Method and device for processing malodorous gas by active bamboo charcoal-H2O2 complex phase catalytic oxidation

A multi-phase catalytic oxidation bed, malodorous gas technology, applied in the direction of chemical instruments and methods, catalyst regeneration/reactivation, combined devices, etc., can solve the problems of increasing device materials and volume, large ozone, large floor area, etc. Achieve the effect of good mechanical strength, not easy to break, and small air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

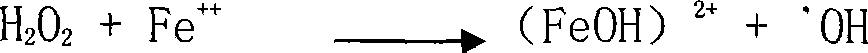

[0049] The preparation of embodiment 1 multiphase bamboo carbon catalyst

[0050] Raw material: hollow cylindrical bamboo, diameter Φ30mm-Φ50mm, length 30mm-50mm

[0051] Method: The composite bamboo carbon catalyst was prepared according to the following methods

[0052] 1. Bamboo charcoal is prepared by immersing the bamboo charcoal in a 0.8% by weight aqueous solution of ferrous sulfate with a pH of 2 for 2 hours, removing it and drying it in the air, and then drying it at a temperature of 100-300°C.

[0053] 2. Bamboo charcoal is prepared by immersing the bamboo charcoal in 0.1% by weight ferric sulfate aqueous solution with a pH of 3 for 2 hours, taking it out and drying it in the air, and then drying it at a temperature of 100-300°C.

[0054] 3. Bamboo charcoal is prepared by immersing the bamboo charcoal in a 1% by weight aqueous solution of ferrous sulfate with a pH of 5 for 2 hours, taking it out and drying it in the air, and then drying it at a temperature of 100-30...

Embodiment 2

[0058] Embodiment 2 activated bamboo carbon—H 2 o 2 Device for treatment of malodorous gas by multi-phase catalytic oxidation

