High-hardness wollastonite glaze slip and preparation method thereof

A wollastonite and high-hardness technology is applied in the field of high-hardness wollastonite glaze slurry and its preparation, which can solve the problem that the glaze hardness cannot achieve a satisfactory effect, and achieve the improvement of scratching, fine glaze, The effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

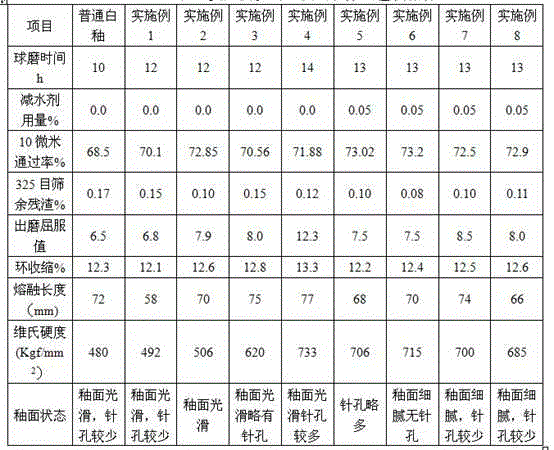

Embodiment 1

[0022] As shown in the formula list in Table 1, wollastonite is 5.83%, and its glaze mainly contains the following substances by weight: SiO 2 59.65%, Al 2 o 3 8.66%, Fe 2 o 3 0.15%, TiO 2 0.04%, CaO 9.48%, MgO 0.96%, K 2 O 3.18%, Na 2 O 1.37%, ZnO 3.47%, ZrO 2 6.72%, Lg.loss 5.99%, and the remaining 0.33% are impurities.

[0023] The preparation method is as follows: the raw materials are prepared according to the above components and the parts by weight of each component, according to ball: glaze: water = 1.5:4:3, wet ball milling for 12 hours, the glaze after ball milling requires a particle size of 10 microns and a passing rate of 70.1 %, 325 mesh sieve residue 0.15%, glaze slurry concentration 345g / 200ml, ring shrinkage 12.1%, melting length 58mm.

Embodiment 2

[0025] As shown in the formula sheet in Table 1, wollastonite is 9.71%, and its glaze mainly contains the following substances by weight: SiO 2 59.66%, Al 2 o 3 8.66%, Fe 2 o 3 0.18%, TiO 2 0.04%, CaO 10.15%, MgO 0.96%, K 2 O 3.18%, Na 2 O 1.37%, ZnO 3.47%, ZrO 2 6.72%, Lg.loss 5.30%, and the remaining 0.31% are impurities.

[0026] The preparation method is as follows: the raw materials are prepared according to the above-mentioned components and parts by weight of each component, according to ball: glaze: water = 1.5:4:3, wet ball milling for 12 hours, the glaze after ball milling requires a particle size of 10 microns and a passing rate of 72.85 %, 325 mesh sieve residue 0.10%, glaze slurry concentration 345g / 200ml, ring shrinkage 12.6%, melting length 70mm.

Embodiment 3

[0028] As shown in the formula sheet in Table 1, wollastonite is 13.68%, and its glaze mainly contains the following substances by weight: SiO 2 60.66%, Al 2 o 3 7.68%, Fe 2 o 3 0.22%, TiO 2 0.05%, CaO 10.85%, MgO 0.97%, K 2 O 3.18%, Na 2 O 1.37%, ZnO 3.47%, ZrO 2 6.66%, Lg.loss 4.61%, and the remaining 0.28% are impurities.

[0029] The preparation method is as follows: the raw materials are prepared according to the above components and parts by weight of each component, according to ball: glaze: water = 1.5:4:3, wet ball milling for 12 hours, the glaze after ball milling requires a particle size of 10 microns, and the pass rate is 70.56 %, 325 mesh sieve residue 0.15%, glaze slurry concentration 345g / 200ml, ring shrinkage 12.8%, melting length 75mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com