Maintaining pad having high-precision flatness

A technology for retaining pads and average diameters, applied in electrical components, work carriers, semiconductor/solid-state device manufacturing, etc. Excellent buffer layer, increased strength and abrasion resistance, improved overall compressibility and compression recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Compression recovery of polyurethane foam pads according to the content ratio of methylenediphenyldiisocyanate (MDI) to polyol

[0028] After the molding of the polyurethane foam pad using the resin composition in which the content ratio of MDI to the polyol in the resin composition was increased, the compressibility and the compression recovery thereof were respectively measured.

[0029] The results are shown in Table 1. As the content of MDI relative to polyol increases, the compressibility decreases significantly but the compression recovery increases.

[0030] Table 1:

[0031] MDI / Polyol(%)

Embodiment 2

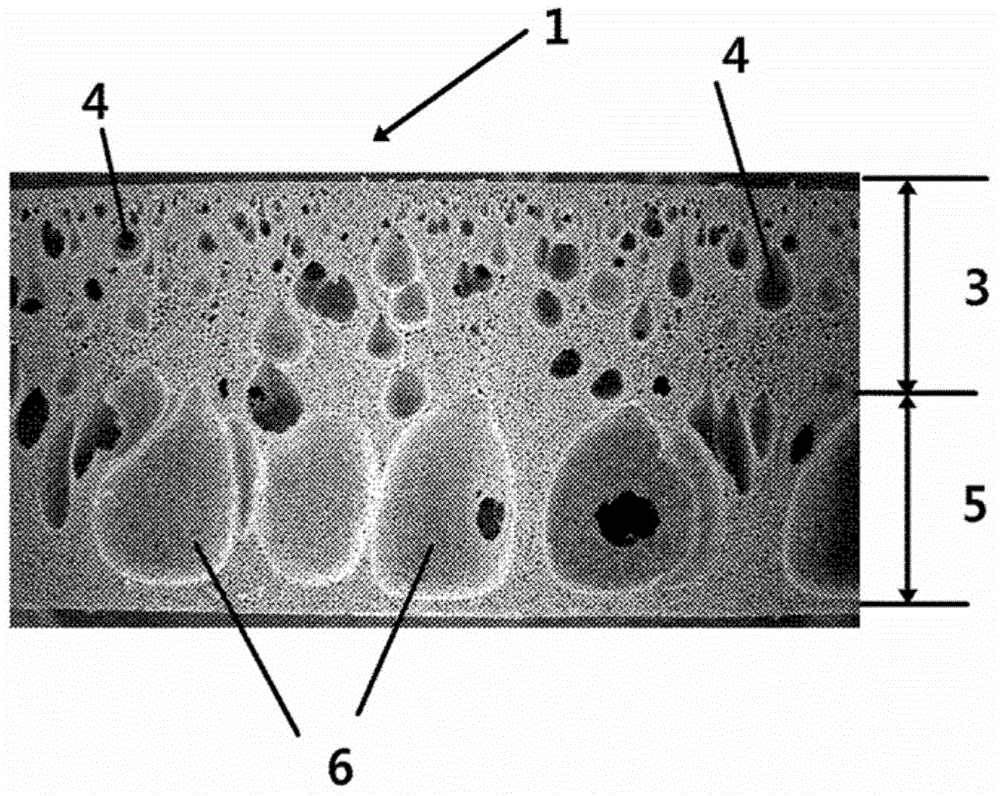

[0033] The surface solidification speed of the resin is increased and the urethane foam pad 1 is molded using a resin polymerized by a prepolymer method that increases the content of hard segments of the polymerized resin. As a result, minute foams are formed within 50% of the entire thickness of the urethane foam pad 1, and giant foams are formed in a region of 60 to 90% of the entire thickness ( figure 1 ).

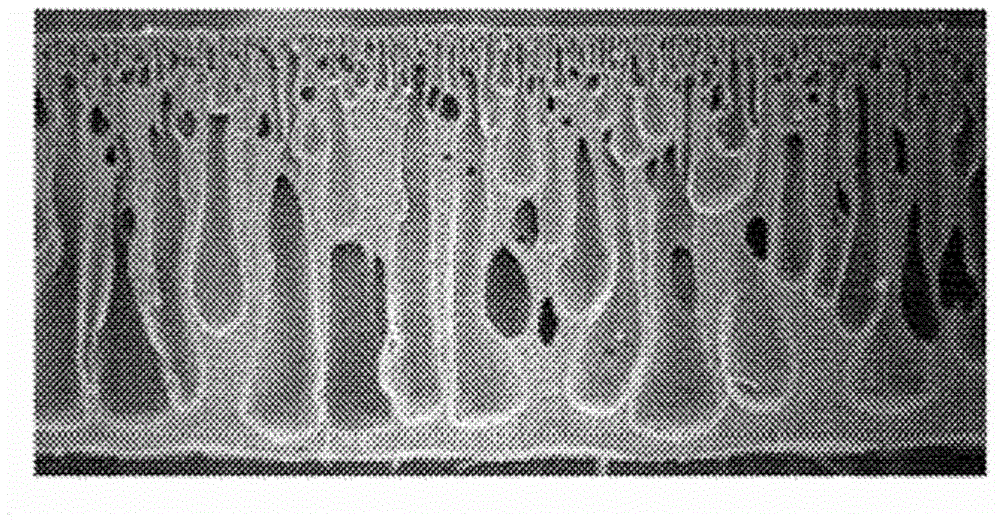

[0034] In contrast, polyurethane foam mats molded using a resin polymerized by a one-step foaming method showed such figure 2 Foam shape and arrangement shown.

Embodiment 3

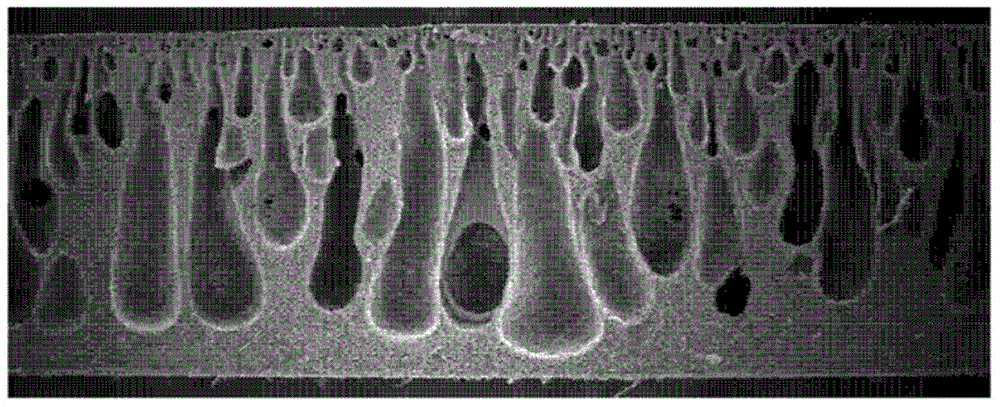

[0036] In the case of adding water within 2% to the resin composition, it was shown as image 3 porosity shown. In contrast, the second comparative example using a general hydrophilic surfactant showed such Figure 4 The foam shape shown.

[0037] Explanation of symbols

[0038] 1: Holding pad

[0039] 3: Upper supporting layer

[0040] 4: micro foam

[0041] 5: Lower buffer layer

[0042] 6: huge foam

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com