On-board fixture for loading and unloading

A technology of jigs and material trucks, which is applied in the field of jigs, and can solve problems such as polysilicon ingot bruises, operator pinch injuries, and reduced production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

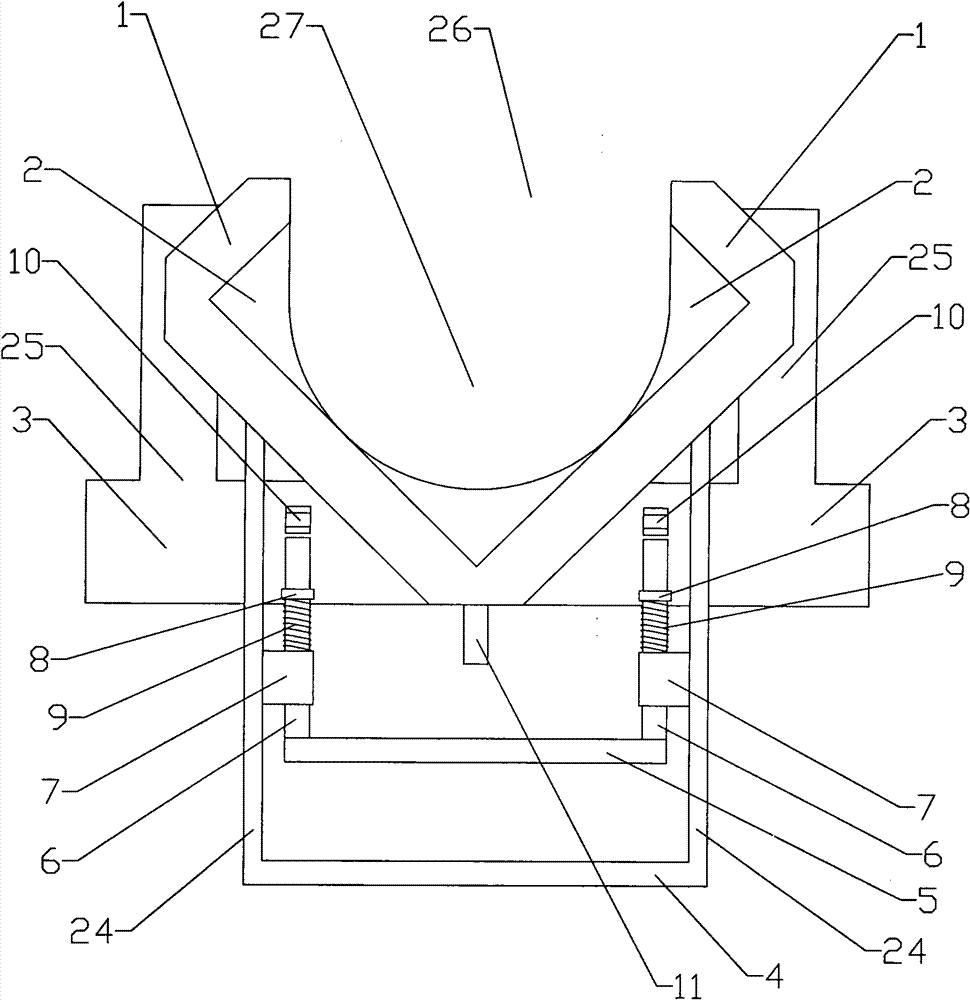

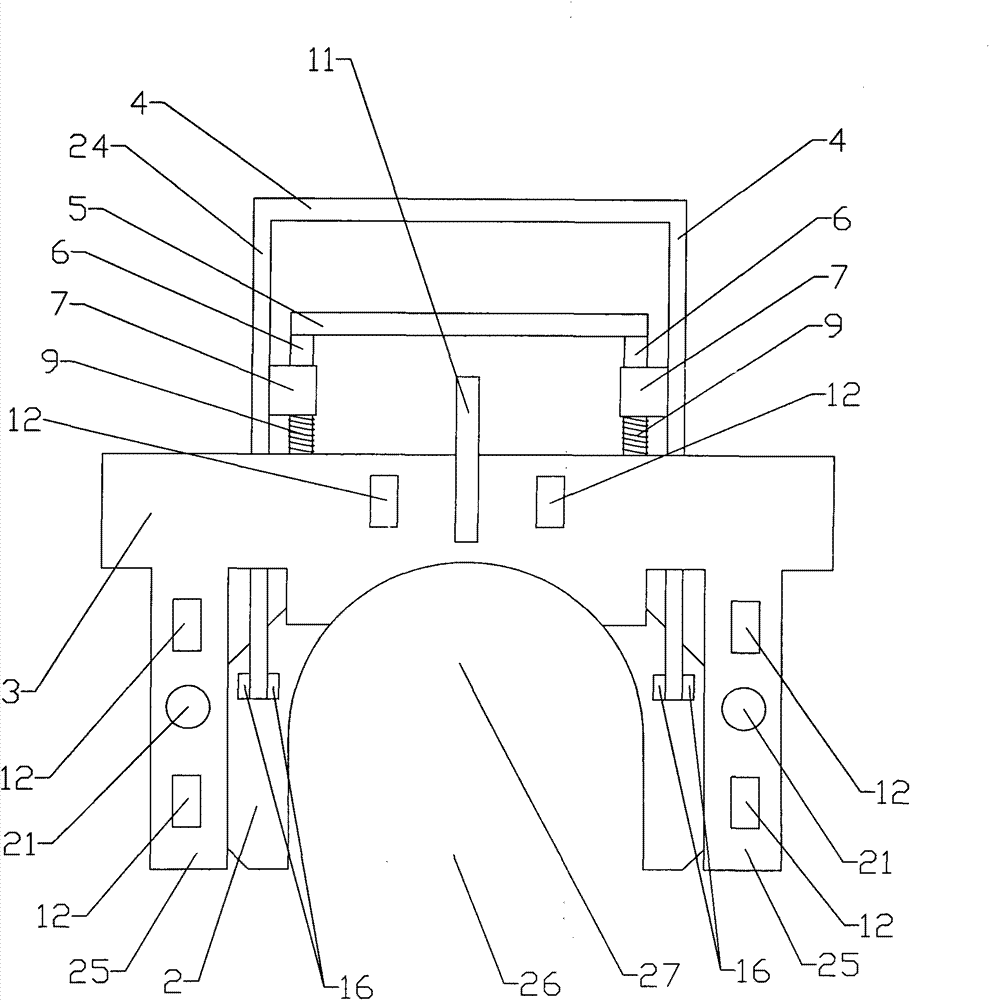

[0028] Examples such as figure 1 and Figure 7 As shown, a vehicle-mounted jig for loading and unloading materials includes a feeding car and a positioning device, and the positioning device is slidably connected to the feeding car.

[0029] like figure 1 and figure 2 As shown, the material cart includes a loading platform 2, and the center of the