Intelligent control method and system for polishing equipment

An equipment and rough polishing technology, applied in the field of intelligent control method and system of polishing equipment, can solve problems such as the increase of polishing defect rate, and achieve the effect of improving polishing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

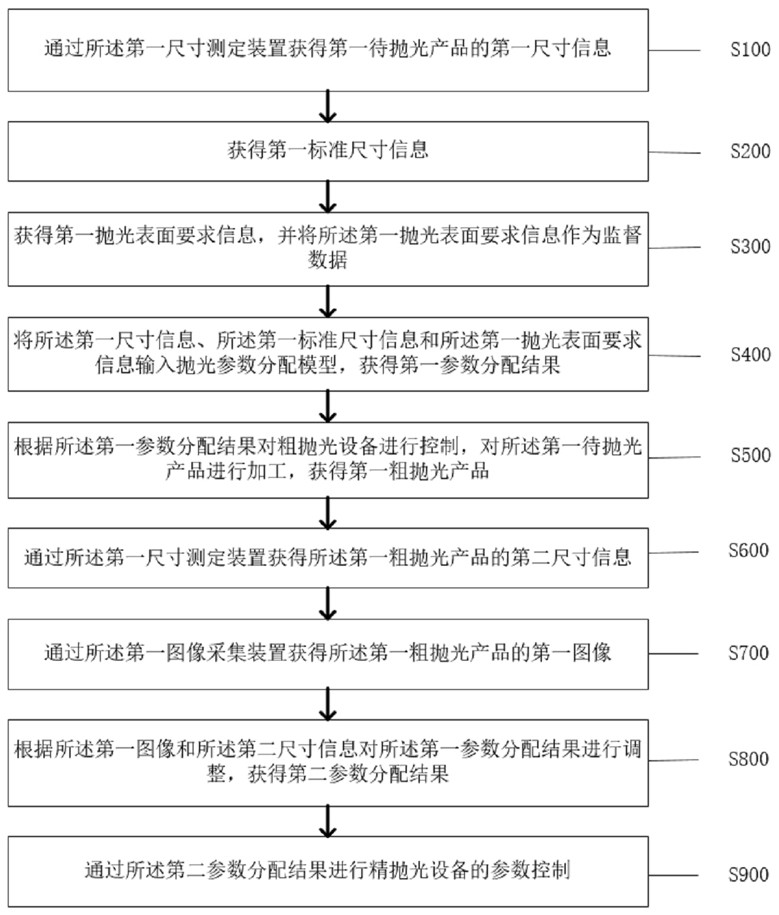

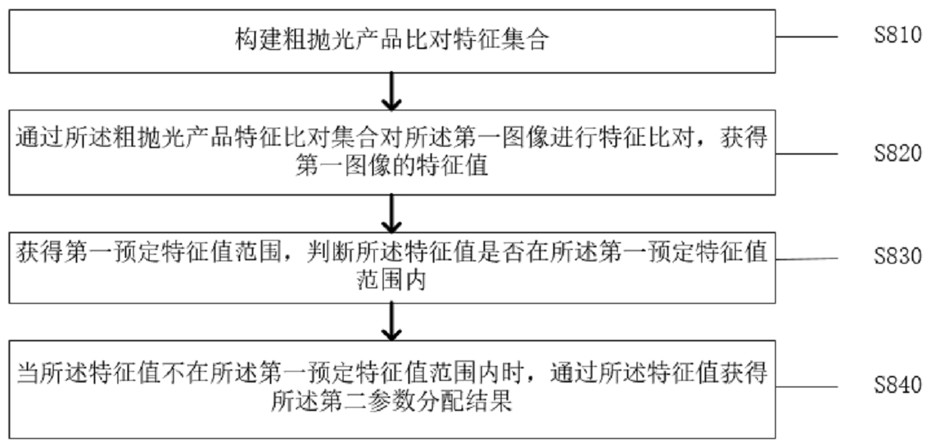

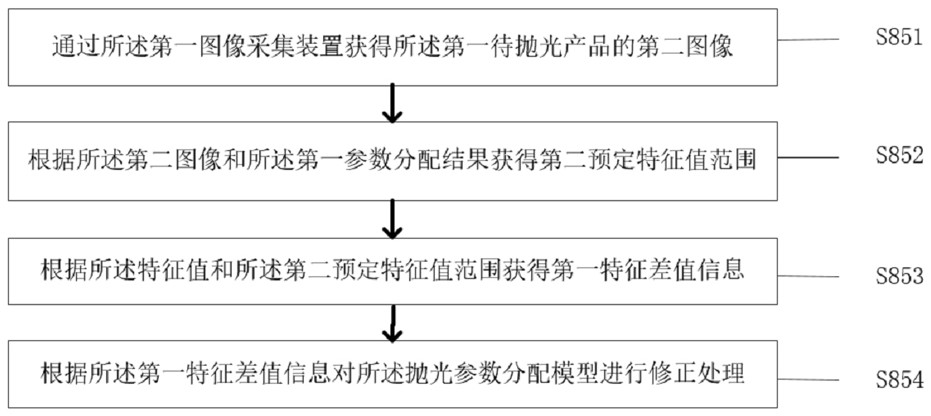

[0030] Such as figure 1 As shown, the embodiment of the present application provides an intelligent control method for polishing equipment, wherein the method is applied to an intelligent parameter control system, and the system is communicatively connected with the first image acquisition device and the first dimension measurement device , the method includes:

[0031] Step S100: Obtain the first size information of the first product to be polished by the first size measuring device;

[0032] Specifically, the intelligent parameter control system is a system for joint intelligent distribution of rough polishing and fine polishing parameters, and the first image acquisition device is a device capable of image acquisition. Generally speaking, the device is an optical An image capture instrument, such as a CCD camera, the first size measuring device is a device capable of size measurement, according to the difficulty of the measured size, accuracy requirements, etc., the first ...

Embodiment 2

[0084] Based on the same inventive concept as the intelligent control method of the polishing equipment in the foregoing embodiments, the present invention also provides an intelligent control system of the polishing equipment, such as Figure 8 As shown, the system includes:

[0085] A first obtaining unit 11, the first obtaining unit 11 is used to obtain the first size information of the first product to be polished through a first size measuring device;

[0086] A second obtaining unit 12, the second obtaining unit 12 is used to obtain the first standard size information;

[0087] A third obtaining unit 13, the third obtaining unit 13 is configured to obtain first polishing surface requirement information, and use the first polishing surface requirement information as supervisory data;

[0088] A fourth obtaining unit 14, the fourth obtaining unit 14 is used to input the first size information, the first standard size information and the first polishing surface requirement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com