Photothermal dual-curing solder resist ink with high adhesion and use method thereof

A technology of solder resist ink and high adhesion, applied in ink, photosensitive materials used in optomechanical equipment, optics, etc., can solve problems such as poor adhesion, difficulty, and decreased insulation reliability of solder resist ink coating, and achieve The effect of good adhesion and excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with specific embodiments.

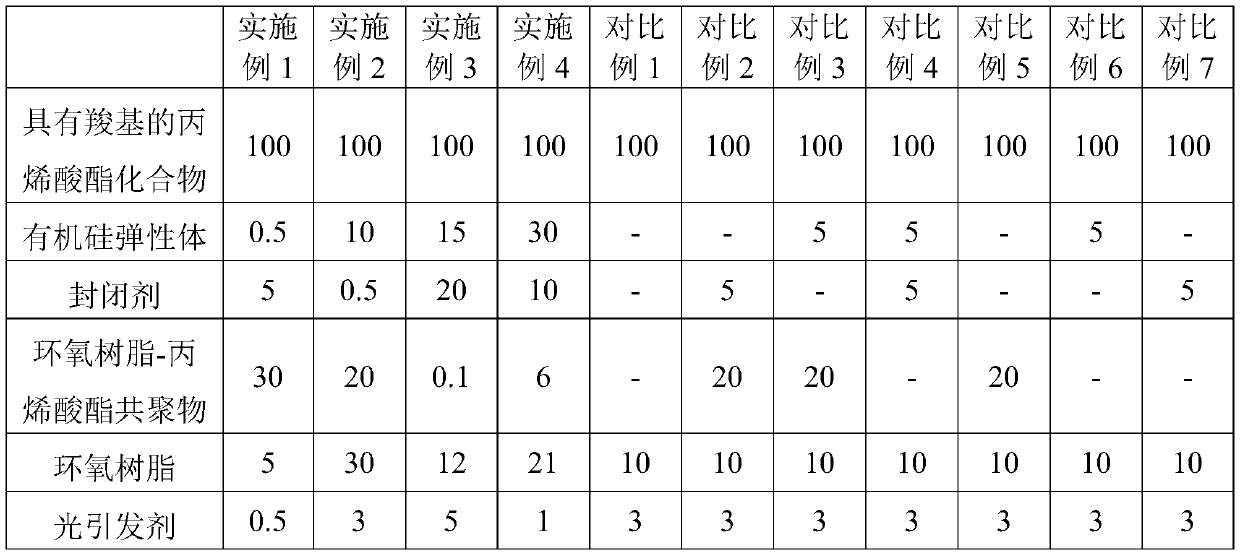

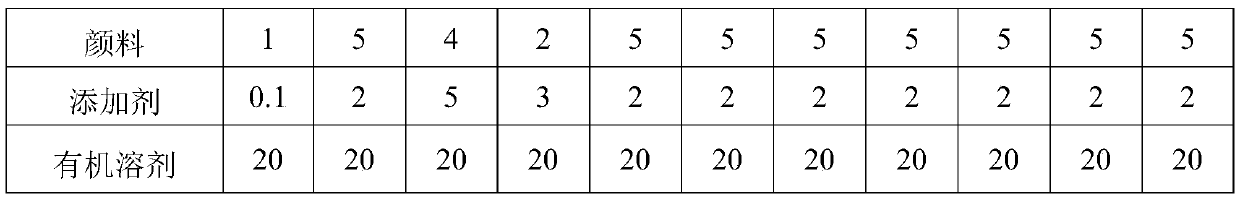

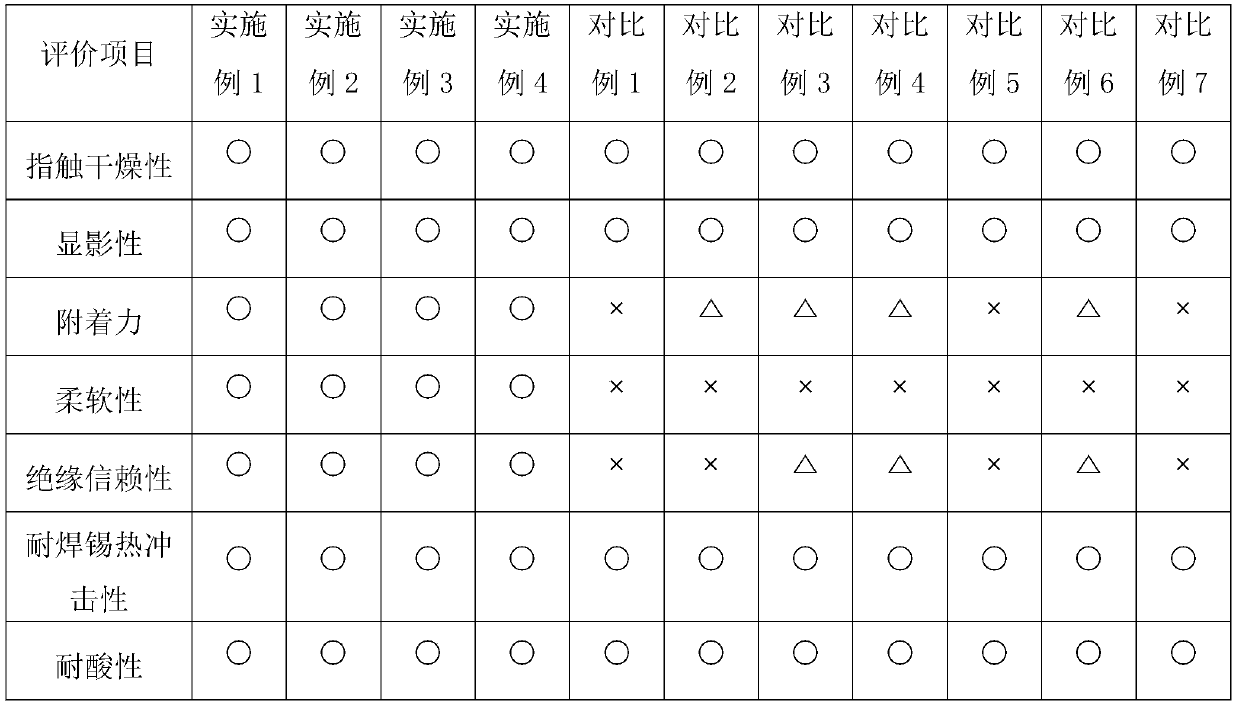

[0023] In a dust-free laboratory, the raw materials were stirred and mixed according to the proportions in Table 1 to prepare the photothermal dual-curing solder resist inks of Examples 1-4 and Comparative Examples 1-7.

[0024] Table 1:

[0025]

[0026]

[0027] Wherein the acrylate compound with carboxyl used in the embodiment refers to omega-carboxyl-polycaprolactone-acrylate; Silicone elastomer is the copolymerization compound of linear polysiloxane and elastic block and strengthening agent composition The complex body, the elastic block is polymethyl methacrylate block, the reinforcing agent is silica, quartz and diatomaceous earth; the sealing agent is methyl isocyanate; the epoxy resin-acrylate copolymer is bisphenol A Copolymer synthesized with acrylate; photoinitiator is benzoin; pigment is carbon black; additive is silicone leveling agent; organi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com