Process method for producing glass bodies of glasses

A process method and mirror body technology, applied in the field of technology, can solve problems such as low production efficiency and complicated processing technology, and achieve the effect of improving eyesight and protecting eyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A process for producing a spectacle body, characterized in that the process for producing a spectacle body comprises:

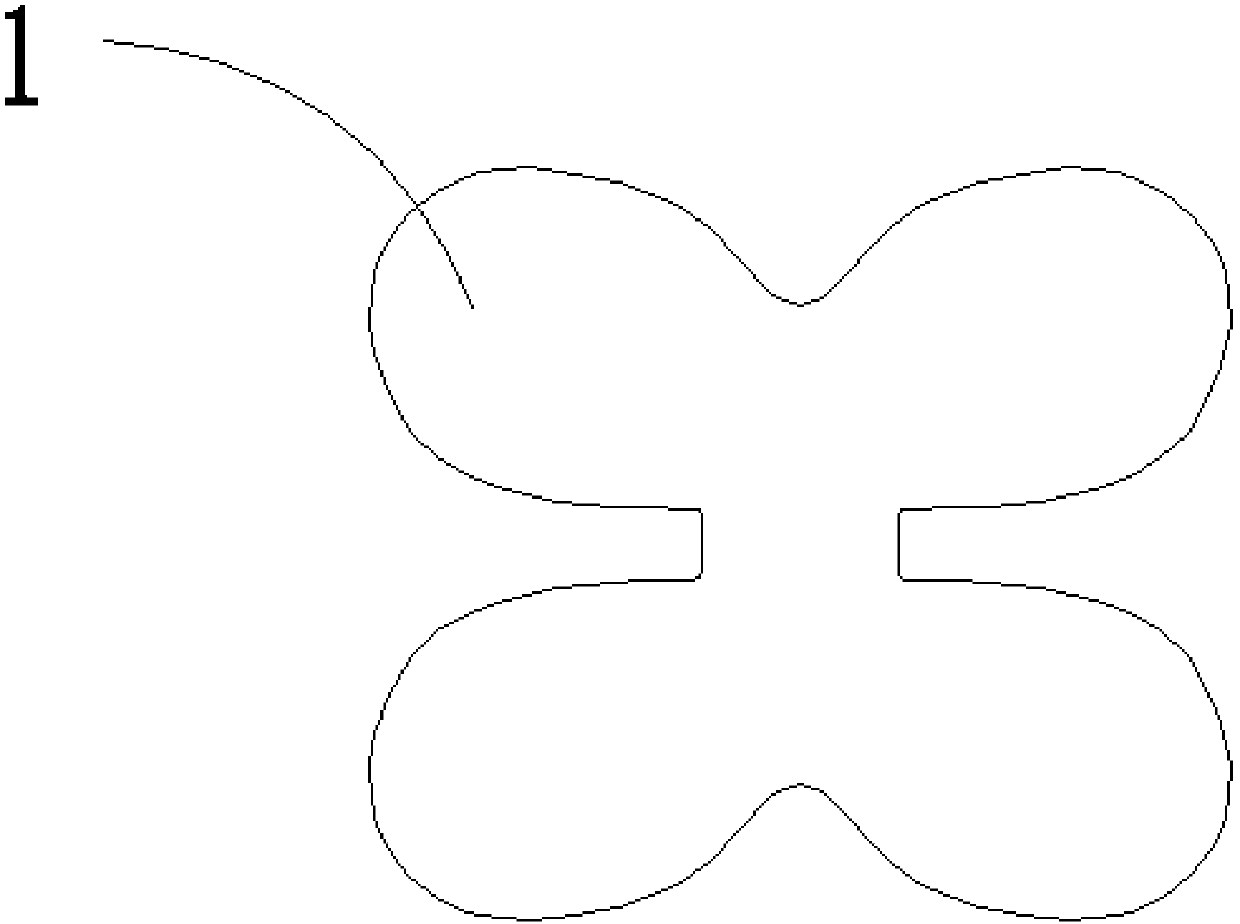

[0043] Processing the material into the embryo material 1 of two glasses bodies;

