Polyphenylene sulfide compound film or fiber and manufacture method thereof

A polyphenylene sulfide and composite film technology, applied in the direction of single-component synthetic polymer rayon, fiber chemical characteristics, textiles and papermaking, can solve the problem of low toughness and tensile elongation at break, polyphenylene sulfide phase Limited capacity, product toughness, and low strength, etc., to achieve the effect of high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

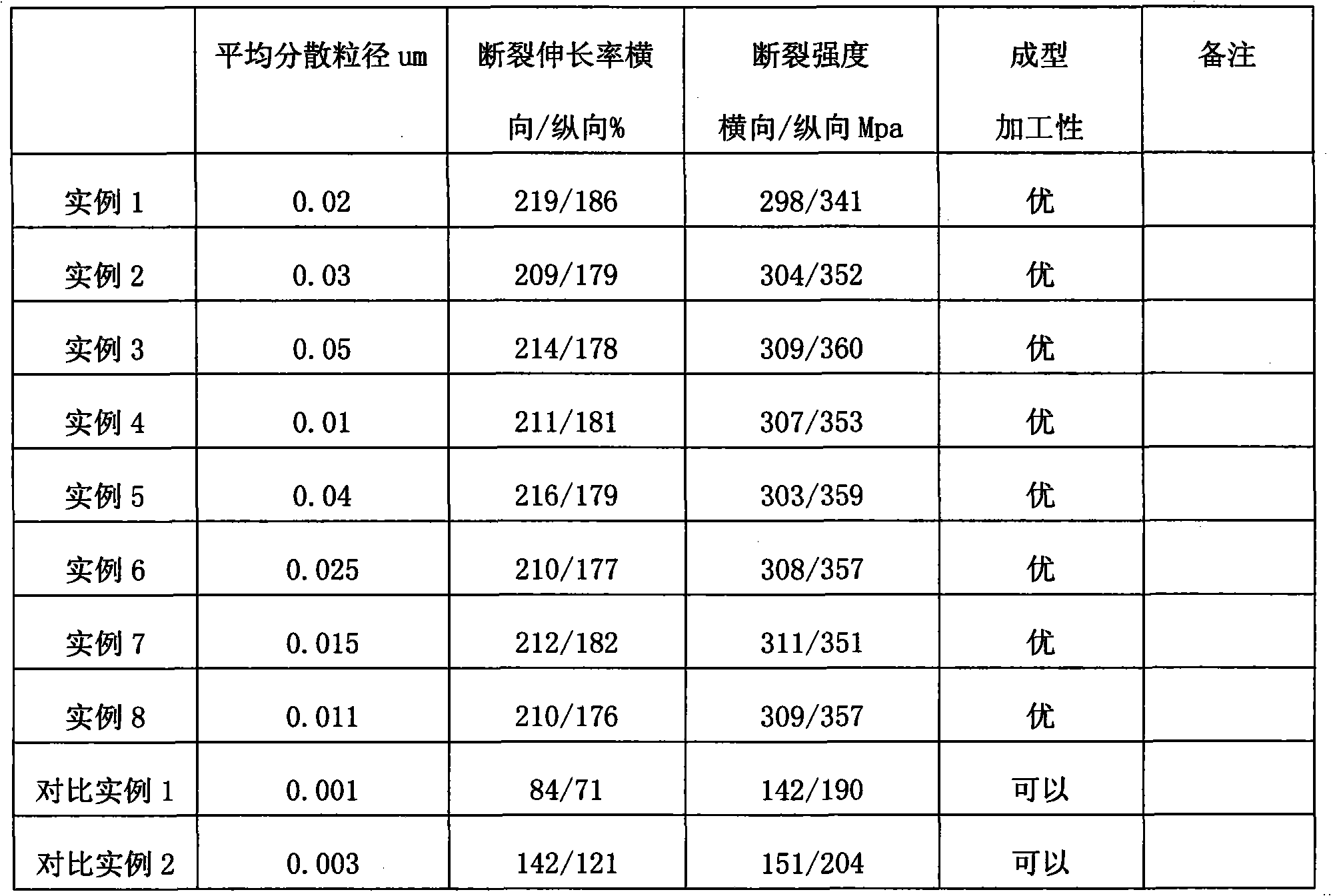

Examples

preparation example Construction

[0046] The preparation of the above-mentioned polyphenylene sulfide resin containing aromatic heterocycles uses sodium sulfide, p-dichlorobenzene, 2-(4-chlorophenyl)-5-chlorohydrin with a molar ratio of 1:0.6-0.9:0.4-0.1 Benzimidazole is used as raw material, N-methyl-2-pyrrolidone is used as solvent, and it is synthesized by polycondensation under the action of alkali metal co-solvent.

[0047] Owing to use 2-(4-chlorophenyl)-5-chlorobenzimidazole as raw material, obtain the polyphenylene sulfide resin containing aromatic heterocycle that polydispersity coefficient is lower, and molecular weight distribution is very narrow, the resin's Crystallinity, whiteness, mechanical strength, melt viscosity, oxygen index, polydispersity coefficient are more excellent.

[0048] 1. Synthesis example of polyphenylene sulfide resin containing aromatic heterocycle

example 1

[0050]In the autoclave, 120 kilograms of N-methyl-2 pyrrolidone (NMP) is a solvent, 42 kilograms of sodium sulfide (Na2S.3H2O) is added, 0.1 kilogram of lithium aluminum hydride (auxiliary agent), under the pressure of 0.01Mpa nitrogen, while Stir, while raising the temperature, take 2 hours to rise to 203 ° C for dehydration, add 24.9 kg of p-dichlorobenzene, 20 kg of NMP, and react at a temperature of 200 ° C for 3 hours, then add 29.9 kg of 2-(4-chlorophenyl )-5-chlorobenzimidazole (abbreviated as DCPBI), so that the mol ratio of sodium sulfide to p-dichlorobenzene and 2-(4-chlorophenyl)-5-chlorobenzimidazole is 1: 0.6: 0.4. When the temperature is 280°C, react for 4 hours, and under the condition of this temperature, add 0.36 kg of p-aminochlorobenzene, cool to 185°C after 2 hours of polymerization reaction, add 0.46 kg of terephthalic acid and heat up to 250°C for treatment After 1 hour, cool to 200°C, add 0.08 kg of deionizing agent mixture ethylenediaminetetraacetic ac...

example 2

[0052] In the autoclave, add 60 kilograms of N-methyl-2 pyrrolidone (NMP), 21.5 kilograms of sodium sulfide (Na2S.3H2O), 0.05 kilograms of lithium aluminum hydride (auxiliary agent), and stir under the pressure of 0.01Mpa nitrogen, While raising the temperature, take 8 hours to rise to 190°C for dehydration, add 18.3 kg of p-dichlorobenzene, 10 kg of NMP, and react at a temperature of 280°C for 1 hour, then add 3.75 kg of 2-(4-chlorophenyl)- 5-chlorobenzimidazole, like this, the molar ratio of sodium sulfide to p-dichlorobenzene and 2-(4-chlorophenyl)-5-chlorobenzimidazole is 1:0.9:0.1. When the temperature is 280°C, react for 6 hours, and under the condition of this temperature, add 0.89 kg of p-aminochlorobenzene, cool to 185°C after 2 hours of polymerization, add 0.75 kg of terephthalic acid and heat up to 250°C for treatment After 1 hour, cool to 100°C, add 0.54 kg of deionizing agent mixture ethylenediaminetetraacetic acid, and keep stirring for 1 hour, filter at 100°C an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com