Preparation method of Nb roughening titanium aluminum base alloy composite material

A composite material and base alloy technology, applied in the field of powder metallurgy materials, can solve the problems of reducing the toughness of titanium-aluminum-based alloy materials, complex preparation process of AlC particles, and increasing the preparation cost of composite materials, so as to reduce deformation resistance and be difficult to stress concentration. , Uniform effect of plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

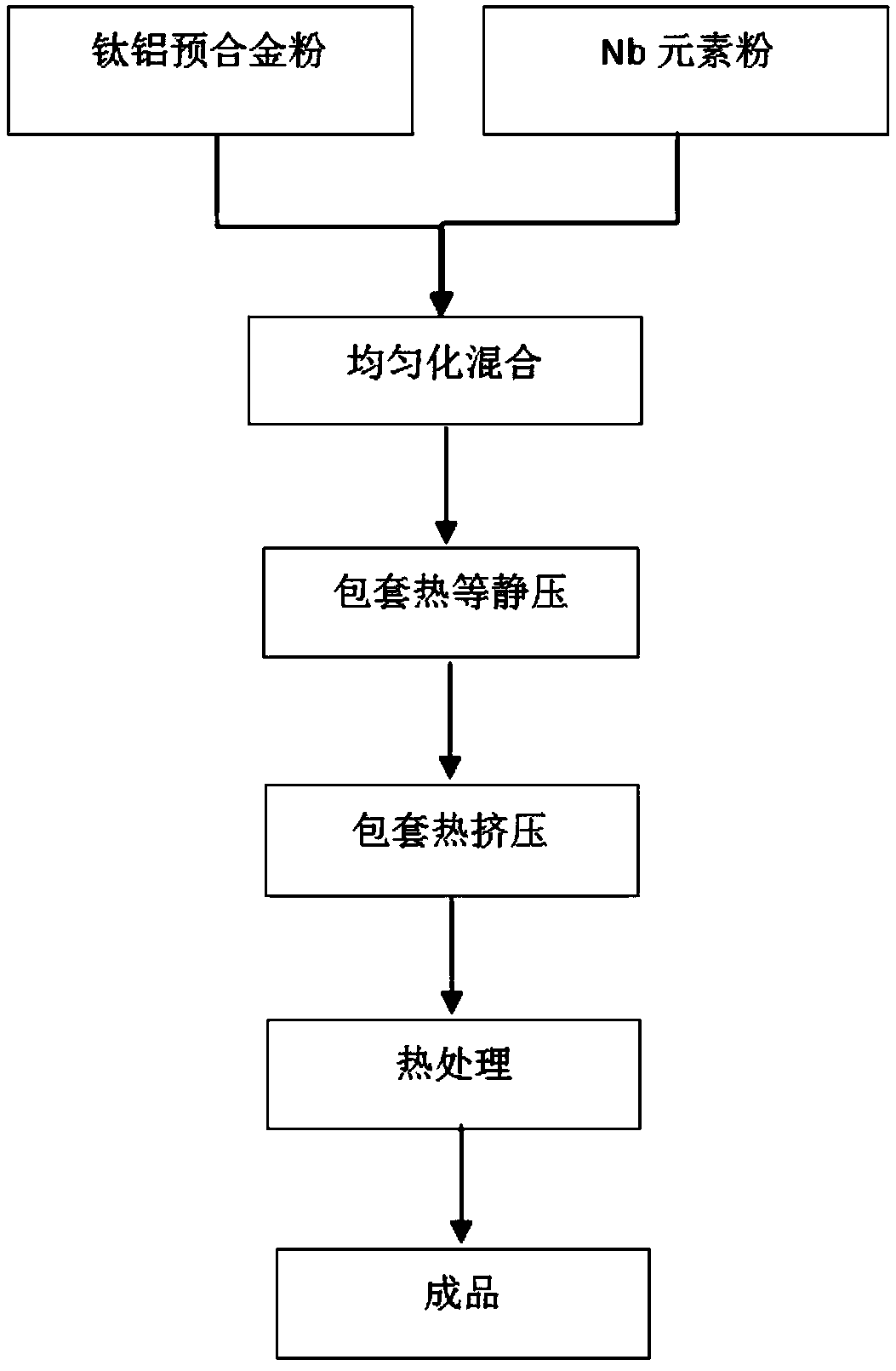

[0036] Such as figure 1 Shown, a kind of preparation method of titanium-aluminum matrix composite rod, comprises the following steps:

[0037] (1) With a particle size of -100 mesh titanium-aluminum pre-alloy powder (oxygen content is 0.47%) and a particle size of -150 mesh Nb powder (oxygen content is 0.34%) as raw materials, the above-mentioned titanium-aluminum pre-alloy powder is mixed with a V-shaped mixer The alloy powder and Nb powder were mixed for 8 hours, and the mixing process was always protected by argon; among them, the atomic ratio content of each element in the titanium-aluminum pre-alloy powder: Al: 45%, Nb: 7%, W: 0.4%, and the rest is Ti , the volume ratio content of Nb powder is 2% of the total amount of titanium-aluminum pre-alloyed powder and Nb powder;

[0038] (2) Put the mixed powder in step (1) into a cylindrical stainless steel sheath, the stainless steel sheath size is φ60×150mm (that is, the inner diameter d is 60mm, h is 150mm, the same below), a...

Embodiment 2

[0049] Such as figure 1 Shown, a kind of preparation method of titanium-aluminum matrix composite rod, comprises the following steps:

[0050] (1) With a particle size of -50 mesh titanium-aluminum pre-alloyed powder (oxygen content is 0.47%) and a particle size of -150 mesh Nb powder (oxygen content is 0.34%) as raw materials, the above-mentioned titanium-aluminum pre-alloy powder is mixed with a V-shaped mixer The alloy powder and Nb powder were mixed for 8 hours, and the mixing process was always protected by argon; among them, the atomic ratio content of each element in the titanium-aluminum pre-alloyed powder: Al: 45%, Nb: 5%, W: 0.4%, and the rest was Ti , the volume ratio content of Nb powder is 4% of the total amount of titanium-aluminum pre-alloyed powder and Nb powder;

[0051] (2) Put the powder mixed in step (1) into a cylindrical stainless steel sheath with a size of φ60×150mm, seal it with a stainless steel end cap and vacuum weld it, and then start hot isostati...

Embodiment 3

[0055] Such as figure 1 Shown, a kind of preparation method of titanium-aluminum matrix composite rod, comprises the following steps:

[0056] (1) With a particle size of -50 mesh titanium-aluminum pre-alloyed powder (oxygen content is 0.47%) and a particle size of -150 mesh Nb powder (oxygen content is 0.34%) as raw materials, the above-mentioned titanium-aluminum pre-alloy powder is mixed with a V-shaped mixer The alloy powder and Nb powder were mixed for 8 hours, and the mixing process was always protected by argon; among them, the atomic ratio content of each element in the titanium-aluminum pre-alloyed powder: Al: 45%, Nb: 5%, W: 0.4%, and the rest was Ti , the volume ratio content of Nb powder is 4% of the total amount of titanium-aluminum pre-alloyed powder and Nb powder;

[0057] (2) Put the mixed powder in step (1) into a cylindrical stainless steel sheath, the stainless steel sheath size is φ60×150mm (that is, the inner diameter d is 60mm, h is 150mm, the same below...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com