Electromagnetic ultrasonic non-contact automatic detector for welding seams of bottom plates of storage tanks

An electromagnetic ultrasonic and storage tank bottom plate technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and re-radiation of electromagnetic waves. Problems such as low detection efficiency of tank bottom plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be further described:

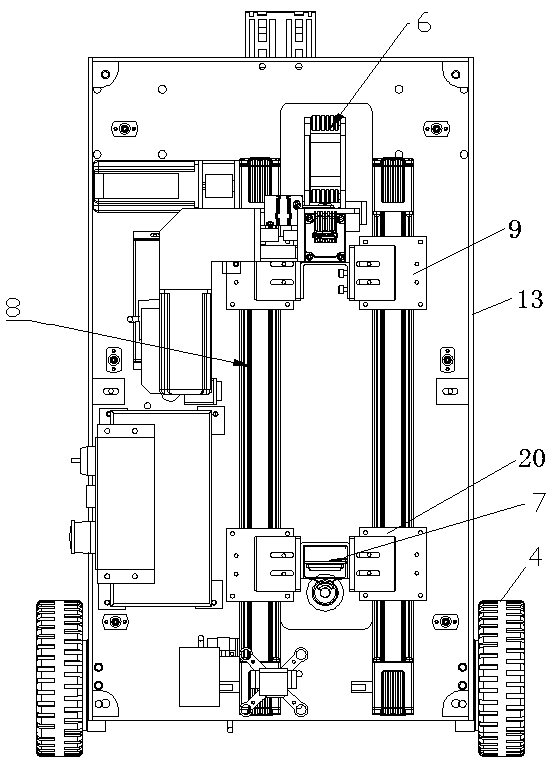

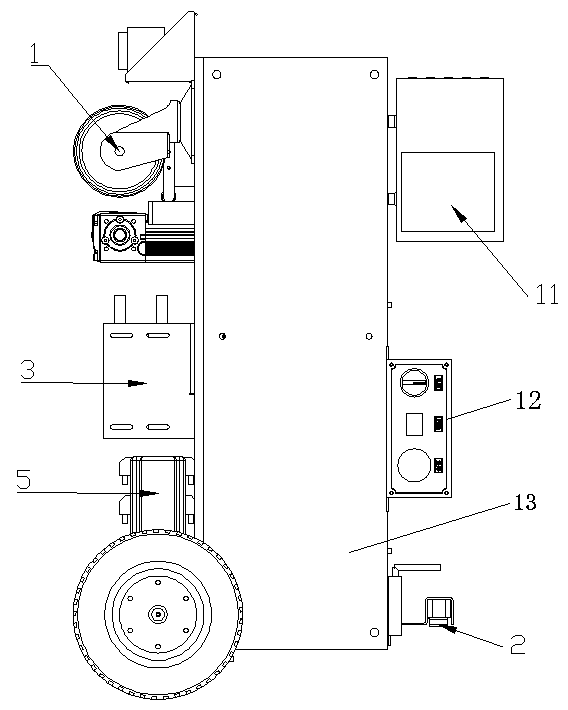

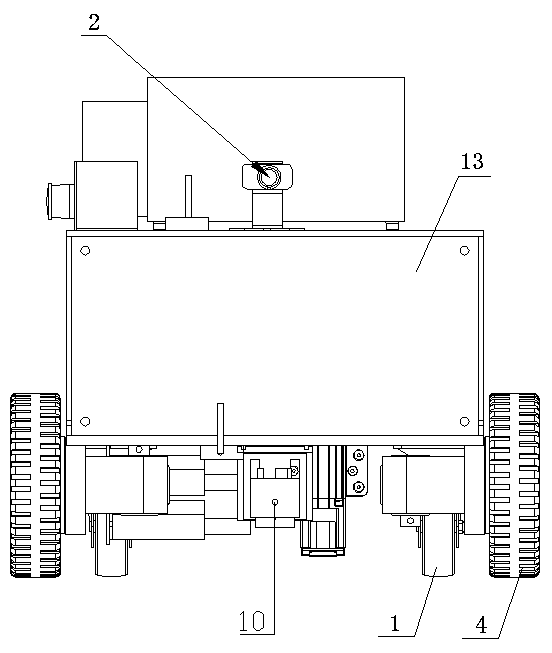

[0026] combine figure 1 , figure 2 , image 3 , Figure 9 As shown, this electromagnetic ultrasonic non-contact automatic detector for the weld of the bottom plate of the storage tank includes a body 13, a traveling mechanism, a non-destructive testing mechanism, a cleaning mechanism 7, a positioning structure, a control mechanism 3, a visual monitoring structure, and a data processor. Body 13 both sides are provided with walking mechanism, and the pan-tilt camera 2 of positioning mechanism and lidar are installed on the front end of body 13 tops, and the camera 10 of visual monitoring structure is installed in body 13 bottom, is used for observing weld seam; The guide rail 8 and the control mechanism 3 respectively control the traveling mechanism, the nondestructive testing mechanism, and the cleaning mechanism 7; the electromagnetic ultrasonic probe 6 is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com