Spherical hinge movement direction measuring method based on spherical capacitor

A spherical hinge and measurement method technology, applied in the field of measurement, can solve problems such as installation space and working environment limitations, research scheme limitations, complex construction systems, etc., and achieve the effects of compact structure, reduced installation space requirements, and high measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

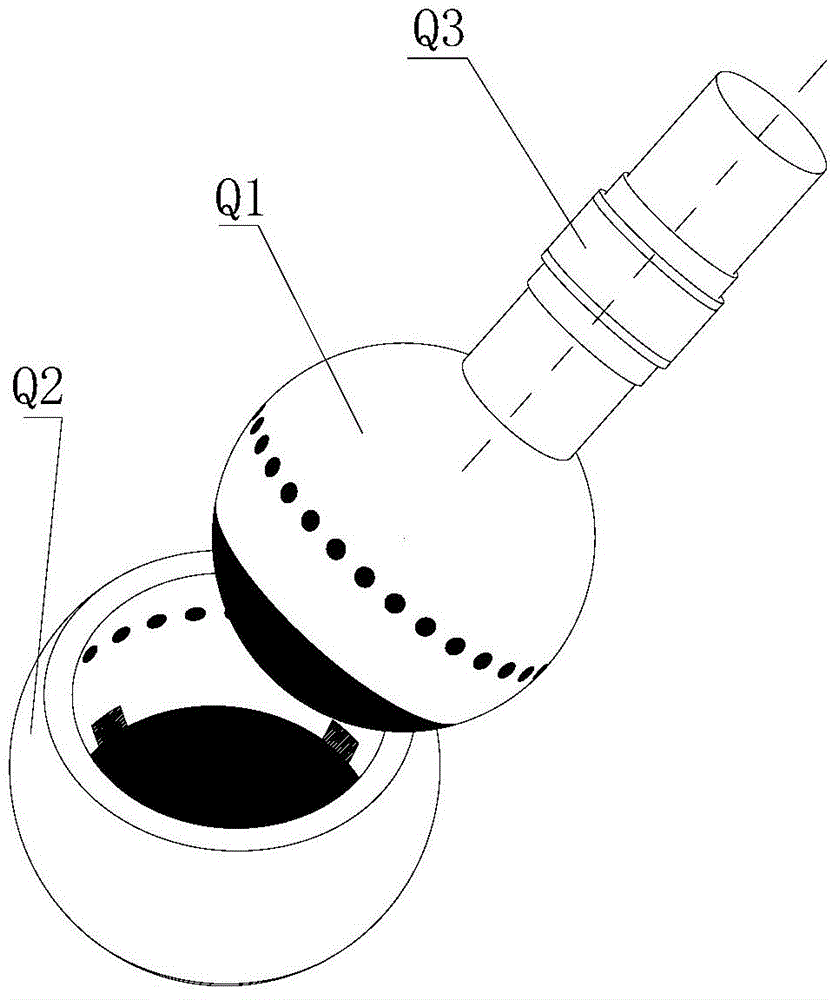

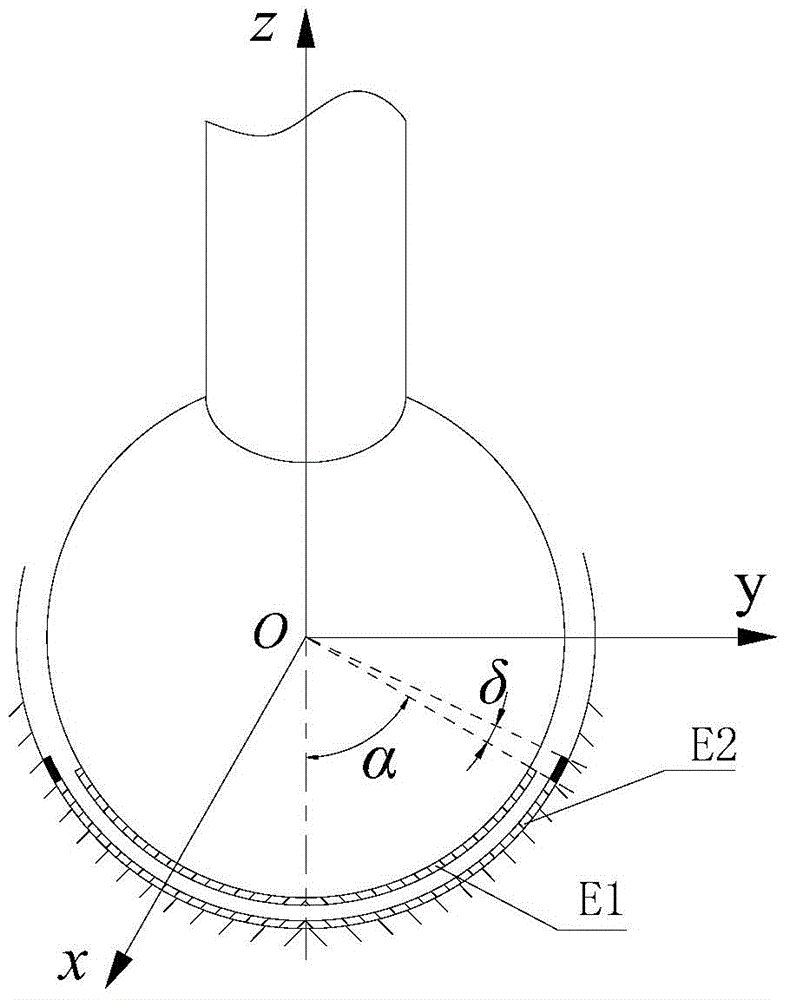

[0022] Such as figure 1 and 2 As shown, a method for measuring the motion orientation of a spherical hinge based on spherical capacitance, the first spherical cap sensor electrode E1 is arranged at the bottom of the ball head Q1 of the spherical hinge, and