Industrial robot demonstration device based on six freedom degree

A technology of industrial robots and demonstration devices, applied in the direction of instruments, chemical instruments and methods, cleaning methods using gas flow, etc., can solve the problems of high maintenance costs, high product prices, expensive diamonds, etc., and achieve the effect of optimizing the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

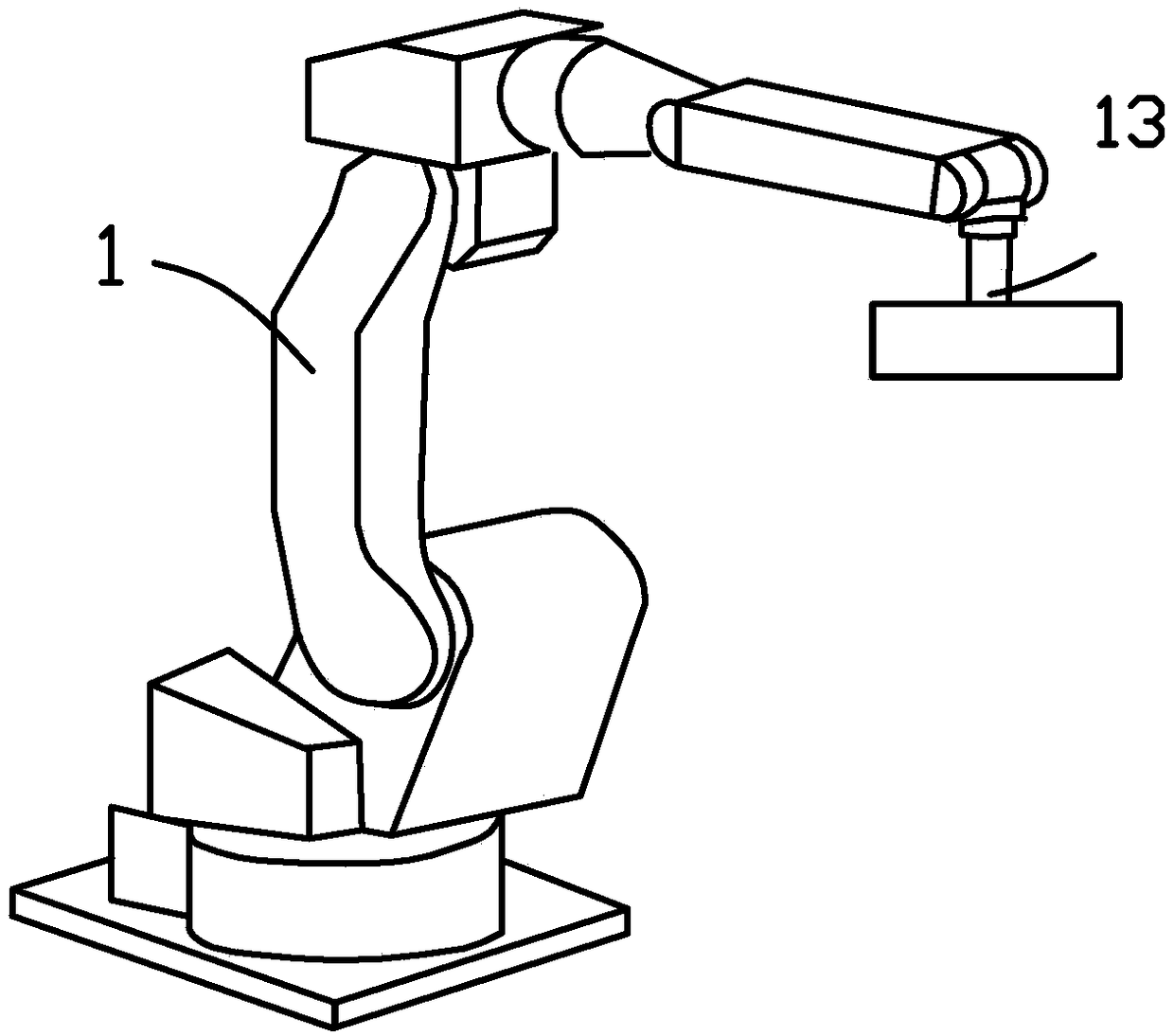

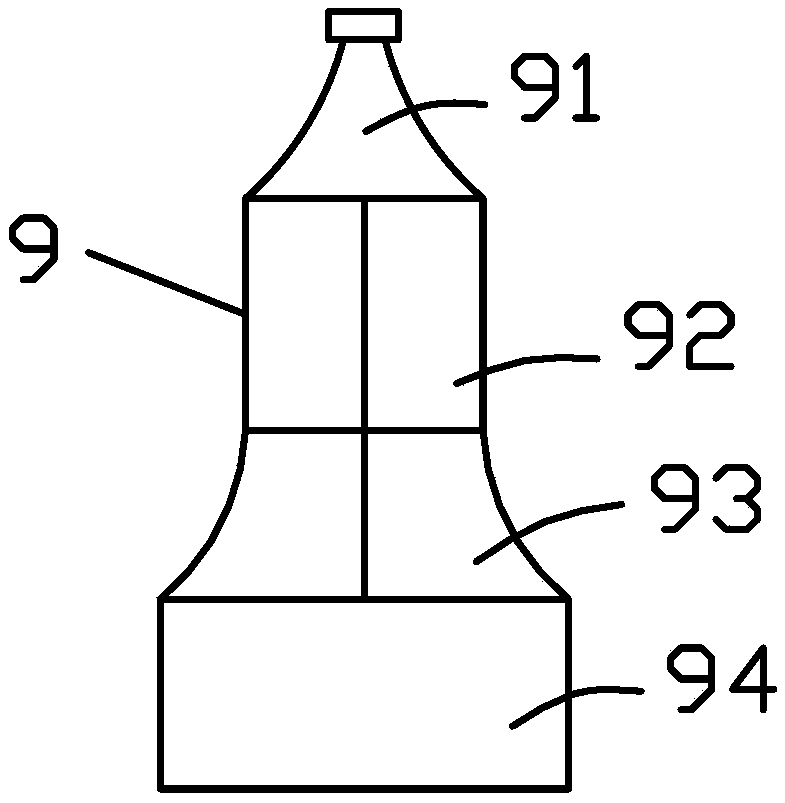

[0025] Such as figure 1 Shown is a working arm 11 with a preset working program, which is a six-degree-of-freedom industrial robot in the prior art; the movement of the working arm 11 can be controlled by the