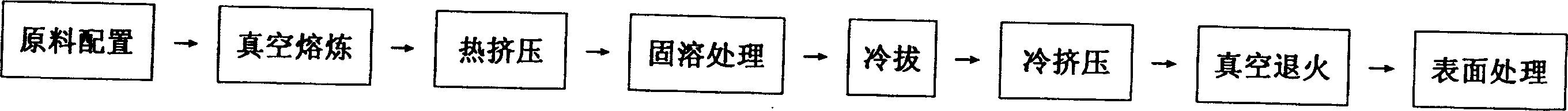

Manufacturing method of electrode cap used for welding automobile coated steel plate

A manufacturing method and electrode cap technology, which is applied to electrode accessories, electrode features, welding equipment, etc., can solve the problems of high processing cost, low efficiency, and the inability of the electrode cap to adapt to the welding of automotive coated steel plates, etc., so as to avoid the tendency of alloying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

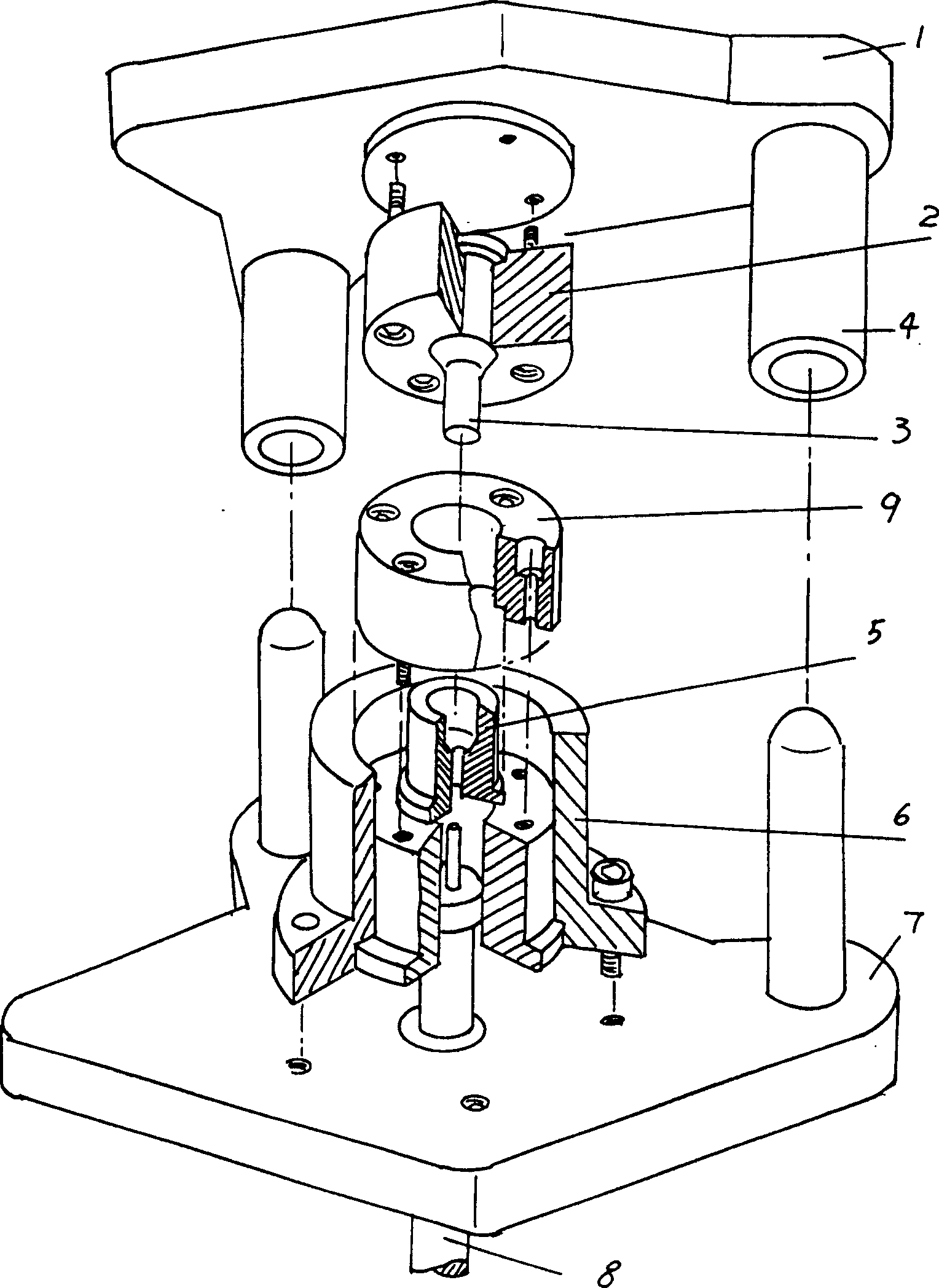

Examples

Embodiment 1

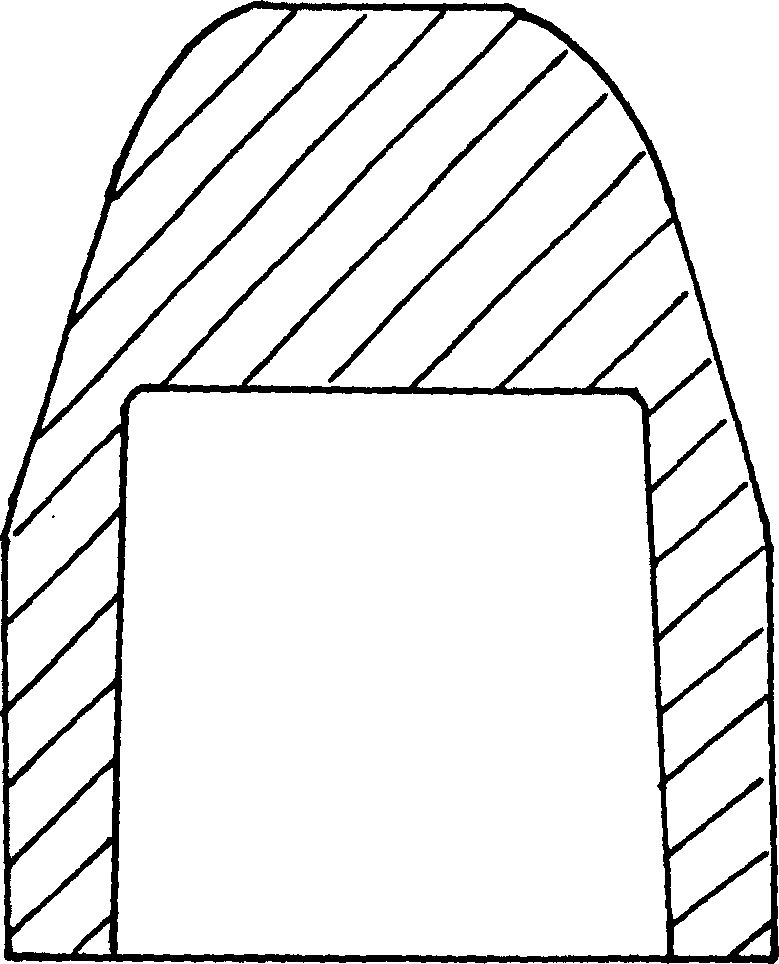

[0028] Take the production of a spherical electrode cap with a specification of Φ16mm×23mm as an example.

[0029] (1) Accurately weigh 99.2% of the standard cathode copper that meets the requirements of the national standard GB467-1997, and 0.6 chromium powder that meets the requirements of the national standard GB2211-87 produced and sold by Jinzhou Jia Alloy Factory with a purity of 99.5% through a 40-mesh sieve. % and zirconium sponge 0.15% produced and sold by Jinzhou Ferroalloy Factory with a purity of more than 98% through a 40-mesh sieve and meeting the requirements of the YB69-65 metallurgical standard, and the brand name MG23A produced by China Jiangsu Suzhou Tianyi Metal Material Co., Ltd. Magnesium 0.05%;

[0030] (2) Fully mix the above-mentioned raw materials, put them into a vacuum furnace for melting, take them out of the furnace when the furnace temperature reaches 1250° C., pour them into a circular mold, and demould after cooling to obtain an ingot billet; ...

Embodiment 2

[0038] Take the production of a spherical electrode cap with a specification of Φ16mm×20mm as an example (replace the corresponding punch 3 and die 5).

