Sludge powder nano soft soil modifier and preparation method thereof

A modifier and nanotechnology, applied in the field of silt powder nanosoft soil modifier and its preparation, can solve the problems of low tensile strength, slow strength growth, poor toughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

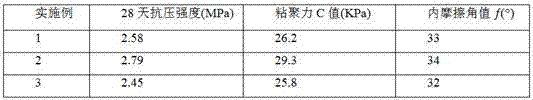

Examples

Embodiment 1

[0023] A silt powder nano-soft soil modifier, made of the following raw materials in parts by weight: 1.8 parts of P.O 42.5R ordinary Portland cement, 2.3 parts of S95 granulated blast furnace slag, 1.8 parts of CL90 quicklime, F.II grade powder 0.6 parts of coal ash, 0.5 parts of nano-scale silica powder, 0.6 parts of composite activator, 0.4 parts of sepiolite fiber, 0.8 part of alkali-resistant glass fiber, 0.8 part of wollastonite fiber, and 1.2 parts of papermaking white mud.

[0024] The composite activator is made by mixing polyacrylic acid, polycarboxylate water reducer, aluminum potassium sulfate, calcium sulfate, sodium sulfate and magnesium sulfate in a weight ratio of 100:15:13:5:4:1.

[0025] The preparation method of the composite activator is as follows: heat polyacrylic acid to 70°C, add polycarboxylate water reducer, stir for 13 minutes, then add aluminum potassium sulfate, calcium sulfate, sodium sulfate and magnesium sulfate, and stir for 5 minutes, That is,...

Embodiment 2

[0030] A silt powder nano-soft soil modifier, made of the following raw materials in parts by weight: 1.9 parts of P.O 42.5R ordinary Portland cement, 2.2 parts of S95 granulated blast furnace slag, 1.9 parts of CL90 quicklime, F.II grade powder 0.5 parts of coal ash, 0.6 parts of nano-scale silica powder, 0.6 parts of composite activator, 0.4 parts of sepiolite fiber, 0.7 part of alkali-resistant glass fiber, 0.9 part of wollastonite fiber, and 1.0 part of papermaking white mud.

[0031] The composite activator is made by mixing polyacrylic acid, polycarboxylate water reducer, aluminum potassium sulfate, calcium sulfate, sodium sulfate and magnesium sulfate in a weight ratio of 100:17:10:6:3:2.

[0032] The preparation method of the composite activator is as follows: heat polyacrylic acid to 72°C, add polycarboxylate water reducer, stir for 11 minutes, then add aluminum potassium sulfate, calcium sulfate, sodium sulfate and magnesium sulfate, and stir for 7 minutes, That is, ...

Embodiment 3

[0037] A silt powder nano-soft soil modifier, made of the following raw materials in parts by weight: 2.0 parts of P.O 42.5R ordinary Portland cement, 2.1 parts of S95 granulated blast furnace slag, 2.0 parts of CL90 quicklime, F.II grade powder 0.5 parts of coal ash, 0.6 parts of nano-scale silica powder, 0.5 parts of composite activator, 0.5 parts of sepiolite fiber, 0.6 part of alkali-resistant glass fiber, 1.0 part of wollastonite fiber, and 0.8 part of papermaking white mud.

[0038] The composite activator is made by mixing polyacrylic acid, polycarboxylate water reducer, aluminum potassium sulfate, calcium sulfate, sodium sulfate and magnesium sulfate in a weight ratio of 100:20:7:7:3:3.

[0039] The preparation method of the composite activator is: heating polyacrylic acid to 75°C, adding polycarboxylate water reducer, stirring for 10 minutes, then adding aluminum potassium sulfate, calcium sulfate, sodium sulfate and magnesium sulfate, and stirring for 10 minutes, Tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com