Fracturing ceramsite proppant produced by steel slag and preparation method thereof

A technology of proppant and steel slag, which is applied in the direction of chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problems of high product density, high cost, and large energy consumption, achieve high mechanical strength, reduce occupation effects of land and pollution on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below:

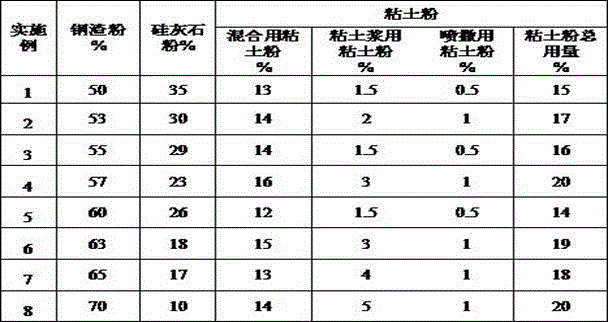

[0033] Table 1 is a list of raw material values in each embodiment of the present invention;

[0034] Table 2 is the value list of the main process parameters of each embodiment of the present invention;

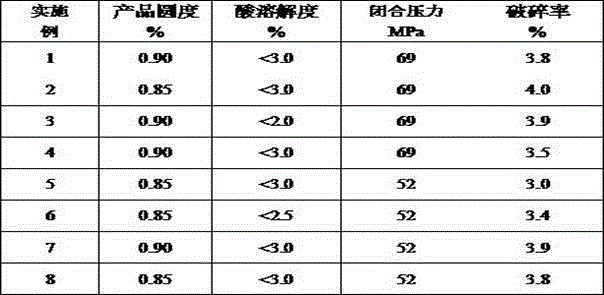

[0035] Table 3 is a list of performance test results of various embodiments of the present invention.

[0036] Each embodiment of the present invention is produced according to the following steps:

[0037] 1) Fully mix steel slag with a particle size of ≤75 microns, wollastonite with a particle size of ≤75 microns, and clay with a particle size of ≤45 microns except for the amount used as clay slurry and sprayed in the preparation of pellets;

[0038] 2) Input the mixed material into the ball making machine, and control the running speed of the ball making machine at 15-60 rpm; during this period, spray the adjusted clay slurry on the surface of the mixed material, and spray on the surface after the pellet mak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com