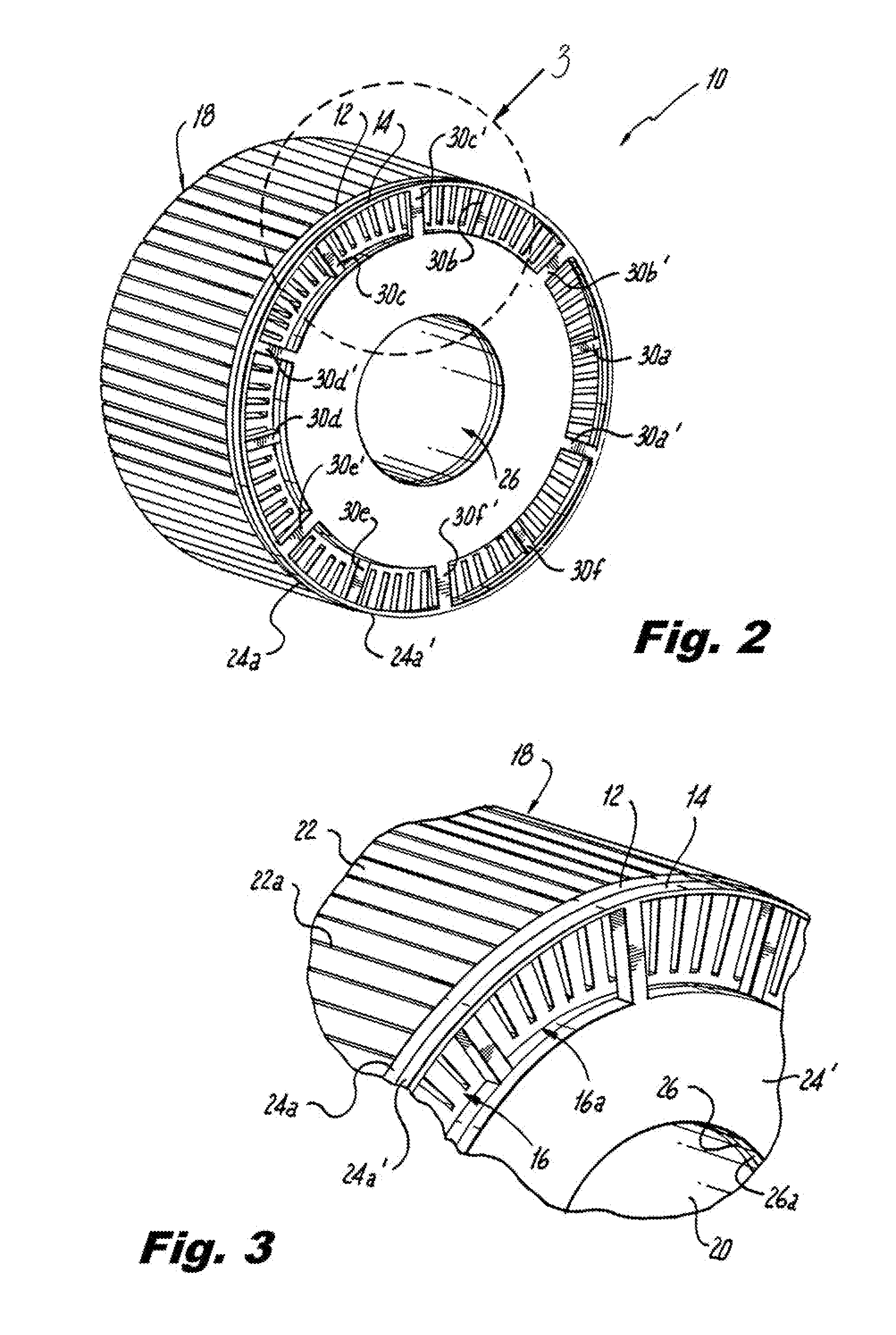

[0016]The present disclosure is directed to an electric machine 100 such as an induction motor or generator having a rotor 10 and a stator 11. In the illustrated embodiment, the rotor 10 is advantageously cast from pure aluminum, which encompasses a first and a second end ring 12, 14 made preferably from steel or a steel alloy. It should be appreciated that the present disclosure is not limited to these specific materials, and other suitable materials can be used to form the rotor 10. The steel end rings 12, 14 preferably are adapted to contain the aluminum at high speeds of rotation by breaking up the end rings 12, 14 into one or more pockets 16, 16a to reduce hoop stresses caused by thermal fatigue. It should be appreciated that casting with pure aluminum using the steel end rings 12; 14 preferably provides several benefits. First, suitable mechanical strength is provided by the end rings 12, 14, while the aluminum provides suitable casting, thermal, and electrical properties. Thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com