Electronic control pneumatic type clutch control system and method

A technology of clutch control and control method, applied in the field of clutches, can solve the problems of poor follow-up effect of clutch control, damage to the skin and environment of operators, and increased workload of designers, so as to shorten the response time, achieve universality, The effect of saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

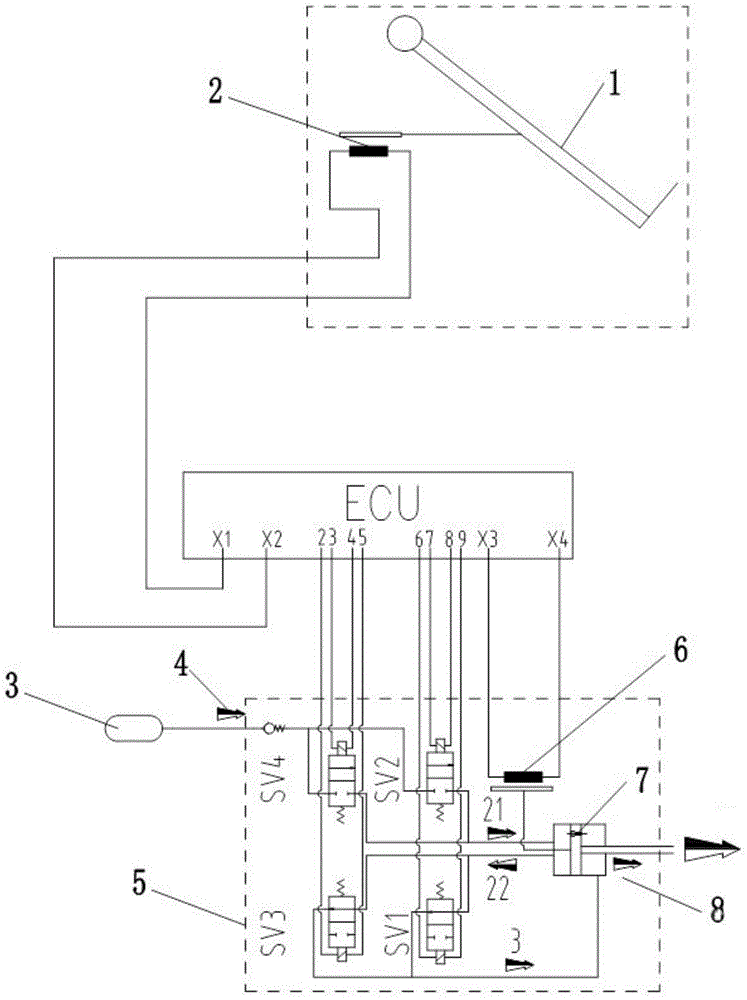

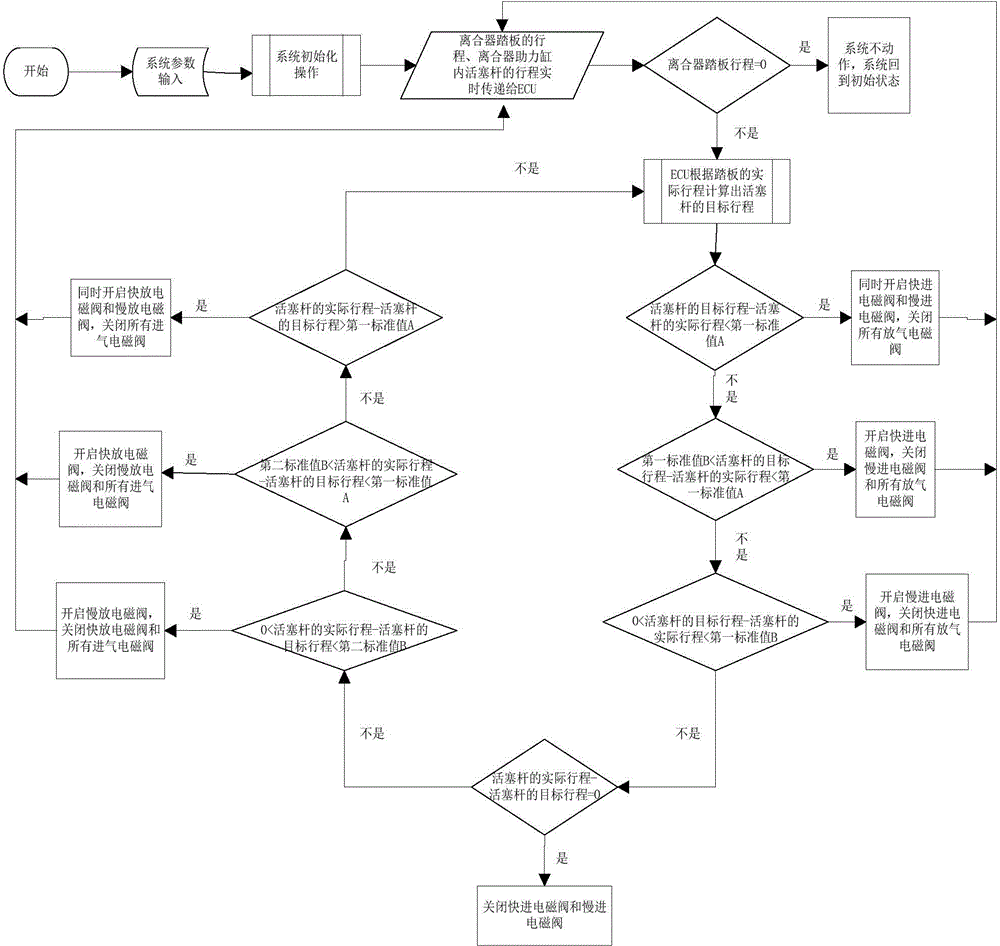

[0043] Such as figure 1 As shown, the electronically controlled pneumatic clutch control system includes an electronic clutch pedal 1, an electronic control unit ECU and a pneumatic clutch actuator. The electronic clutch pedal 1 is provided with a position sensor 2, and the position sensor 2 can be a second displacement sensor or an angle sensor , the position sensor 2 communicates with the electronic control unit ECU to transmit the position information of the pedal to the electronic control unit ECU in time; the pneumatic clutch actuator includes a clutch booster cylinder 5 and an air reservoir 3, and the clutch booster cylinder 5 is provided with an air inlet 4 And the exhaust port 8, the air storage tank 3 is connected with the air inlet 4 of the clutch booster cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com