Double-station polishing machine for ceramic wire guide and polishing method of double-station polishing machine

A wire guide and dual-station technology, which is applied in the field of ceramic parts processing, can solve problems such as inability to continuously and efficiently complete, and achieve the effects of achieving continuity, improving polishing efficiency, and avoiding handling operations and switching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

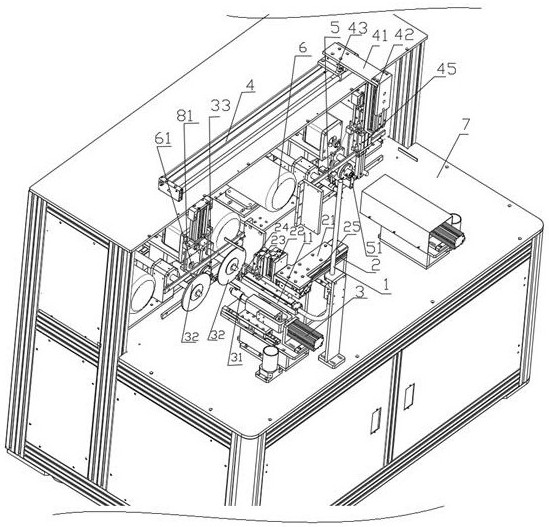

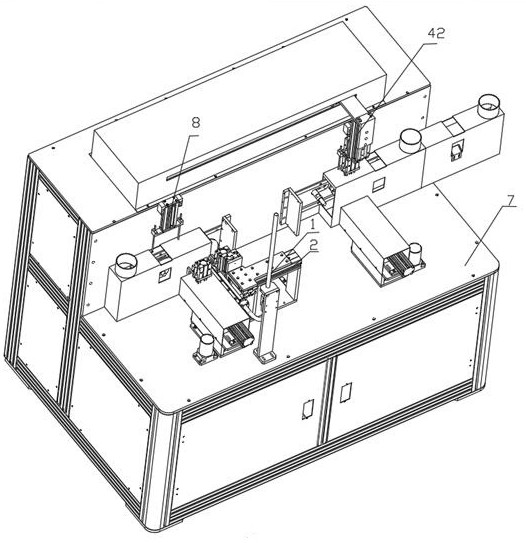

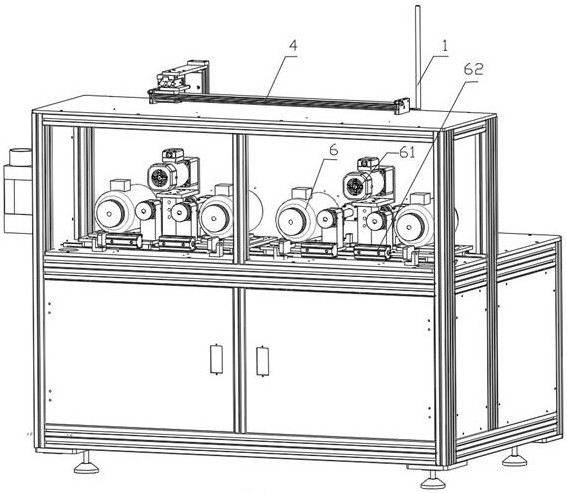

[0025] The invention discloses a double-station polishing machine for a ceramic wire guide, which combines Figure 1-Figure 3 As shown, it includes a feeding mechanism arranged on the operating table 7 and a polishing assembly arranged on one side of the feeding mechanism. The polishing assembly includes a polishing mechanism and a feeding mechanism arranged on the opposite side of the polishing mechanism. The polishing assembly includes a first polishing assembly and a second polishing assembly arranged on one side of the first polishing assembly, a material transfer mechanism is arranged between the two polishing assemblies, and the product to be polished is fed by the feeding mechanism, and the ejector The mechanism supports the product for the first polishing, and the product after the first polishing is moved to the second polishing component by the material transfer mechanism to complete the second polishing. A feeding mechanism for feeding polishing abrasives is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com