loading platform 2 is provided with a through hole 27 for accommodating the carrying device of the polishing machine. The loading platform 2 has an opening 26, and the width of the opening 26 is equal to the diameter of the through hole 27. Object stage 2 is provided with positioning frame 1, and positioning frame 1 is a strip-shaped square with three corners, and the sides on both sides of opening 26 are short sides of positioning frame 1, and the other two sides are long sides of positioning frame 1, through holes 27 is tangent to positioning frame 1.

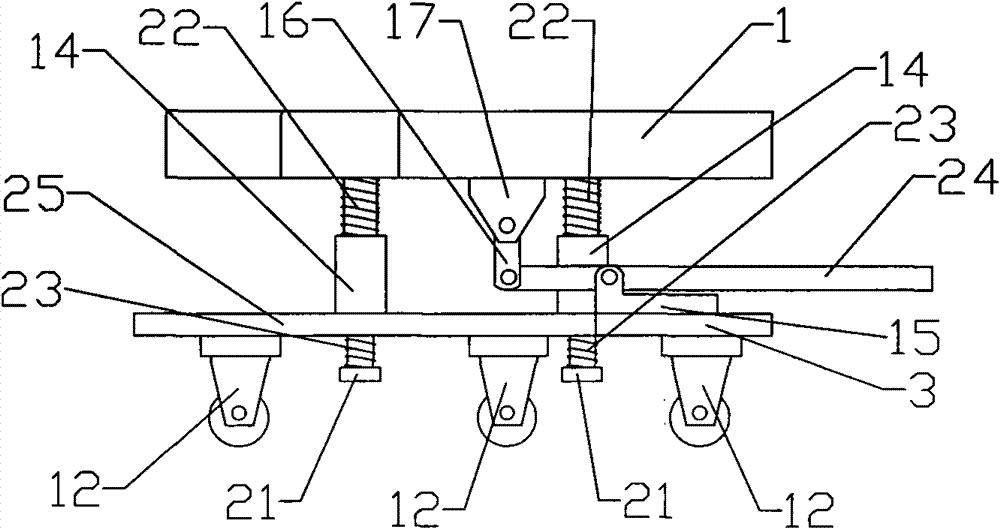

[0030] like image 3 As shown, the bottom of the stage 2 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com