Selective ammonium removal material and preparation method and application thereof

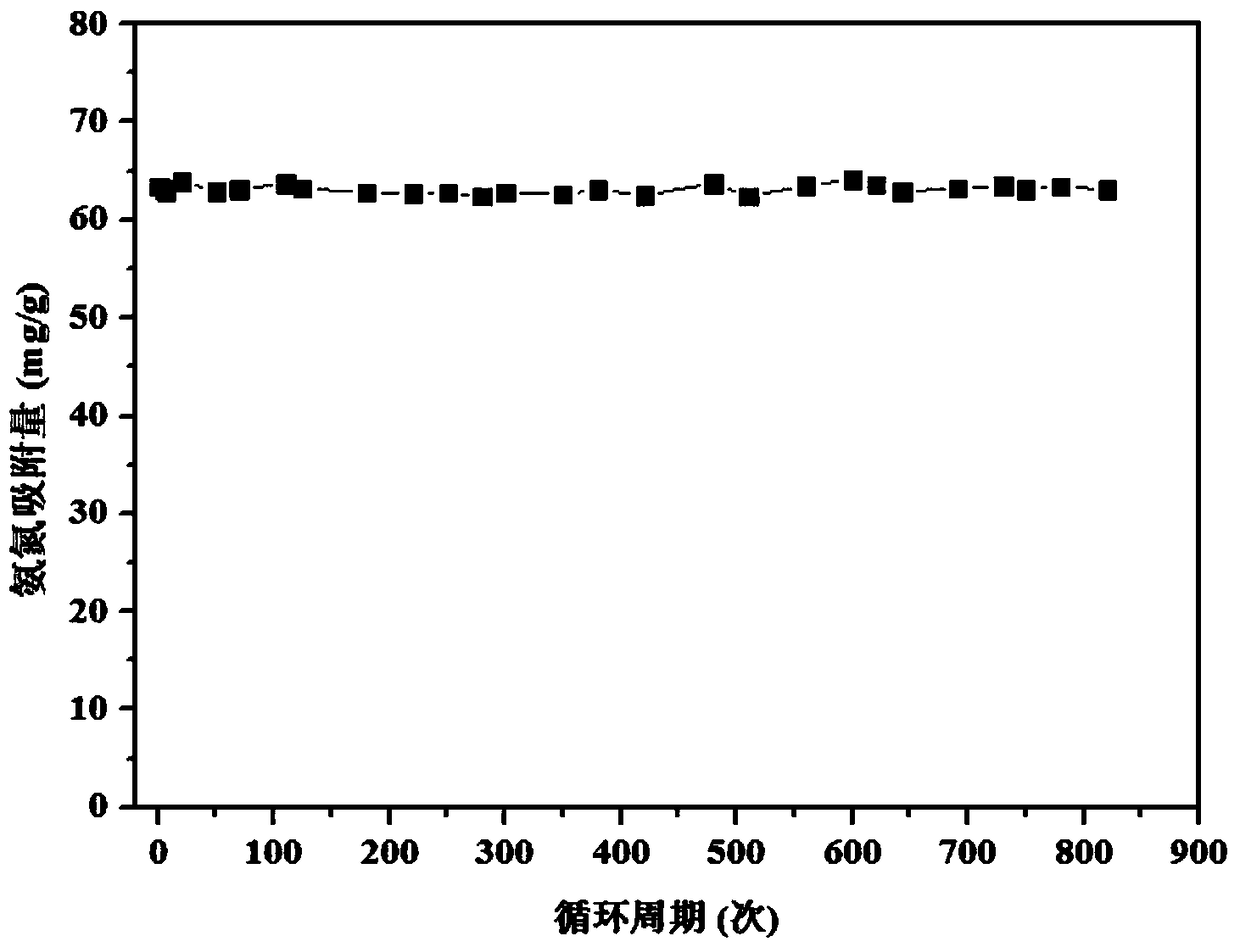

A selective and deammonium technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc. Environmental protection, easy industrial scale-up, stable material structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

