Wood-grain pottery glaze, wood-grain pottery product prepared by same, and process

A technology of ceramic products and ceramic glaze, applied in the field of ceramics, can solve the problems of cumbersome and complicated process, uncontrollable lead and cadmium, long production cycle, etc., achieve obvious effect of wood grade, solve the problem of excessive dissolution of lead and cadmium, and improve the yield of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

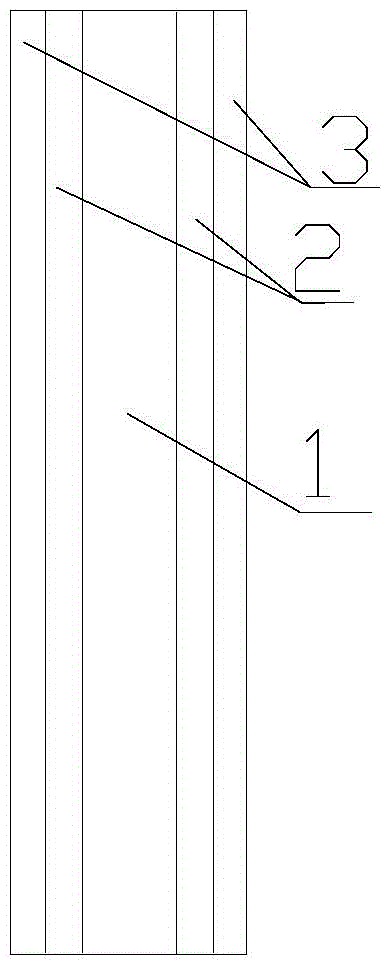

Image

Examples

Embodiment 1

[0037] The wood grain ceramic glaze of the present invention comprises the following components by weight:

[0038] Bottom glaze: 44% potassium feldspar, 4% No. 1 frit, 20% barium carbonate, 5% limestone, 5% calcined talc, 10% Longyan kaolin, 10% titanium oxide, and 2% vanadium yellow. Among them, No. 1 frit includes the following components in parts by weight: 38% albite, 12% quartz, 25% boron ore, 5% kaolin, and 20% calcium carbonate.

[0039] Surface glaze: potassium feldspar 30%, No. 2 frit 41.8%, wollastonite 12%, Longyan kaolin 5%, pigment 11%, carboxymethyl cellulose 0.2%. Among them, No. 2 frit includes the following components by weight: 39% boron ore, 15% quartz, 32% albite, 6% kaolin, and 8% calcium carbonate.

[0040] Utilize above-mentioned glaze material to prepare the technique of wood grain ceramic product as:

[0041] Grinding: Put the bottom glaze and top glaze into the ball mill, and then add water with 77~82% of the weight of the raw materials for normal ...

Embodiment 2

[0048] The wood grain ceramic glaze of the present invention comprises the following components by weight:

[0049] Bottom glaze: potassium feldspar 47%, No. 1 frit 4%, barium carbonate 19%, limestone 4%, calcined talc 4%, Longyan kaolin 10%, titanium oxide 11%, vanadium yellow 1%. Among them, No. 1 frit includes the following components in parts by weight: 37% albite, 12% quartz, 24% boron ore, 6% kaolin, and 21% calcium carbonate.

[0050] Surface glaze: potassium feldspar 28%, No. 2 frit 42.7%, wollastonite 13%, Longyan kaolin 6%, pigment 10%, carboxymethyl cellulose 0.3%. Wherein, No. 2 frit includes the following components by weight: 40% boron ore, 16% quartz, 31% albite, 4% kaolin, and 9% calcium carbonate.

[0051] Utilize above-mentioned glaze material to prepare the technique of wood grain ceramic product as:

[0052] Grinding: Put the bottom glaze and top glaze into the ball mill, and then add water with 77~82% of the weight of the raw materials for normal ball mi...

Embodiment 3

[0059] The wood grain ceramic glaze of the present invention comprises the following components by weight:

[0060] Bottom glaze: 43% potassium feldspar, 5% No. 1 frit, 21% barium carbonate, 6% limestone, 6% calcined talc, 9% Longyan kaolin, 9% titanium oxide, and 1% vanadium yellow. Among them, No. 1 frit includes the following components in parts by weight: 38% albite, 11% quartz, 26% boron ore, 6% kaolin, and 19% calcium carbonate.

[0061] Surface glaze: potassium feldspar 32%, No. 2 frit 39.9%, wollastonite 11%, Longyan kaolin 5%, pigment 12%, carboxymethyl cellulose 0.1%. Among them, No. 2 frit includes the following components by weight: 38% boron ore, 16% quartz, 33% albite, 5% kaolin, and 8% calcium carbonate.

[0062] Utilize above-mentioned glaze material to prepare the technique of wood grain ceramic product as:

[0063] Grinding: Put the bottom glaze and top glaze into the ball mill, and then add water with 77~82% of the weight of the raw materials for normal ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com