[0039] (1) Accurately weigh 99.3% of high-purity cathode copper that meets the requirements of the national standard GBB467-1997, and 0.5% chromium powder that meets the requirements of the national standard GB2211-87 produced and sold by Jinzhou Ferroalloy Factory with a purity of more than 99.5% through a 40-mesh sieve. % and zirconium sponge 0.12% produced and sold by Jinzhou Jia Alloy Factory with a purity of more than 98% through a 40-mesh sieve and meeting the requirements of the YB69-65 metallurgical standard, and the brand produced by China Jiangsu Suzhou Tianyi Metal Material Co., Ltd. is Magnesium 0.08% of MG23A;

[0040] (2) Mix the above-mentioned raw materials thoroughly, put them into a vacuum furnace for melting, take them out of the furnace when the furnace temperature reaches 1290°C, pour them into a circular c...

Embodiment 3

[0048] Take the manufacture of a spherical electrode cap with a specification of Φ13mm×20mm as an example (replace the punch 3 and the die 5 with corresponding specifications).

[0049] (1) Accurately weigh 99.4% of the standard cathode copper that meets the requirements of the national standard GB467-1997, and 0.4% of chromium powder that meets the requirements of the national standard GB2211-87 produced and sold by Jinzhou Ferroalloy Factory with a purity of more than 99.5% through a 40-mesh sieve And zirconium sponge 0.1% produced and sold by Jinzhou Ferroalloy Factory with a purity of more than 98% through a 40-mesh sieve and meeting the requirements of the YB69-65 metallurgical standard, and MG23A produced by China Jiangsu Suzhou Tianyi Metal Material Co., Ltd. Magnesium 0.1%;

[0050] (2) The above-mentioned raw materials are fully mixed, put into a vacuum furnace for smelting, and when the furnace temperature reaches 1210° C., they are taken out of the furnace, poured i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com