Three-phase direct-current brushless deep-water motor

A brushless DC, water motor technology, applied in electrical components, electromechanical devices, electric components and other directions, can solve the problems of complex processing and manufacturing process, not economical and practical, and achieve easy production and maintenance, simple structure and high feasibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in more detail below in conjunction with accompanying drawing example:

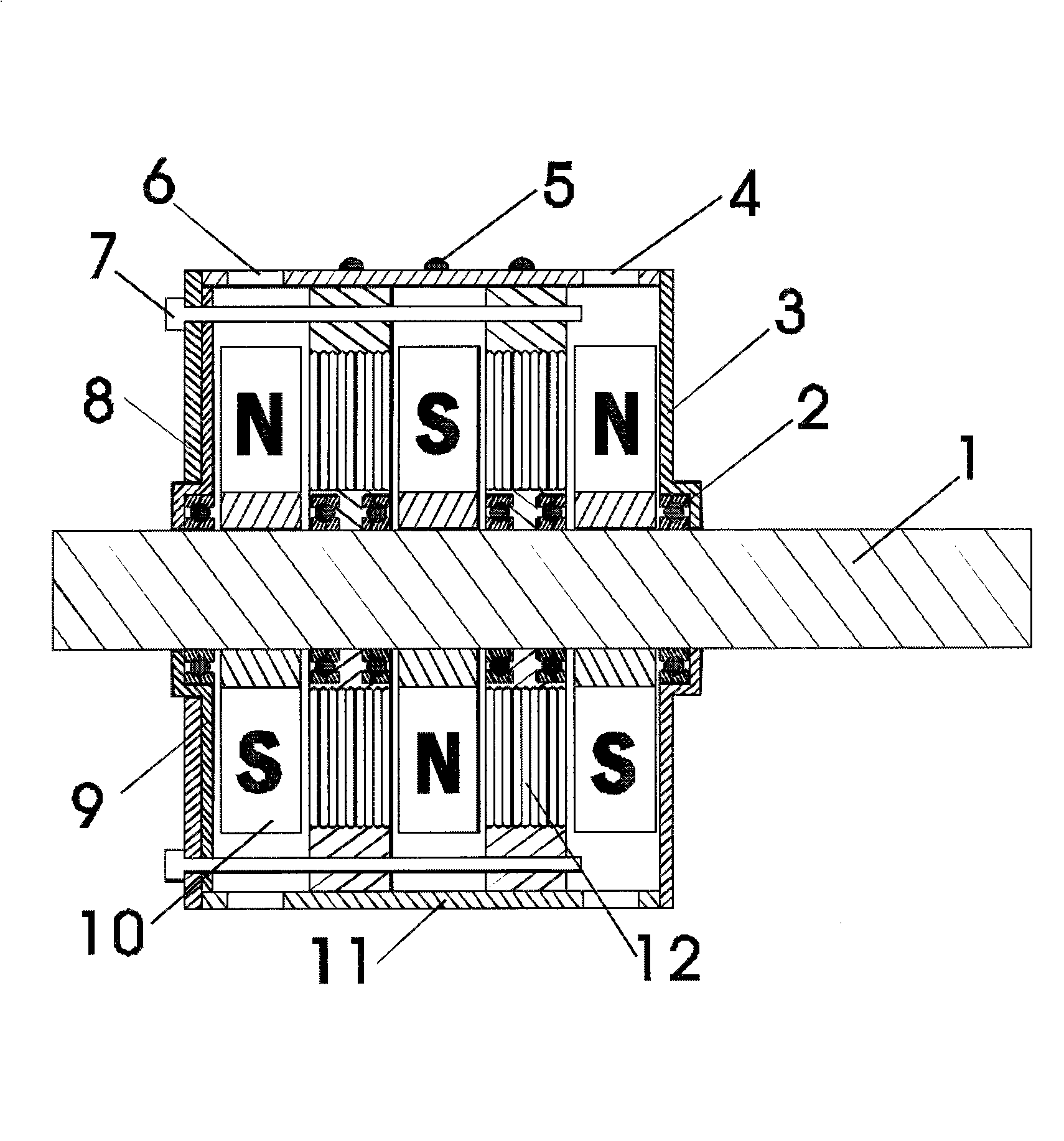

[0021] The composition of the three-phase DC brushless deep-water motor includes: 1 main shaft, 2 bearings, 3 front cover, 4 water inlet, 5 power connector, 6 water outlet, 7 fixed rod, 8 rear cover, 9 fixed plate, 10 magnet Steel rotor disc, 11 casings, 12 stator coil discs. The composition of the motor part includes a main shaft 1 , a magnetic steel rotor disk 10 , and a coil stator disk 12 . The magnetic steel rotor disk has three pieces, and the stator coil disk has two pieces. The magnetic steel rotor disk and the stator coil disk are arranged alternately. The three magnetic steel rotor disks 10 are all fixedly connected to the main shaft. The fixed rod 7 connects the fixed plate 9 together, the fixed plate is connected with the rear cover 8 , and the rear cover is installed on the casing 11 . The front cover 3 is installed at the other end of the casing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com