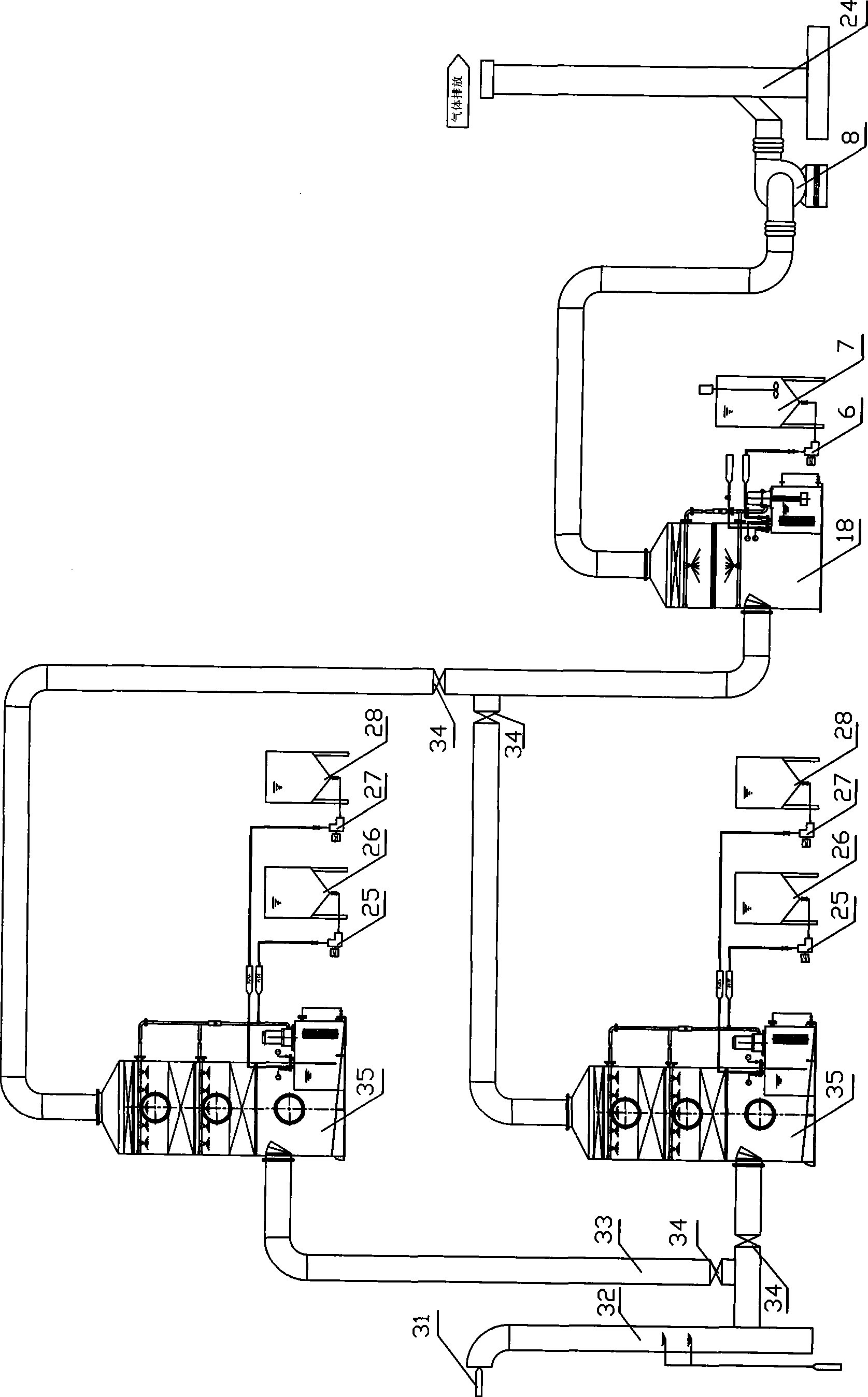

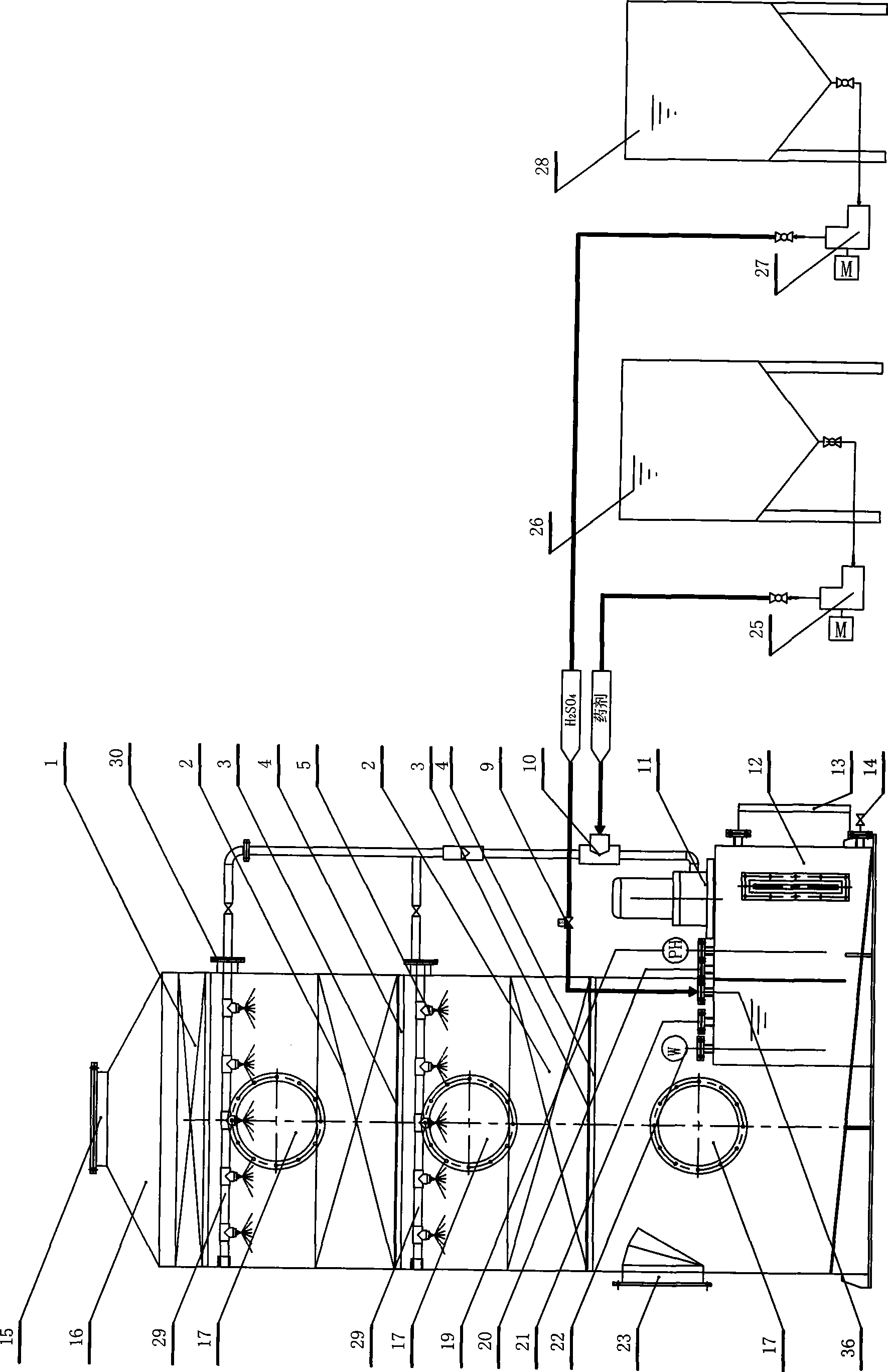

[0059] Such as figure 1 Activated bamboo carbon shown—H 2 o 2 The device for treating malodorous gas by multi-phase catalytic oxidation includes exhaust gas inlet 31, preprocessor 32, two parallel wet bamboo carbon multi-phase catalytic oxidation beds 35, alkali spray tower 18, blower fan 8 and exhaust gas Barrel 24.

[0060] The preprocessor 32 is an aerosol dust collector. The alkali spray tower 18 is a vertical structure, connected behind the wet-type bamboo-carbon multi-phase catalytic oxidation bed, the weakly acidic gas produced after the treatment of the wet-type bamboo-carbon multi-phase catalytic oxidation bed is carried out to neutralize the chemical reaction, so that the purified gas discharged is in the form of Neutral, meeting the requirements of national emission standards. The neutralization solution is a NaOH aqueous solution wi...

Embodiment 3

[0075] Example 3 Malodorous gas treatment

[0076] A certain spice company produces the malodorous gas in the production of granular spice products, adopts the active bamboo carbon-H of embodiment 2 2 o 2 Multi-phase catalytic oxidation device treatment of malodorous gas. Exhaust gas enters through exhaust gas inlet 31, and through preprocessor 32, enters wet-type bamboo-carbon composite-phase catalytic oxidation bed 35 by exhaust-gas inlet 23, and in wet-type bamboo-carbon composite-phase catalytic oxidation bed, first passes through composite-phase bamboo-carbon catalyst 2 to absorb To remove odorous substance molecules, the aqueous solution of hydrogen peroxide is sprayed onto the multiphase bamboo carbon catalyst 2 through the nozzle 5 to decompose the adsorbed odorous substance molecules and achieve the recycling of the multiphase bamboo carbon catalyst, and the gas goes up to the mist eliminator 1 after water and gas separation , discharged from the purified gas outlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com