Automatic processing system for rolled cloth

A processing system and fabric technology, applied in the direction of thin material processing, winding strips, sending objects, etc., can solve the problems of poor processing quality, easy to generate pollution, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

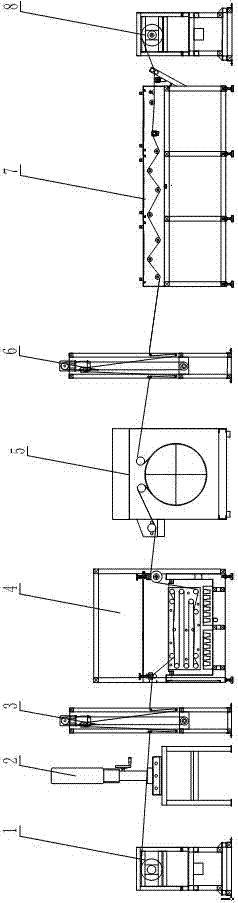

[0013] Such as figure 1 As shown, a roll cloth automatic processing system according to the embodiment of the present invention includes a programmable control device, and the programmable control device is respectively connected with the feeding deviation correction device 1 and the ultrasonic welding device 2 arranged in sequence along the cloth conveying direction. , the feed tension buffer device 3, the ultrasonic cleaning device 4, the drying device 5, the discharge tension buffer device 6, the flattening machine 7, and the receiving deviation correcting device 8 are connected to control the entire production process; the unwinding deviation correcting The device 1 and the winding correction device 8 are respectively provided with photoelectric correction sensors, the feeding tension buffer device 3 and the discharge tension buffer device 6 are respectively provided with tension sensors, and the drying device 5 is provided with a temperature sensor. The flattening machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com