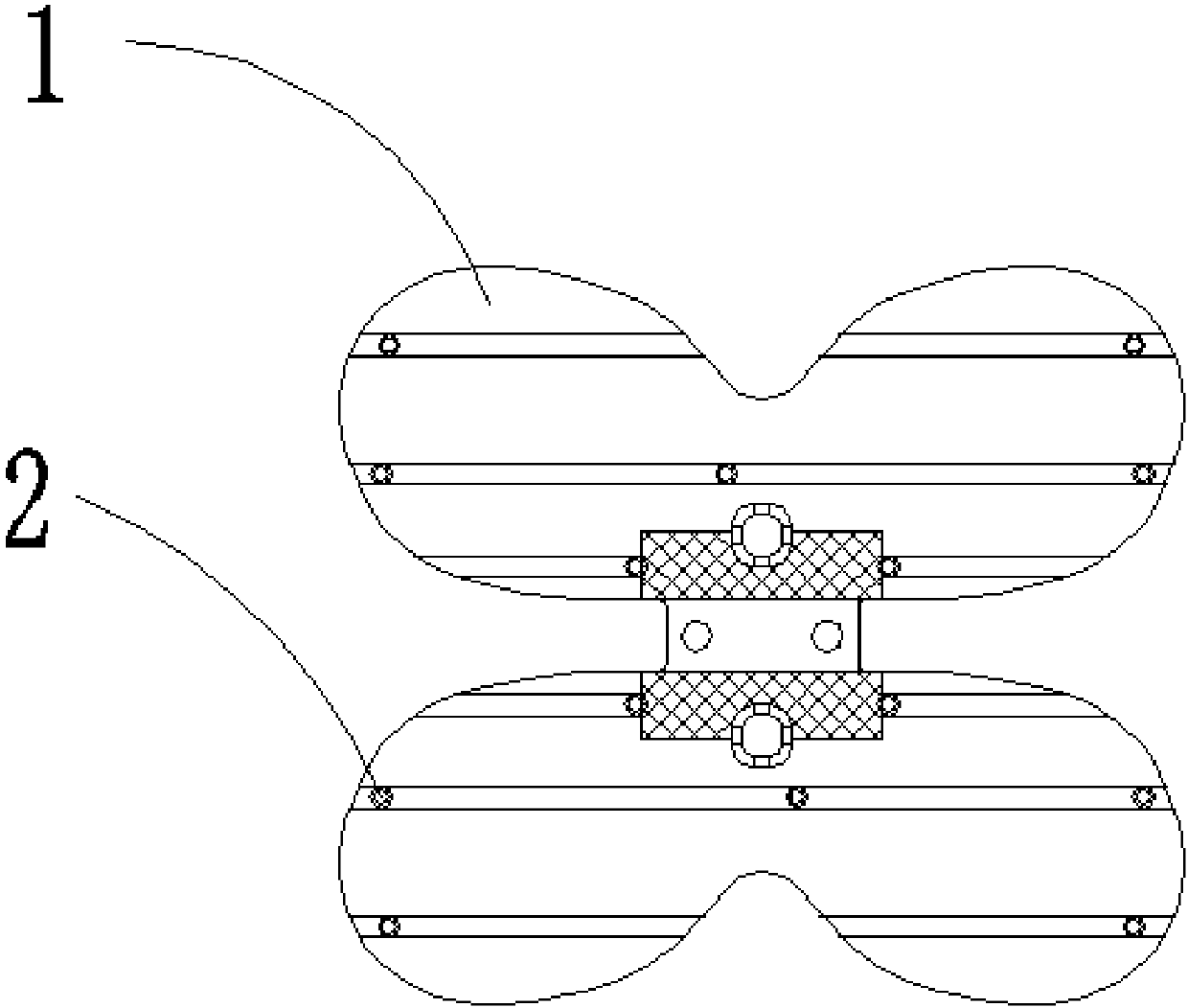

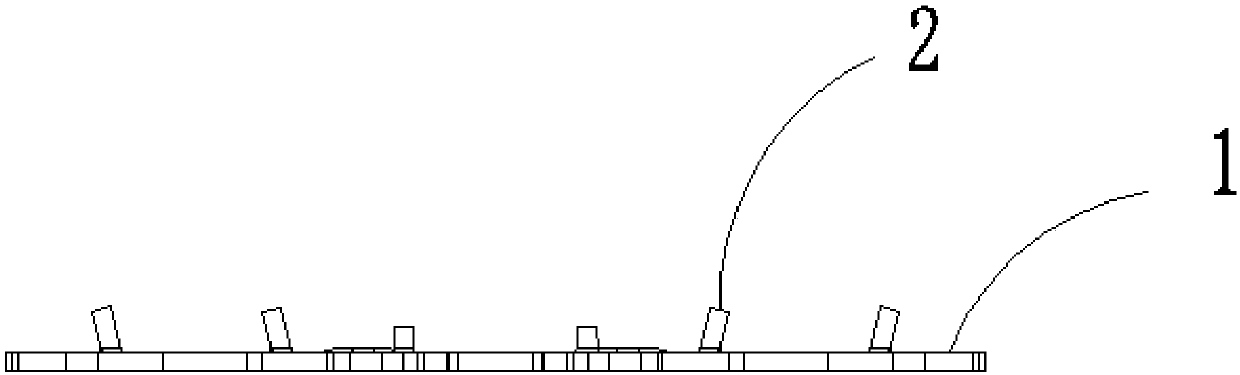

[0044] Carry out CNC processing on the embryo material 1 to form several feet 2;

[0045] Bend the feet 2 on the blank 1 to match the work station;

[0046] Cut off the two spectacle mirror bodies, soak them in oil, and carry out the first forging and pressing, forging and pressing the spectacle mirror bodies into a shape that matches the mold, rough flash and cleaning;

[0047] Continue to soak in oil for the second forging and cleaning;

[0048] Continue to soak in oil for the third forging, fine flashing and cleaning;

[0049] Continue to soak in oil and carry out the fourth forging;

[0050] Polishing, oiling and shaping of products;

[0051] Put it into the aging furnace to harden the product.

[0052] Preferably, the feet 2 are bent at 30 degrees.

[0053] P...

Embodiment 2

[0058] A process for producing a spectacle body, characterized in that the process for producing a spectacle body comprises:

[0059] Processing the material into the embryo material 1 of two glasses bodies;

[0060] Carry out CNC processing on the embryo material 1 to form several feet 2;

[0061] Bend the feet 2 on the blank 1 to match the work station;

[0062] Cut off the two spectacle mirror bodies, soak them in oil, and carry out the first forging and pressing, forging and pressing the spectacle mirror bodies into a shape that matches the mold, rough flash and cleaning;

