Sandblasted sheet metal box cavity edge grinding robot arm

A mechanical arm and sandblasting technology, which is applied in the direction of abrasive jetting machine tools, spray guns, abrasives, etc., can solve the problems of poor grinding effect, excessive grinding of facades, and narrow space, so as to increase the range of grinding area, improve the grinding effect, and avoid The effect of excessive sanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments, but the scope of implementation of the present invention is not limited thereto.

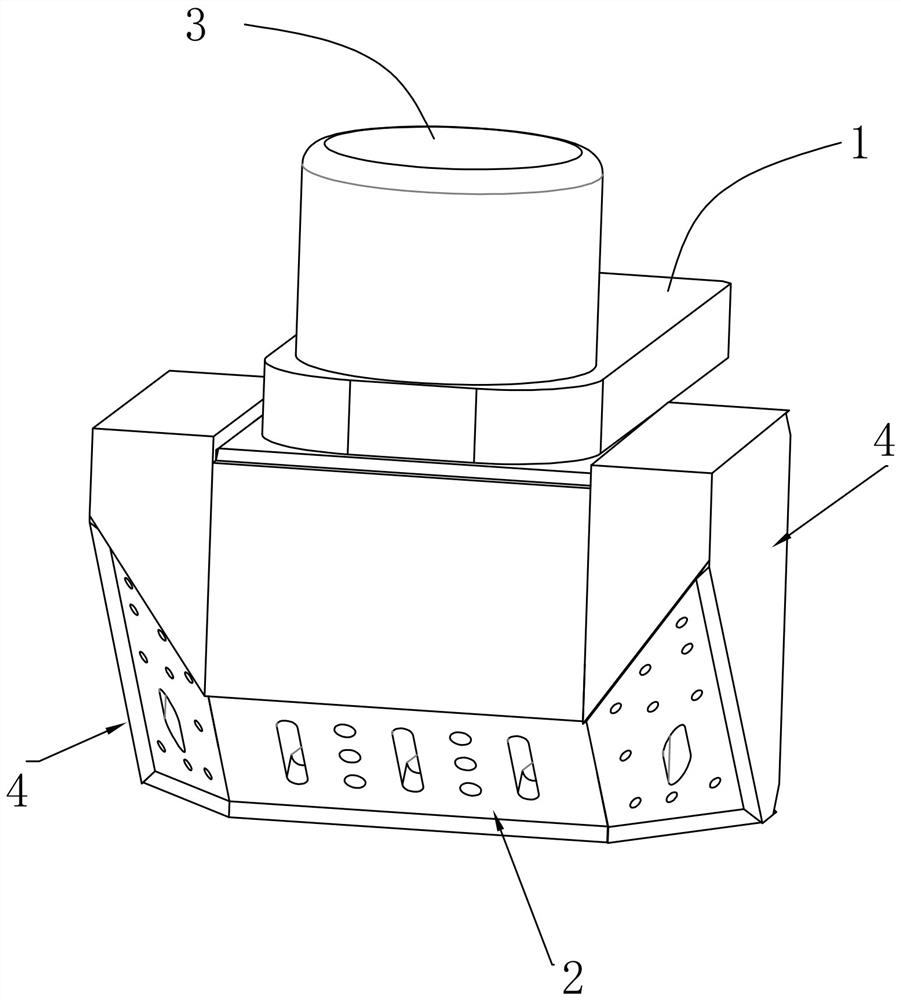

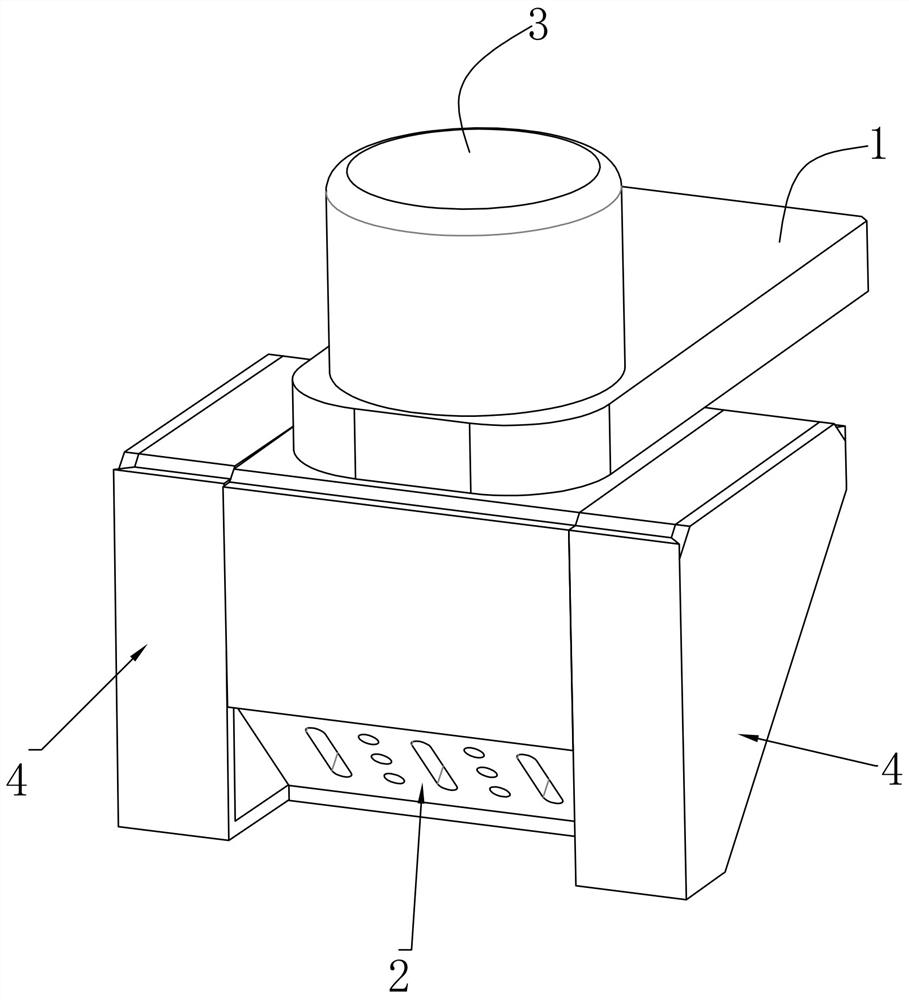

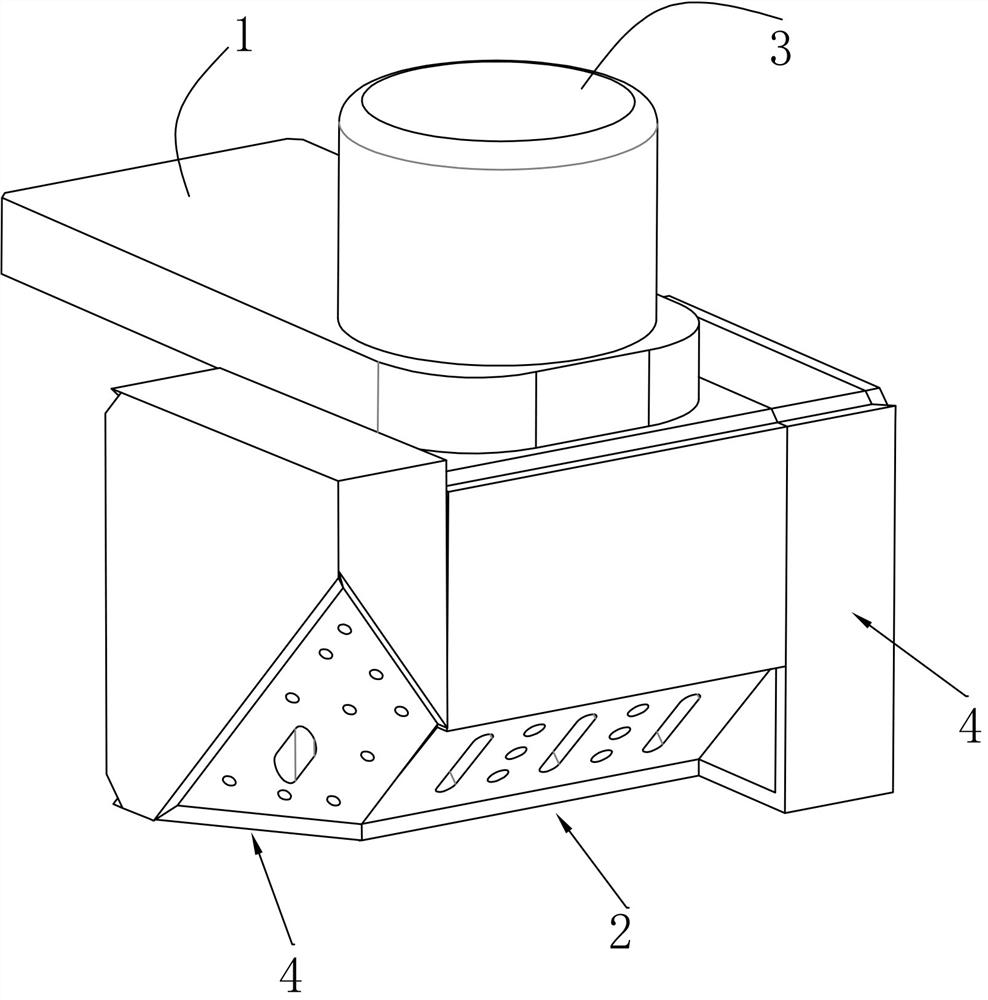

[0025] like Figure 1 to Figure 7 As shown in the figure, a sandblasting type sheet metal box inner cavity edge grinding robot arm described in this embodiment includes a connecting plate 1, a forward sandblasting body 2, a rotary drive mechanism 3 and two lateral sandblasting bodies 4 ;

[0026] The forward sandblasting body 2 is rotatably connected to the connecting plate 1 , and the forward sandblasting body 2 is provided with a first chamfering portion 21 at the junction of the front surface and the bottom surface thereof. The first chamfering portion 21 A plurality of first sand blasting through holes 22 and a plurality of first chip evacuation through holes 23 are provided, and the first sand blasting through holes 22 and the first chip evacuation th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com