manipulator, and the working arm 11 can also move according to the set action. The fixture 13 includes a fixture 13 body and a pneumatic claw, and the fixture 13 body is correspondingly fixed on the clamping end of the working arm. The bottle mouth portion 91, a rectangular portion 92, and a column corresponding to the workpiece electronic model 9 are respectively provided on the fixture 13 body. Part 93 and the clamping port of the clamping part, and the pneumatic claws are in one-to-one correspondence with the clamping port.

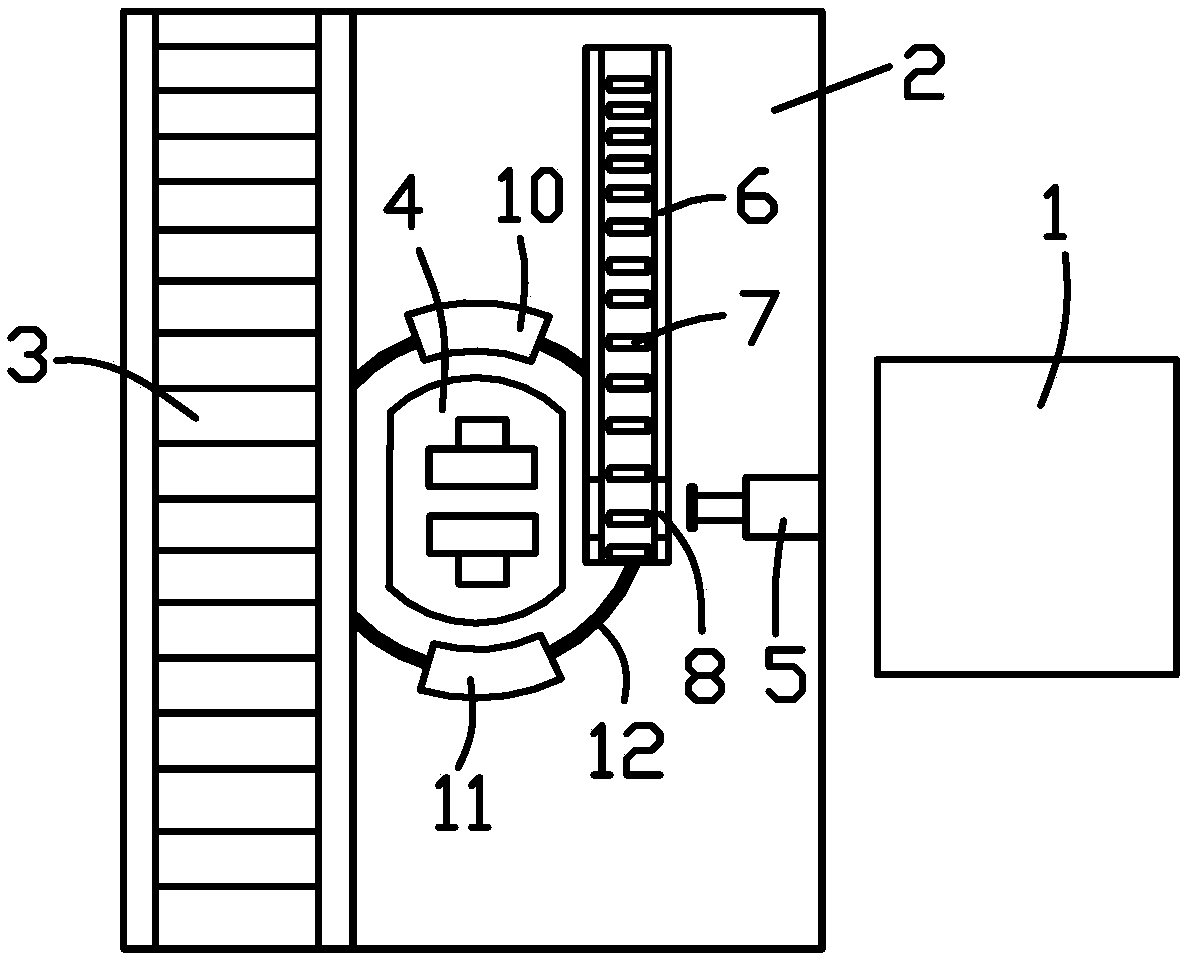

[0026] Such as figure 2 As shown, the pushing device includes a base 2, a conveyor belt 3, a clamping seat 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com