[0063] Continue to soak in oil for the second forging and cleaning;

[0064] Continue to soak in oil for the third forging, fine flashing and cleaning;

[0065] Continue to soak in oil and carry out the fourth forging;

[0066] Polishing, oiling and shaping of products;

[0067] Put it into the aging furnace to harden the product.

[0068] Preferably, the feet 2 are bent at 30 degrees.

[0069] P...

Embodiment 3

[0074] A process for producing a spectacle body, characterized in that the process for producing a spectacle body comprises:

[0075] Processing the material into the embryo material 1 of two spectacle bodies;

[0076] Carry out CNC processing on the embryo material 1 to form a number of legs 2;

[0077] Bend the foot 2 on the blank 1 to match the work station;

[0078] Cut off the two spectacle mirror bodies, soak them in oil, and carry out the first forging and pressing, forging and pressing the spectacle mirror bodies into a shape that matches the mold, rough burrs and cleaning;

[0079] Continue to soak in oil for the second forging and cleaning;

[0080]Continue to soak in oil for the third forging, fine flashing and cleaning;

[0081] Continue to soak in oil and carry out the fourth forging;

[0082] Polishing, oiling and shaping of products;

[0083] Put it into the aging furnace to harden the product.

[0084] Preferably, the feet 2 are bent at 30 degrees.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com