Polymer cement waterproof coating and preparation method thereof

A waterproof coating and polymer technology, applied in the field of building materials, can solve the problem of not being able to quickly and accurately find leakage points, and achieve the effect of dense film formation, rapid and accurate identification, and improved waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

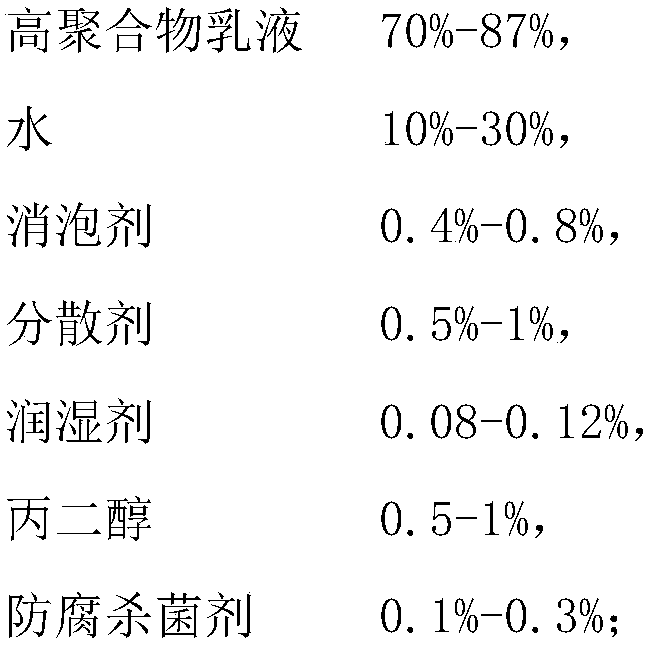

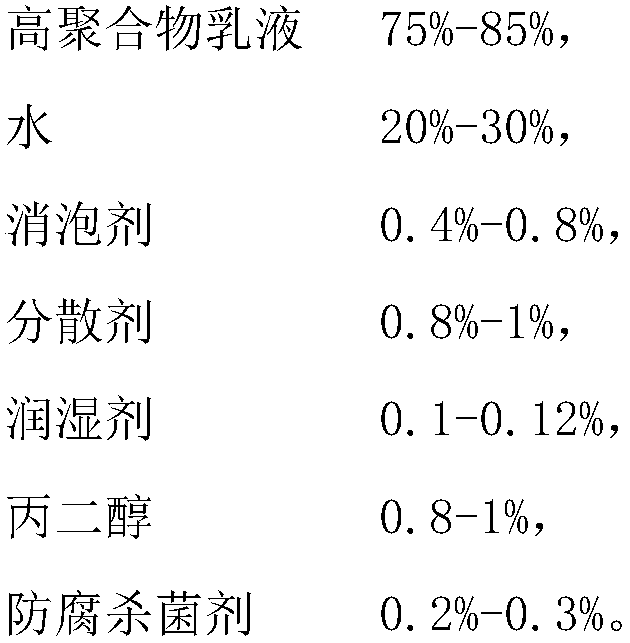

[0030] Prepare the raw materials according to the liquid material formula: 85g VAE emulsion, 15g water, 0.4g defoamer, 1g polyacrylate dispersant, 0.1g fluorocarbon, 1g propylene glycol, 0.2g isothiazolinone derivative; Add it to the disperser, vacuumize and stir for 30 minutes to obtain the liquid material;

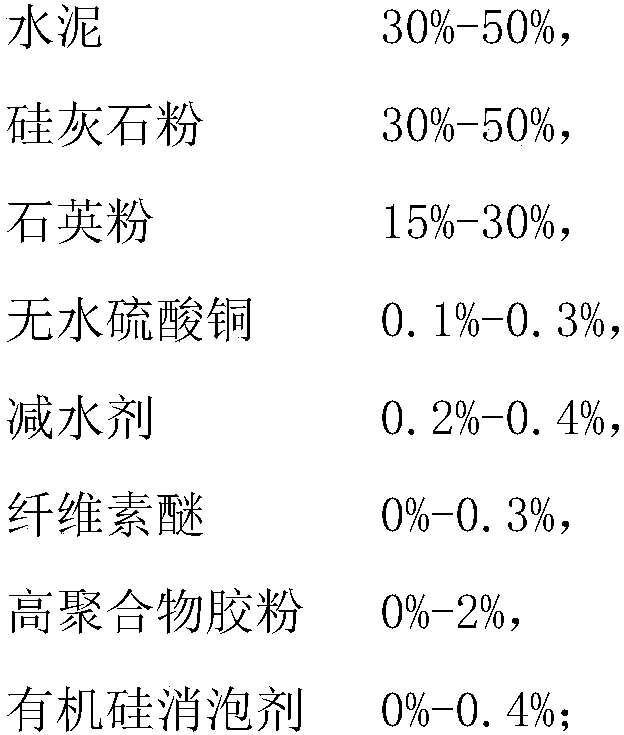

[0031] Prepare the raw materials according to the powder formula: 30g ordinary Portland cement, 50g wollastonite powder (1250 mesh), 20g quartz powder (1250 mesh), 0.1g anhydrous copper sulfate, 0.2g naphthalene-based water reducing agent; Add it to the mortar horizontal mixer in turn, and stir for 4 minutes to obtain the powder;

[0032] During construction and use, prepare the liquid material and the powder material according to the mass ratio of the liquid material and the powder material at a ratio of 10:8; pour the liquid material into the container first, (you can add liquid material according to the consistency and customary construction feel) The amount of water...

Embodiment 2

[0036] Prepare the raw materials according to the liquid material formula: 75g VAE emulsion, 24g water, 0.4g defoamer, 0.8g polyacrylate dispersant, 0.1g fluorocarbon, 1g propylene glycol, 0.2g benzimidazole esters; Add it to the disperser, vacuumize and stir for 30 minutes to obtain the liquid material;

[0037] Prepare the raw materials according to the powder formula: 40g early-strength Portland cement, 40g wollastonite powder (1250 mesh), 20g quartz powder (1250 mesh), 0.2g anhydrous copper sulfate, 0.3g naphthalene-based superplasticizer; The above-mentioned raw materials are sequentially added into a mortar horizontal mixer, and the powder is obtained after stirring for 4 minutes;

[0038] During construction and use, prepare the liquid material and the powder material according to the mass ratio of the liquid material and the powder material at a ratio of 10:12; pour the liquid material into the container first, (you can add liquid material according to the consistency ...

Embodiment 3

[0041] Prepare the raw materials according to the liquid material formula: 70g VAE emulsion, 28g water, 0.4g defoamer, 0.5g polyacrylate dispersant, 0.1g fluorocarbon, 1g propylene glycol, 0.2g1,2-benzisothiazoline-3- Ketone; the above-mentioned raw materials are sequentially added to the disperser, and the liquid material is obtained after vacuum stirring for 30 minutes;

[0042] Prepare each raw material according to the powder formula: 50g sulfate cement, 30g wollastonite powder (1250 mesh), 20g quartz powder (1250 mesh), 0.3g anhydrous copper sulfate, 0.3g naphthalene series superplasticizer; Add it to the mortar horizontal mixer in turn, and stir for 4 minutes to obtain the powder;

[0043] During construction and use, prepare the liquid material and the powder material according to the mass ratio of the liquid material and the powder material at a ratio of 10:15; pour the liquid material into the container first, (you can add liquid material according to the consistency ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com