Two-way tensioner applied to BSG wheel system and vehicle engine system

A tensioner and engine technology, applied in mechanical equipment, transmission, belts/chains/gears, etc., can solve the problems of affecting the normal start and stop of the engine, difficulty in swapping the elastic side, and belt slippage, etc., to facilitate quick start and stop , compact structure, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

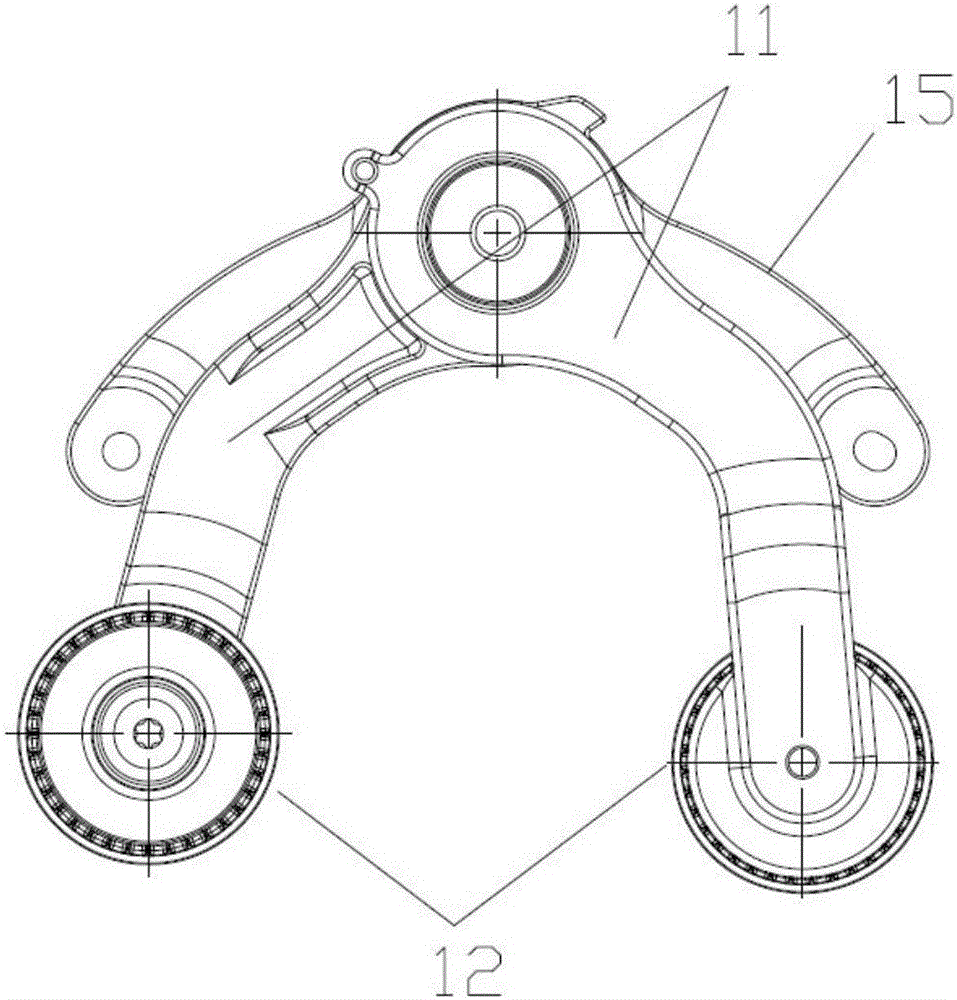

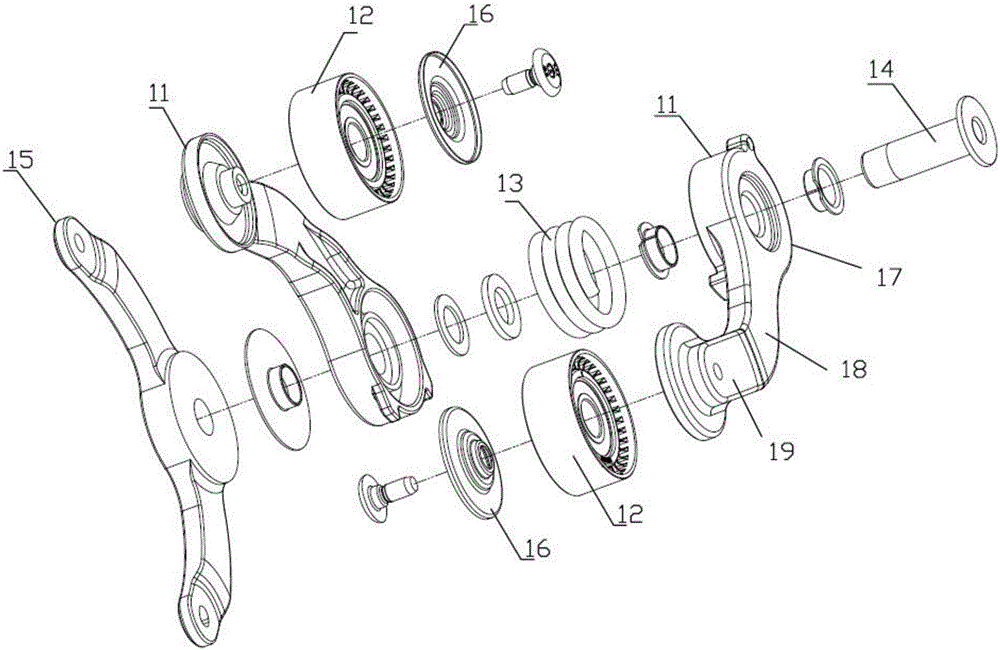

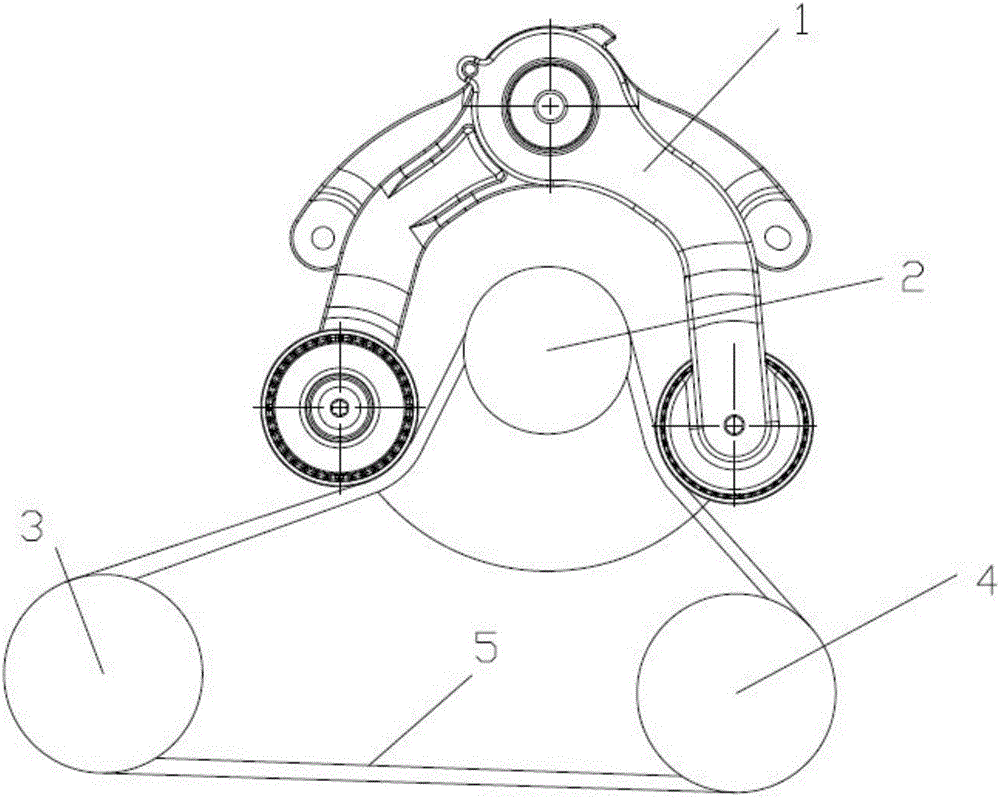

[0027] As mentioned in the background technology section, in the BSG system, the motor needs to act as a power exporter. The motor starts when starting, provides power when assisting, and charges the motor during normal operation and energy recovery. Therefore, there are loose side and tight side interchanges in the front wheel train. In the traditional way, only one side tensioner is used to realize the tensioning of the transmission belt. Problems such as skidding affect the normal start and stop of the engine.

[0028] Aiming at the deficiencies in the prior art, the present invention provides a two-way tensioner applied to BSG gear trains, which realizes tensioning on both sides of the motor by using two swinging tensioner arms, and adapts to the left and right sides of the motor due to The elastic side of the belt under different working conditions is interchangeable, easy to install, and the tensioner responds quickly, which is convenient for the rapid start and stop of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com