Magnetic polyacrylamide/zirconium alginate gel beads as well as preparation method and application thereof

A technology of zirconium alginate gel balls and polyacrylamide, which is applied in chemical instruments and methods, magnetic/electric field water/sewage treatment, and other chemical processes, and can solve poor adsorption capacity and stability, difficult separation and recovery, and phosphorus resources. Recycling and other issues, to achieve the effect of improving adsorption performance, low price, and high adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

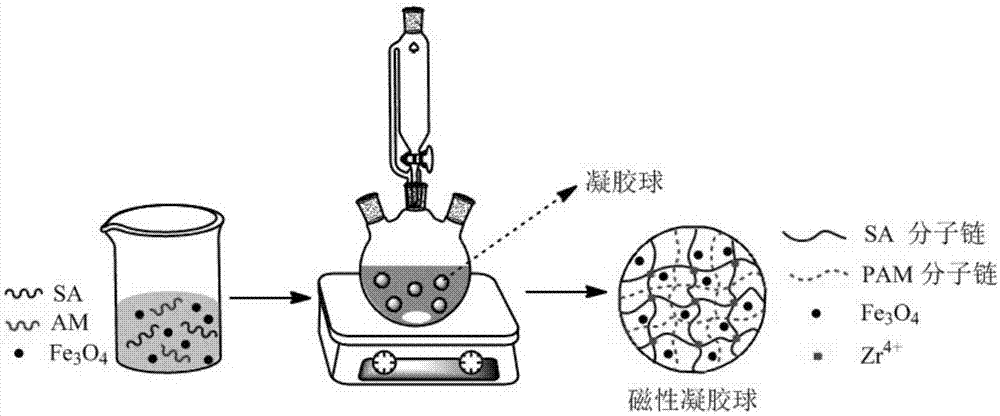

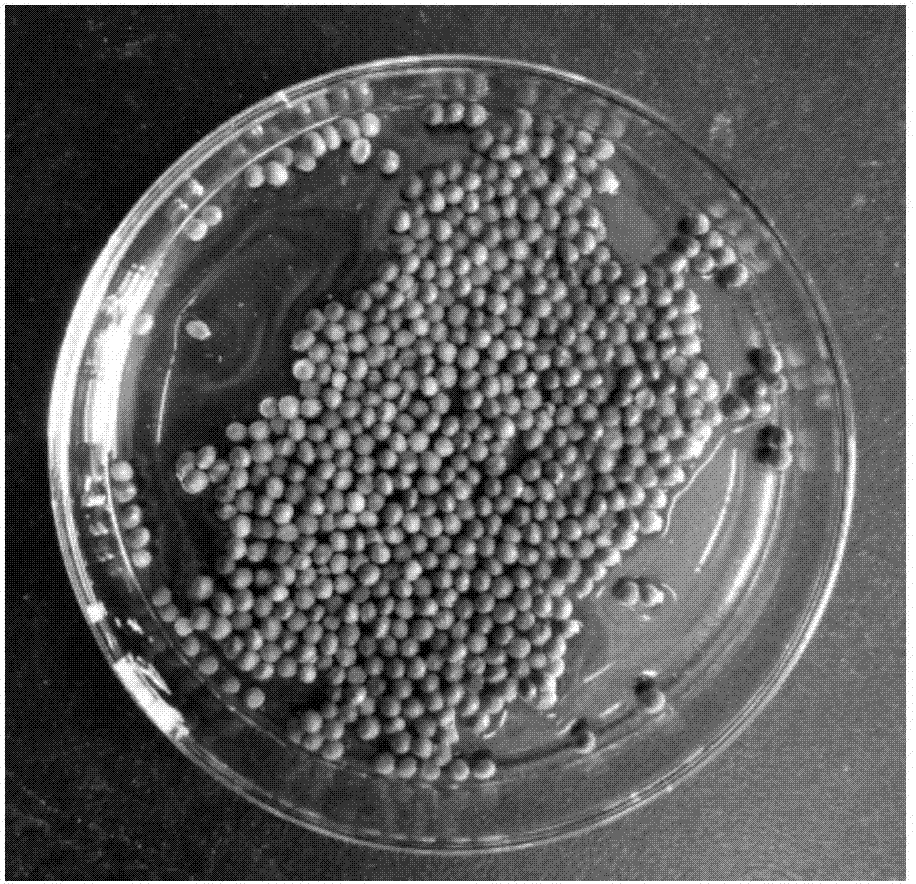

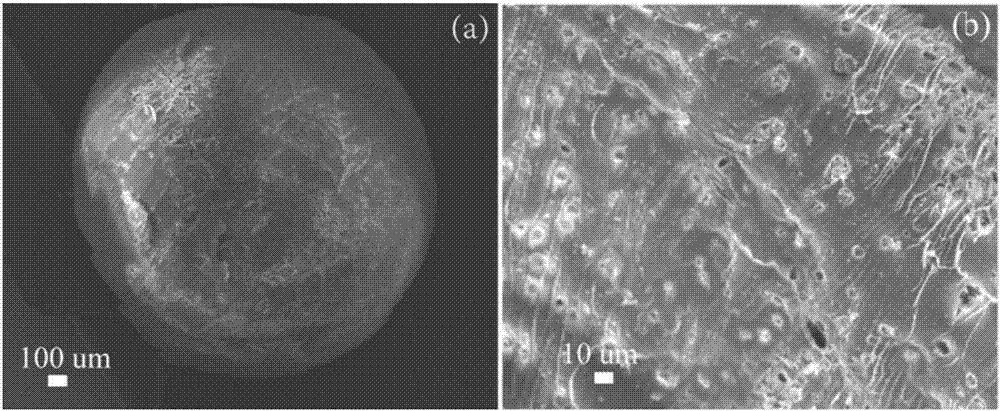

[0034] Magnetic polyacrylamide / zirconium alginate (Fe 3 o 4 Preparation method and characterization results of @PAM / SA-Zr) gel ball adsorbent

[0035] Step (1): Weigh 0.42g FeCl 3 ·6H 2 O and 0.218g FeSO 4 ·7H 2 O was dissolved in 300mL deionized water, placed in a four-neck flask, N 2 After stirring mechanically for 30min under protection, add 600μL 10mol / L NaOH solution, 2 Stirring was continued for 1 hour under protection; at the same time, the water temperature was rapidly raised to 90°C, and 300 mL of sodium citrate solution (0.3 mol / L) was started to be added dropwise. More than three times, and finally re-disperse the obtained product in deionized water, ultrasonically form a stable nano-magnetic fluid, and set the volume to 50mL.

[0036] Step (2): Dissolve 1 g of sodium alginate in the magnetic fluid solution of step (1) at room temperature, stir at 450 rpm for 6 h until uniform, then add 3.84 g of acrylamide, 0.4164 g of N,N'-methylene Base bisacrylamide and ...

Embodiment 2

[0042] Contact time vs. Fe 3 o 4 Study on the influence of @PAM / SA-Zr on the adsorption performance of phosphate in water

