Preparation method of electrolyte-resistant-type complex mineral gel

A technology of composite minerals and electrolytes, applied in the direction of silicon compounds, chemical instruments and methods, colloid chemistry, etc., can solve the problems of water separation, easy occurrence of aqueous solution systems, and poor anti-electrolyte performance, so as to achieve improved stability, stable product performance, The effect of preventing collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

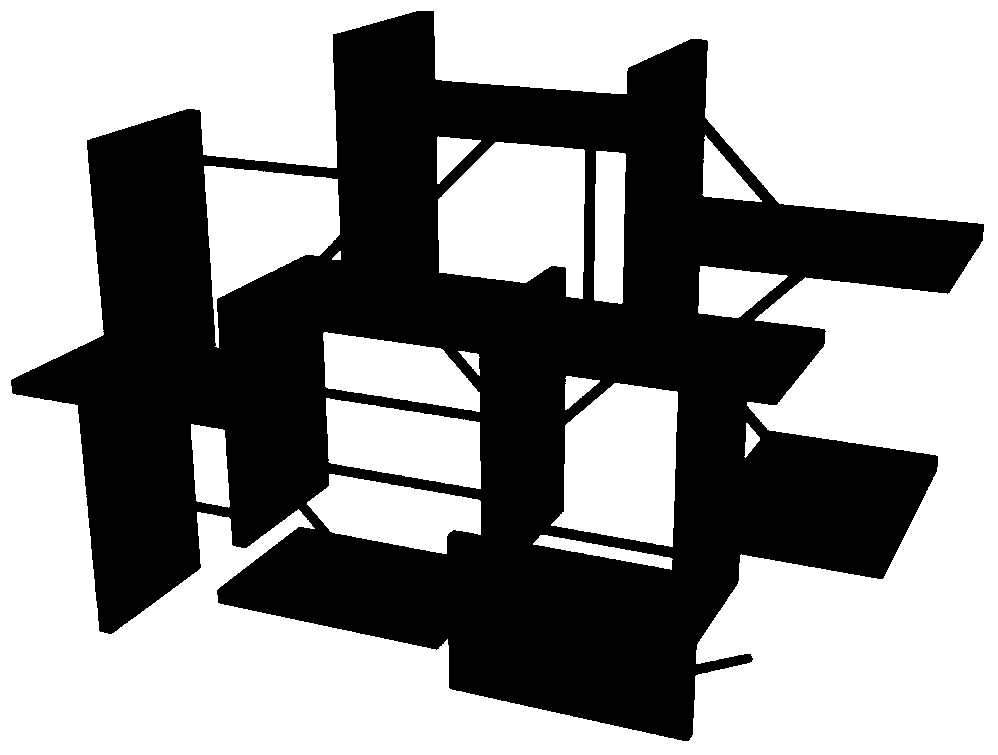

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: A kind of preparation method of anti-electrolyte composite mineral gel

[0045] First prepare the montmorillonite gel slurry, then prepare the modified columnar mineral slurry, and finally compound the prepared montmorillonite gel slurry and the modified columnar mineral slurry; The preparation of glue liquid, the preparation of the second part of the modified columnar mineral slurry and the preparation of the third part of the composite mineral gel;

[0046] The preparation of the first part of montmorillonite gel slurry consists of the following steps:

[0047] In the first step, 200g of raw material bentonite minerals are pulverized to form bentonite mineral powder;

[0048] In the second step, the bentonite mineral powder after pulverization is added into 2000g water to make a slurry, and 0.2g sodium hexametaphosphate and 2g sodium carbonate are added to fully stir, so that the bentonite mineral particles are evenly dispersed in the slurry, wherein, ...

Embodiment 2

[0064] Embodiment 2: A kind of preparation method of anti-electrolyte composite mineral gel

[0065] First prepare the montmorillonite gel slurry, then prepare the modified columnar mineral slurry, and finally compound the prepared montmorillonite gel slurry and the modified columnar mineral slurry; The preparation of glue liquid, the preparation of the second part of the modified columnar mineral slurry and the preparation of the third part of the composite mineral gel;

[0066] The preparation of the first part of montmorillonite gel slurry consists of the following steps:

[0067] In the first step, 200g of raw material bentonite minerals are pulverized to form bentonite mineral powder;

[0068] In the second step, the pulverized bentonite mineral powder is added to 1000g water to make a slurry, and 4g of sodium silicate is added to fully stir, so that the bentonite mineral particles are evenly dispersed in the slurry, wherein the bentonite mineral in the slurry is The we...

Embodiment 3

[0090] Embodiment 3: A kind of preparation method of anti-electrolyte composite mineral gel

[0091] First prepare the montmorillonite gel slurry, then prepare the modified columnar mineral slurry, and finally compound the prepared montmorillonite gel slurry and the modified columnar mineral slurry; The preparation of glue liquid, the preparation of the second part of the modified columnar mineral slurry and the preparation of the third part of the composite mineral gel;

[0092] The preparation of the first part of montmorillonite gel slurry consists of the following steps:

[0093] In the first step, 200g of raw material bentonite minerals are pulverized to form bentonite mineral powder;

[0094] In the second step, the crushed bentonite mineral powder is added to 200g water to make a slurry, and 0.2g sodium pyrophosphate is added to fully stir, so that the bentonite mineral particles are evenly dispersed in the slurry, wherein the bentonite in the slurry is The weight rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com