Polishing equipment

A kind of optical equipment and equipment technology, applied in the direction of metal processing equipment, used abrasive processing devices, abrasives, etc., can solve the problems of affecting the glass yield, slow production cycle, and low yield rate of 3D glass, so as to reduce the damage wait time The probability of sweeping the product and the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The light-sweeping device will be further described below in conjunction with the accompanying drawings and specific embodiments.

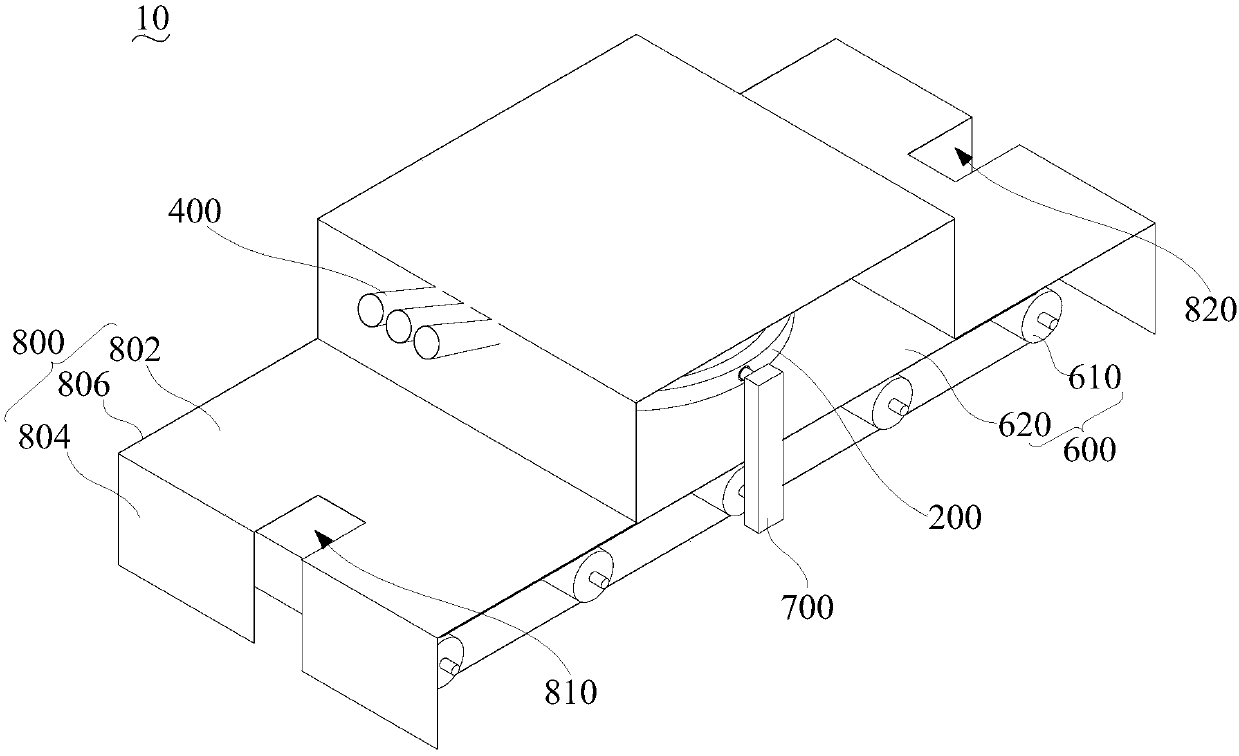

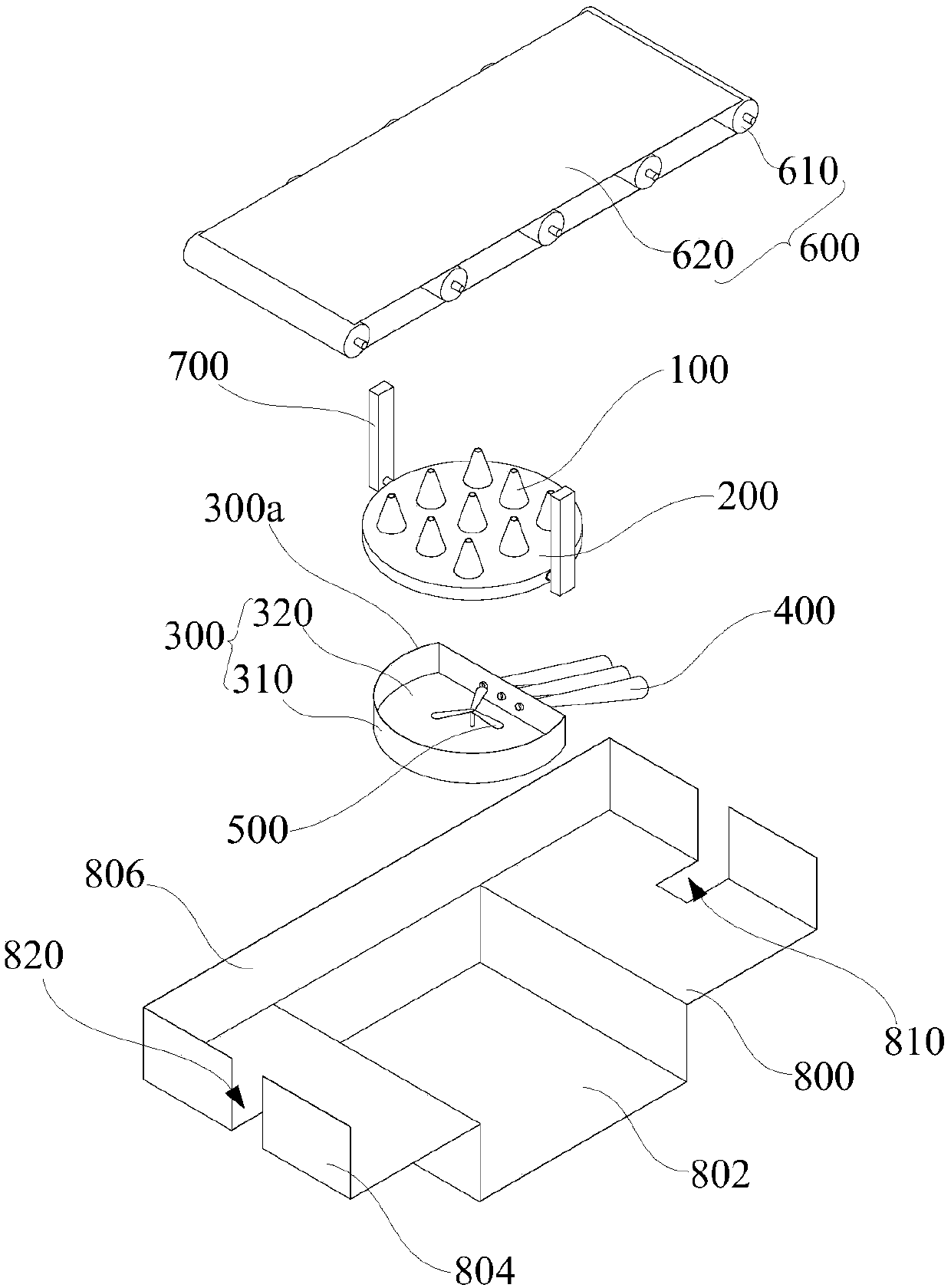

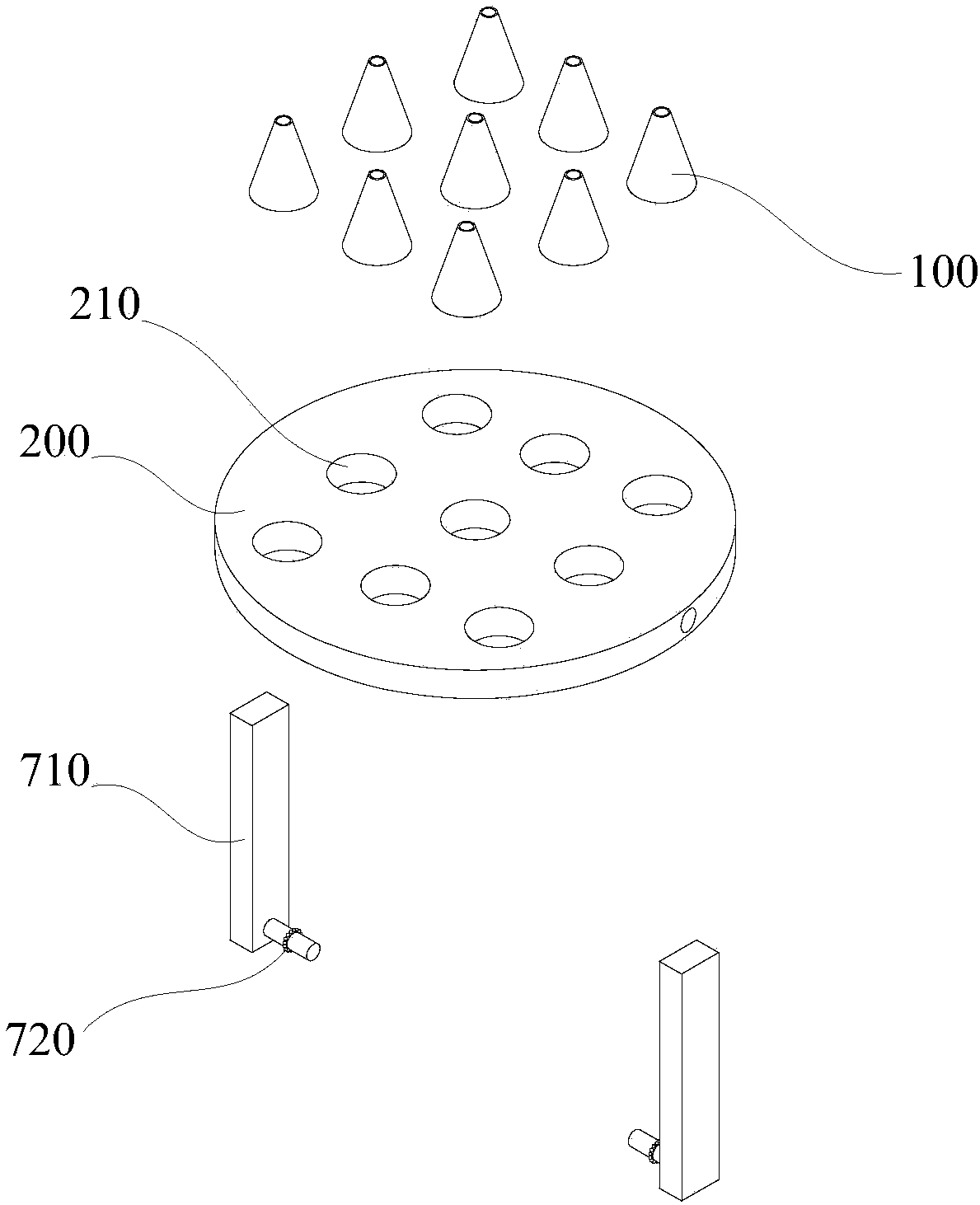

[0023] Such as figure 1 and figure 2 As shown, the sweeping device 10 according to an embodiment of the present invention includes a high-pressure spray gun 100 , a rotating disk 200 , an abrasive shell 300 , a feeding tube 400 , a homogeneous mixer 500 , a carrying assembly 600 , a rotating support frame 700 and a housing 800 .

[0024] The high-pressure spray gun 100 is used to be spaced apart from the product to be cleaned, and the high-pressure spray gun 100 can spray abrasives onto the product to be cleaned to sweep the product to be cleaned, so that the above-mentioned light-sweeping device 10 is non-destructive when cleaning the product. Heavy pressure-non-contact sweeping can effectively reduce the probability of damaging the product to be swept and improve the yield of the product to be swept. Moreover, the high-pressure spray g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com