[0043] In the present invention, the prepared magnetic Fe 3 o 4 @PAM / SA-Zr gel spheres were used in the adsorption of phosphate in water to investigate the effect of contact time on Fe 3 o 4 Effect of @PAM / SA-Zr adsorption performance. Ammonium molybdate spectrophotometry is used to measure the concentration of phosphate in water before and after adsorption, and its adsorption capacity is calculated respectively with formula (1):

[0044]

[0045] Among them, q t is the average adsorption capacity per unit mass of adsorbent within t time, mg-P / g; C o is the concentration of phosphate in the solution before adsorption, mg / L; C t is the concentration of phosphate in the solution after the adsorption time t, mg / L; V is the volume of the phosphate solution, L; m is the mass of the adsorbent, g.

[0046] The experimental conditions for the influenc...

Embodiment 3

[0048] Fe 3 o 4 Adsorption study of @PAM / SA-Zr for different initial concentrations of phosphate in water

[0049] Prepare different concentrations of phosphate solutions (10, 25, 50, 75, 100, 125, 150mg / L), adjust the pH of the solution=2, get each 20mL of the above-mentioned solutions of different concentrations, add the Fe prepared by the above-mentioned implementation cases 3 o 4 Each 0.05g of @PAM / SA-Zr gel balls was taken out after constant temperature shaking at 25°C for 30 hours, and the adsorption capacity was determined according to the formula (1). The calculation results are shown in Image 6 . It can be seen that the adsorption capacity of the prepared gel spheres increases with the increase of the initial phosphate concentration, which may be due to the increase of the phosphate concentration in the system, which increases the coordination probability of the phosphate radical and the binding site of the adsorbent. leading to an improvement in adsorption perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com