Direct-casting type anti-track agent and preparation method

An anti-rutting agent, direct investment technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of poor compatibility between modifier and asphalt, complex and time-consuming preparation process, uneconomical and environmental protection, etc. Good capacity, improved flow capacity and processing performance, and reduced segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

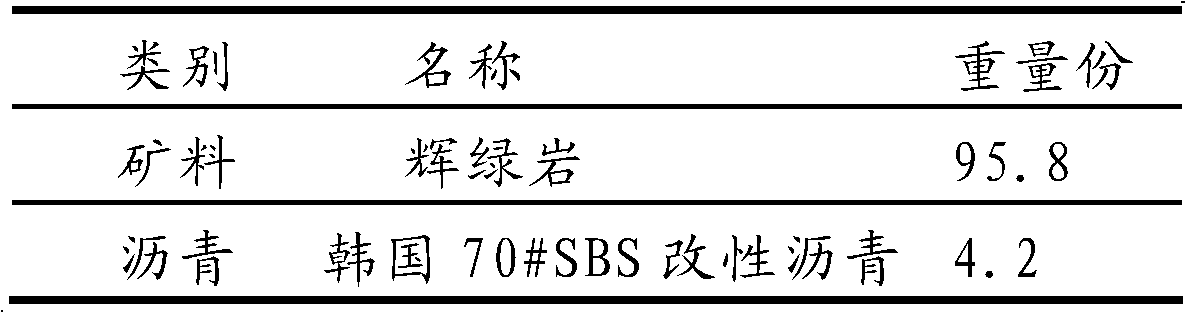

[0038] Weigh 40 parts of recycled low-density polyethylene by weight; 15 parts of recycled polymethyl acrylate; 2 parts of recycled polyethylene wax; 1 part of nano shell powder with a particle size range of 100 nm to 150 nm; and 10 parts of hard pitch.

[0039] First, at 150℃, stir and heat the hard asphalt at 5r / min for 15min;

[0040] Then add recycled low-density polyethylene, recycled polymethyl acrylate, recycled polyethylene wax and nano shell powder to the hot hard asphalt, stir at a speed of 5r / min for 5 minutes; after completing this step, put the mixture at 140°C Heat for 5 hours;

[0041] Next, stir the mixture for 50 minutes at a speed of 30r / min at 160°C;

[0042] Finally, a single-screw extruder is used for forming, shearing and pelletizing to prepare a direct throw anti-rutting agent.

Embodiment 2

[0044] Weigh 30 parts of recycled low-density polyvinyl chloride by weight; 15 parts of recycled ethylene-vinyl acetate copolymer; 3 parts of recycled polyethylene wax; 1 part of nano-hydroxyapatite powder with a particle size range of 50nm~150nm; 8 parts of hard asphalt; 0.02 parts of anti-stripping agent.

[0045] First, heat the hard asphalt with stirring at 4r / min for 10min at 160℃;

[0046] Then add recycled low-density polyvinyl chloride, recycled ethylene-vinyl acetate copolymer, recycled polyethylene wax and nano-hydroxyapatite powder to the hot hard asphalt, stir at 8r / min for 5min; after completing this step, Heat the mixture at 135°C for 4.5h;

[0047] Then add the anti-stripping agent to the mixture and stir for 4 minutes at a speed of 3r / min; then stir the mixture for 40 minutes at a speed of 25r / min at 170°C; this embodiment calculates the need to add according to the design method of the asphalt mixture Anti-stripping agent. The anti-stripping agent is a surfactant o...

Embodiment 3

[0050] Weigh 20 parts of recycled polypropylene by weight; 10 parts of recycled polyethyl acrylate; 4 parts of recycled polyvinyl chloride wax; 2 parts of nano shrimp shell powder with a particle size range of 50nm~150nm; 9 parts of hard pitch; anti-stripping Agent 0.03 parts.

[0051] First, at 170℃, stir and heat the hard asphalt at 3r / min for 8min;

[0052] Then add recycled polypropylene; recycled polyethyl acrylate; recycled polyvinyl chloride wax; nano shrimp shell powder to the hot hard asphalt; stir at 6r / min for 5min; after completing this step, put the mixture at 130°C Heating for 4h;

[0053] Then add the anti-stripping agent to the mixture, stir at 4r / min for 5min; then at 160℃, stir the mixture at 20r / min for 30min; this example needs to be added according to the design method of asphalt mixture Anti-stripping agent. The anti-stripping agent is a surfactant of amine compounds or phosphoric hydroxyl organic compounds; it is mainly used to increase the adhesion of asphal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com