Device and method for manufacturing melting electrostatic spinning nano-fiber non-woven fabrics

A nanofiber and non-woven fabric technology, applied in the non-woven fabric field of the textile field, can solve the problems of not too large melt electrospinning, no melt electrospinning equipment, etc., and achieves easy industrialization promotion, melt belt The effect of uniform power and increased production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

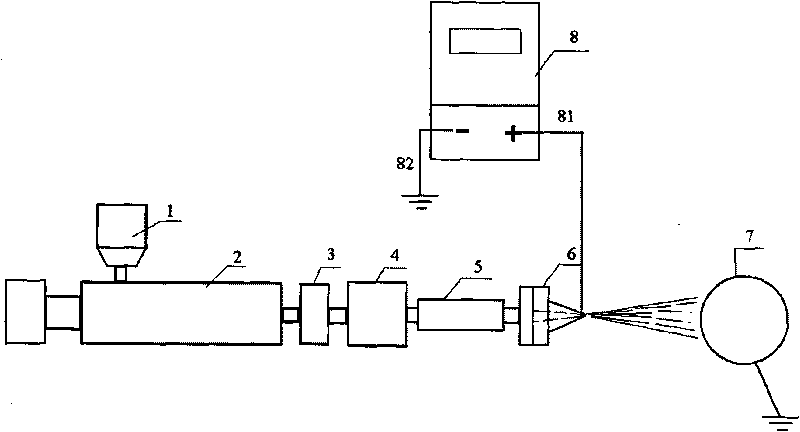

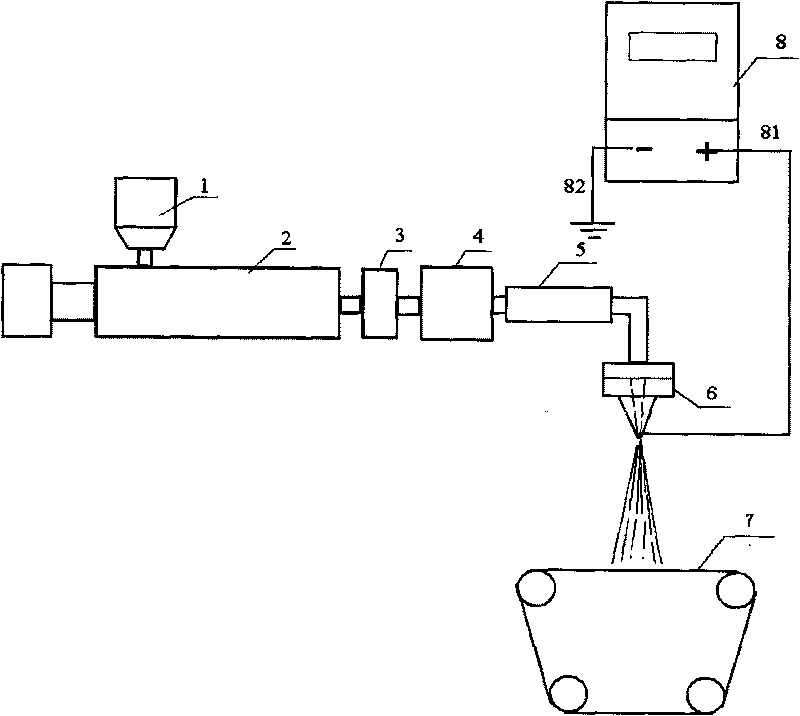

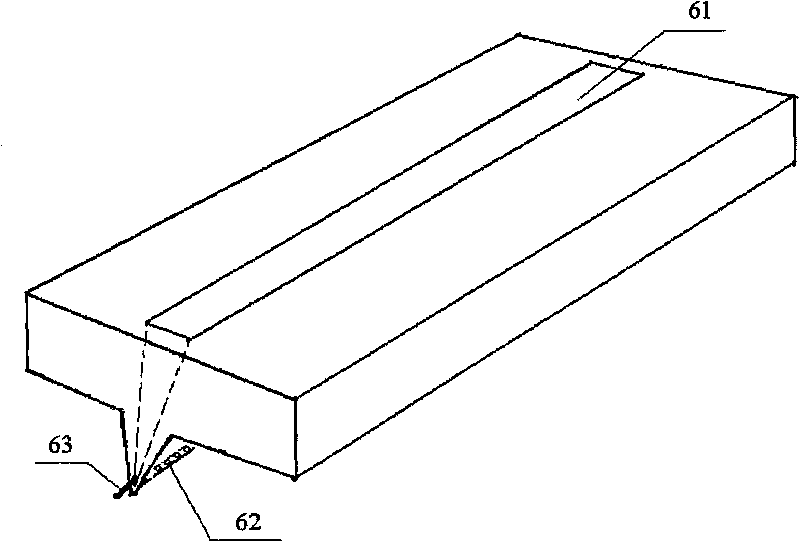

[0047] Such as figure 1 , 2 The manufacturing equipment of a kind of melting electrospinning nanofiber nonwoven fabric shown, comprises material storage box 1, screw extruder 2, filter 3, metering pump 4, material path 5, spinneret assembly 6, receiving device 7 and High voltage electrostatic generator8. When working, mix the dried polymer resin with the metal salt additive accounting for 0.1-1% by mass in a high-speed mixer, and then put it into the storage box 1, and the polymer resin is melted by the screw extruder 2 Extrude, then pass through the filter 3, metering pump 4, and material path 5 to enter the spinneret assembly 6; turn on the high-voltage electrostatic generator 8, set a certain voltage value, and the polymer melt will flow from the spinneret assembly under the action of high-voltage static electricity. 6 spray hole 62 nozzles are sprayed at high speed and medium speed, and are split and drawn under the action of high-voltage electrostatic field to make nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com