the second spherical capacitive electrode E1 is arranged at the bottom of the ball socket Q2 Electrode E2; the corresponding central angle between the center and edge of the spherical cap of the first spherical capacitive sensing electrode E1 and the second spherical capacitive electrode E2 is α=60°. Due to the structural limitation of the spherical hinge, the value range of the angle ψ between the output rod to be measured and the positive direction of the z-axis generally does not exceed 60°, so the effective range of the first spherical capacitive sensing electrode and the second spherical capacitive electrode The detection area is large enough to meet the measurement requirements.

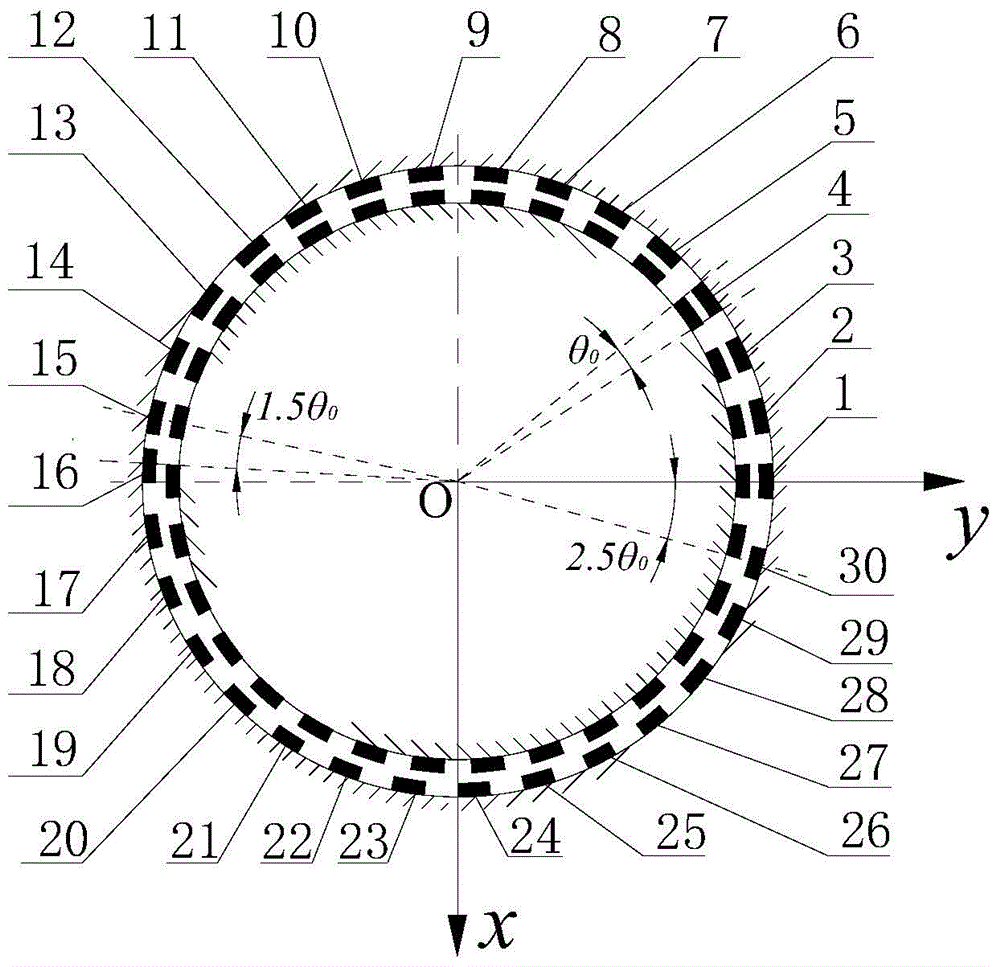

[0023] Such as image 3 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com