Biomimetic structure type polymer actuator and preparation method thereof

A polymer and actuator technology, applied in the direction of liquid chemical plating, coating, non-woven fabrics, etc., can solve the problems that the structure does not realize bionics, increase the cost of IPMC, and unfavorable the promotion and application of IPMC, and achieve excellent mechanical strength, The effect of good conductivity and good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

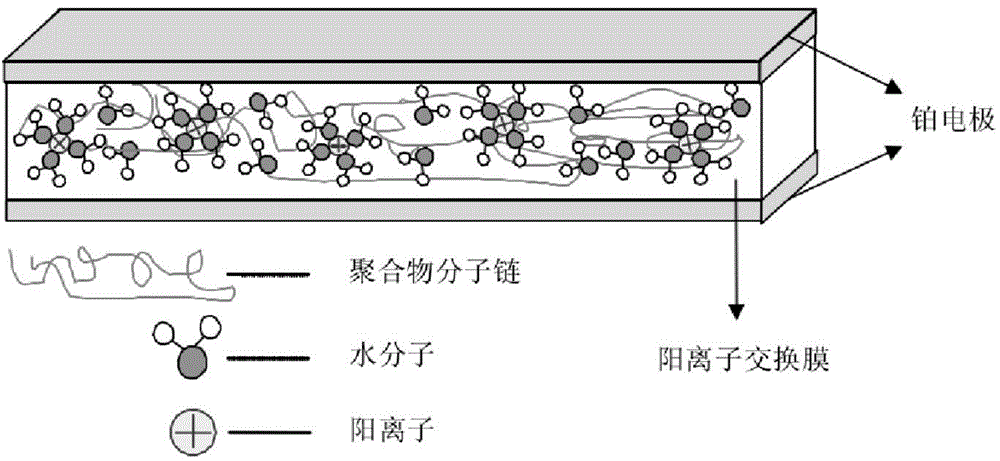

[0052] see figure 1 , the bionic polymer actuator of the present invention is mainly composed of a layer of polymer film and platinum electrodes covering both sides of the polymer film, wherein the polymer film is the sulfonated block copolymer (SPTES)-Nafion hybrid film.

[0053] 1. Preparation of sulfonated block copolymer (SPTES)-Nafion hybrid film:

[0054] 1) Synthesis of sulfonated monomer (SDFDPS):

[0055] Dissolve 25.4g of difluorodiphenyl sulfone in 50mL of oleum with a volume fraction of 50%, and stir and react at 160°C for 12h. After the reaction, adjust the pH value of the reaction solution to 6 with 4mol / L NaOH solution, and add 120g Nacl, stirred and reacted in an ice-water bath until sulfonated monomer crystals formed, dissolved sulfonated monomer crystals in a mixed solution of 80% (v / v) isopropanol and deionized water, purified at 80°C to produce white crystals , filter the purified white crystals, and dry them in vacuum at 100°C for 24 hours to obtain sul...

Embodiment 2

[0086] 1. Preparation of sulfonated block copolymer (SPTES)-Nafion hybrid film:

[0087] 1) Synthesis of sulfonated monomer (SDFDPS): the volume of oleum with a volume fraction of 50% is 53mL, stirred and reacted at 165°C for 13h, adjusted the pH value to 7, added 123g NaCl, and the obtained sulfonated monomer crystals were dissolved In 83% (v / v) isopropanol and deionized water mixed solution, purified at 85°C, and vacuum dried at 103°C after purification, other conditions were the same as in Example 1.

[0088] 2) Synthesis of sulfonated block copolymer (SPTES):

[0089] ①Synthesis of non-sulfonated copolymer block A: add 110mL dimethylacetamide, stir for 1.5h, heat up to 103°C and stir for 1.5h, then add 43mL toluene, stir for 2.5h at 123°C, heat up to React at 145°C for another 2.5h, then raise the temperature to 163°C for 3.5h, precipitate the copolymer with a mixture of 2:1 (v / v) methanol and deionized water, and extract it with methanol for 50h, then at 85°C Under vacu...

Embodiment 3

[0106] 1. Preparation of sulfonated block copolymer (SPTES)-Nafion hybrid film:

[0107] 1) Synthesis of sulfonated monomer (SDFDPS): the volume of oleum with a volume fraction of 50% is 55mL, stirred and reacted at 170°C for 14h, adjusted the pH value to 7, added 125g NaCl, and the obtained sulfonated monomer crystallized It was dissolved in a mixed solution of 85% (v / v) isopropanol and deionized water, purified at 90° C., and vacuum-dried at 105° C. after purification. Other conditions were the same as in Example 1.

[0108] 2) Synthesis of sulfonated block copolymer (SPTES):

[0109] ① Synthesis of non-sulfonated copolymer block A: add 120mL dimethylacetamide, stir for 2h, heat up to 105°C and stir for 2h, then add 45mL toluene, stir for 3h at 125°C, heat up to 150°C and then React for 3 hours, then raise the temperature to 165° C. for 4 hours, extract with methanol for 52 hours, and then vacuum dry at 90° C. for 26 hours. Other conditions are the same as in Example 1.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com