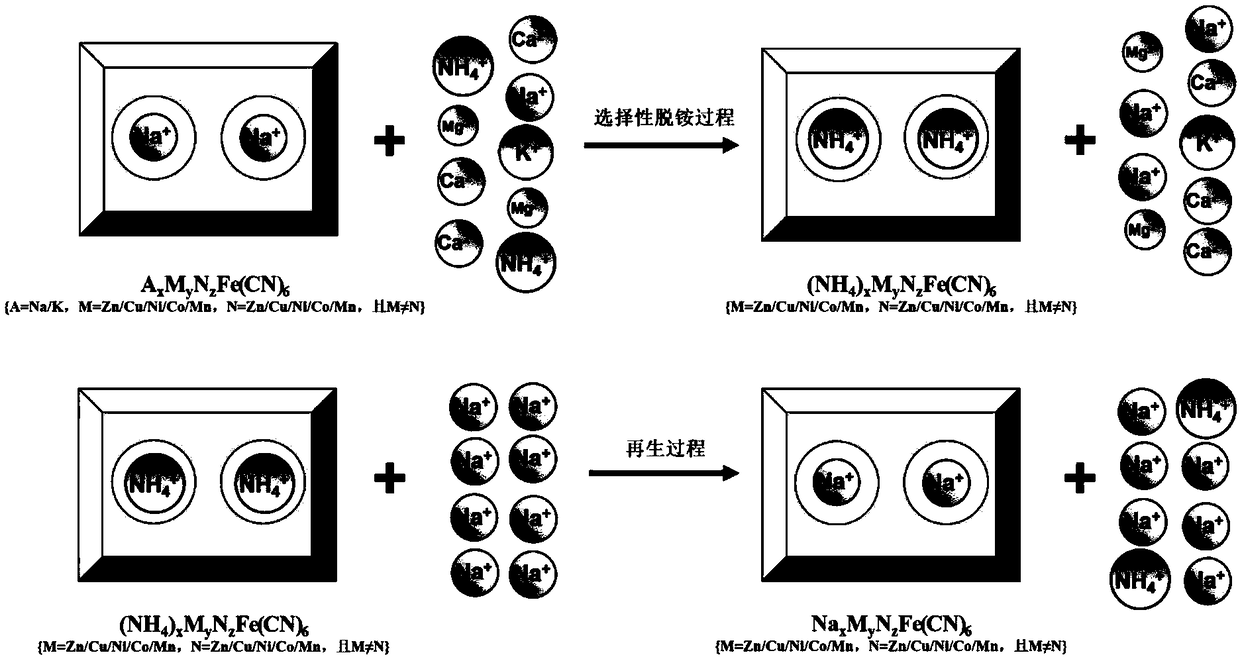

[0027] The invention provides a kind of preparation method of selective deammonization material, comprises the following steps:

[0028] (1) Sodium ferrocyanide or potassium ferrocyanide and two kinds of transition metal salts are mixed with water respectively into corresponding sodium ferrocyanide or potassium ferrocyanide solution and two kinds of transition metal salt solutions;

[0029] (2) Under stirring conditions, sodium ferrocyanide or potassium ferrocyanide solution and two kinds of transition metal salt solutions are added dropwise to the receiving liquid at the same time, and aged to control the crystal shape to be spherical or cubic, and then Separation and cleaning;

[0030] (3) The cleaned material is dried to obtain powdery selective deammonization material A x m y N z [Fe(CN) 6 ] 2 , where A is Na or K, M and N are transition metal elements respectively, and M≠N, x, y, z satisfy the relationship: x+2y+2z=8, 0

[0031] The invention adop...

Embodiment 1

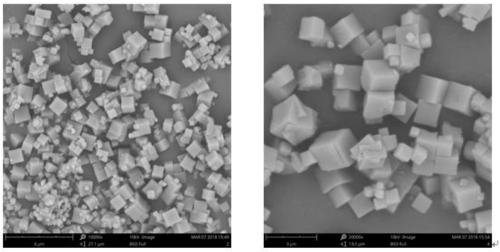

[0061] Example 1: Na 2 Zn 2 Cu[Fe(CN) 6 ] 2 preparation of

[0062] (1) Weigh 1 mol of sodium ferrocyanide, 2 mol of zinc sulfate and 1 mol of copper sulfate mixed solution into 1L of deionized water, respectively, to prepare 1 mol / L of sodium ferrocyanide solution, 2 mol / L of zinc sulfate and 1 mol / L of copper sulfate. L copper sulfate mixed solution;

[0063] (2) At the speed of 500rpm, add 1mol / L sodium ferrocyanide solution and 2mol / L zinc sulfate and 1mol / L copper sulfate mixed solution into 100mL pure water at the same time at a speed of 100ml / min, drop Keep magnetic stirring during the addition process, continue mixing and stirring for 2 hours after the addition is completed to obtain a reddish-brown turbid liquid, then age for 2 hours, and wash 5 times after centrifugation to obtain the selective deammonization material Na 2 Zn 2 Cu[Fe(CN) 6 ] 2 ;

[0064] (3) The selective deammonization material Na 2 Zn 2 Cu[Fe(CN) 6 ] 2 Place in a vacuum drying oven and...

Embodiment 2

[0065] Example 2: Na 2 CuCo 2 [Fe(CN) 6 ] 2 preparation of

[0066] (1) Weigh 0.5mol sodium ferrocyanide, 1mol copper sulfate and 0.5mol cobalt sulfate mixed solution, and 2mol sodium chloride and add them to 1L deionized water respectively to prepare 0.5mol / L sodium ferrocyanide solution, 1mol / L copper sulfate and 0.5mol / L cobalt sulfate mixed solution and 2mol / L sodium chloride solution;

[0067] (2) At a speed of 200rpm, add 0.5mol / L sodium ferrocyanide solution and 1mol / L copper sulfate and 0.5mol / L cobalt sulfate mixed solution to 100mL containing 2mol / L cobalt sulfate solution simultaneously at a speed of 100ml / min. In the sodium chloride solution of L, maintain magnetic stirring during the dropping process, continue mixing and stirring for 2 hours after the dropping is completed to obtain a reddish-brown turbid liquid, then age for 5 hours, and wash 6 times after centrifugation to obtain the selective deammonization material Na 2 CuCo 2 [Fe(CN) 6 ] 2 ;

[0068]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com