Welding joint polishing machine for repair of composite boards

A technology for grinding cars and composite plates, applied in grinding machines, belt grinders, grinding/polishing equipment, etc. It can solve the problems of high labor intensity, low production efficiency, affecting product quality, etc., to ensure consistency and prevent excessive grinding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

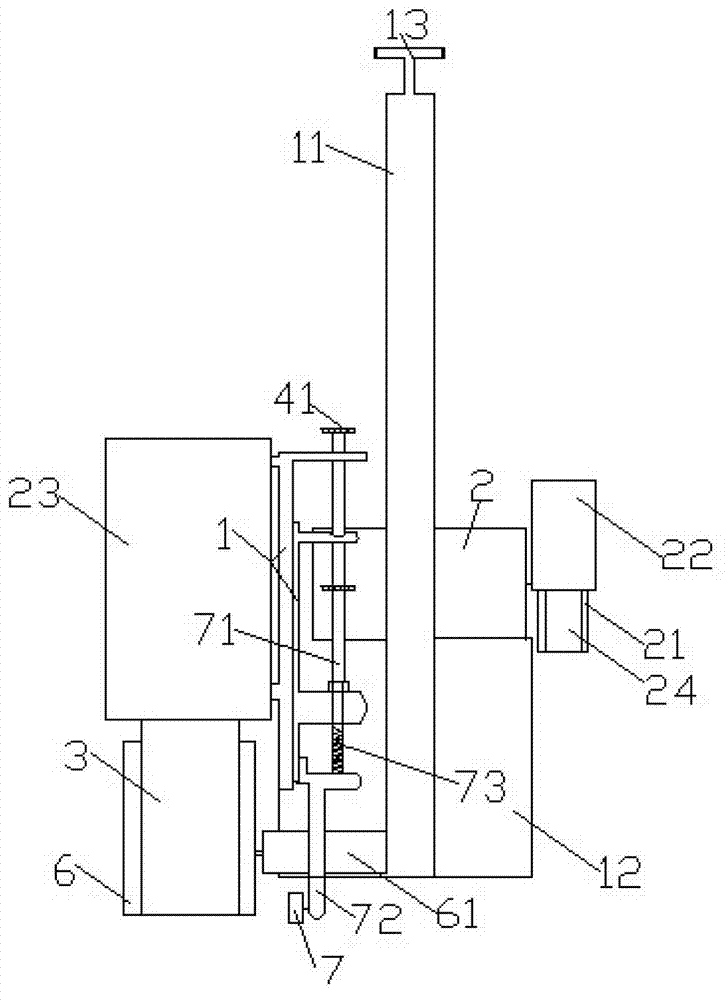

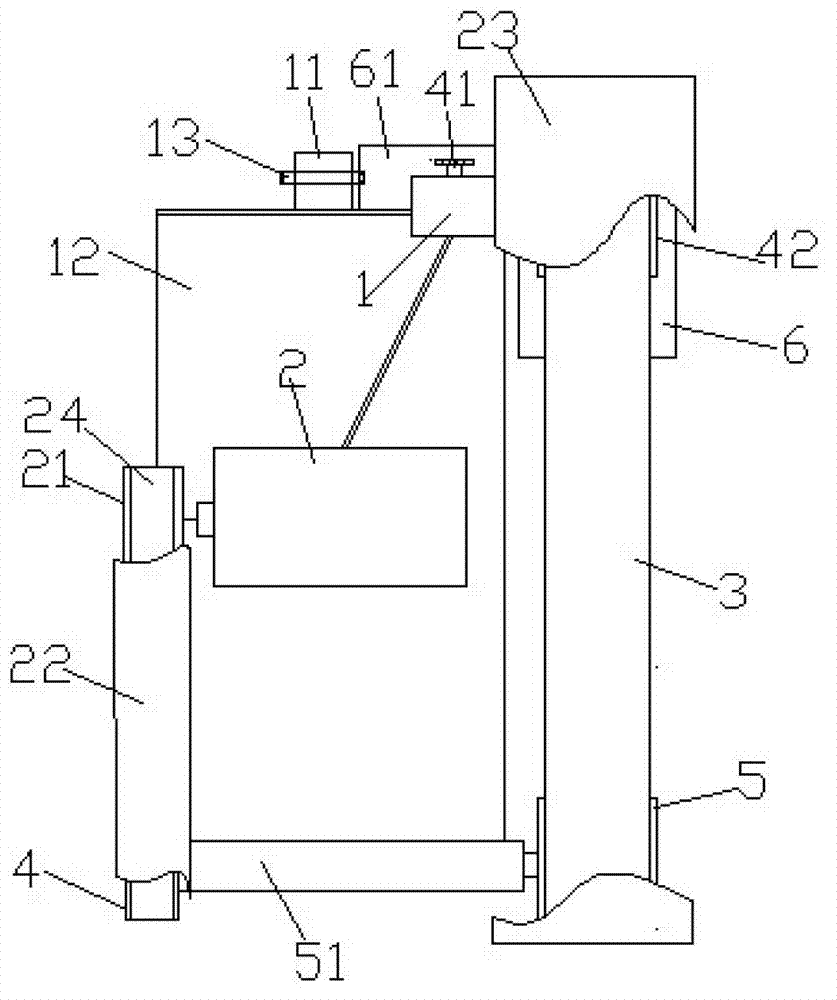

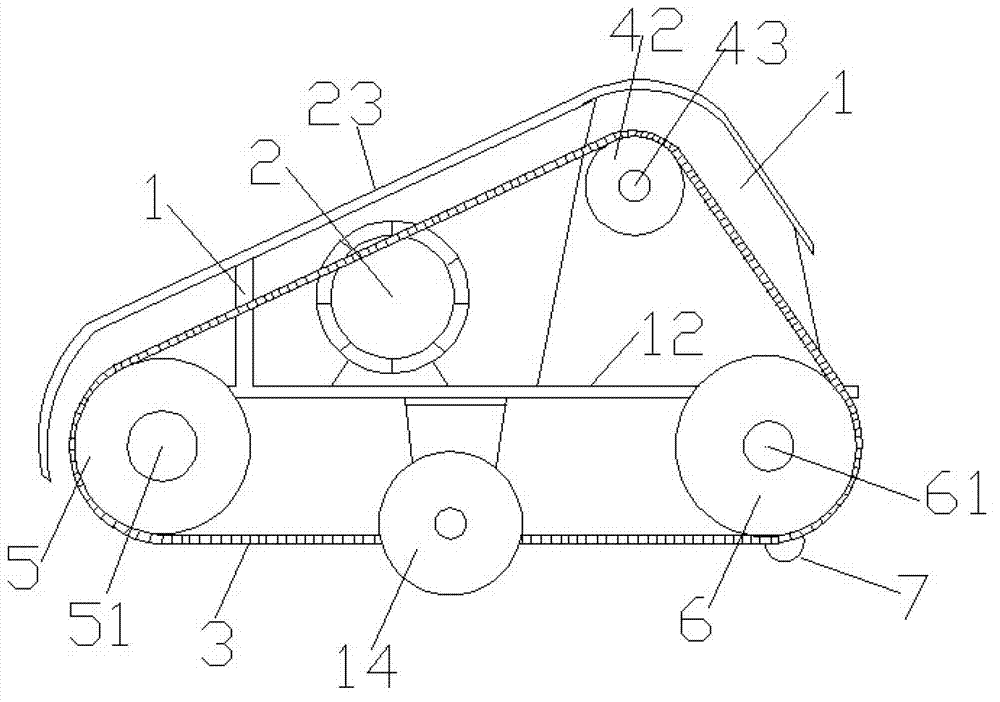

[0012] Attached below Figure 1 to Figure 3 , the present invention is further described:

[0013] A welding seam grinding vehicle for repairing composite panels, comprising a vehicle frame 1, the vehicle frame 1 comprising a frame rod 11 mounted on a bottom plate 12 of the frame and wheels 14 mounted on the bottom surface of the bottom plate 12 of the frame. A handle 13 is installed at the end of the frame bar 11, and a control panel is set on the frame bar 11 at the bottom of the handle; a wheel shaft one 51 and a wheel shaft two 61 are respectively arranged in parallel at the two ends of the frame bottom plate 12, Motor 2 is installed on the vehicle frame bottom plate between described wheel shaft one 51 and wheel shaft two 61, and motor wheel 21 is housed on the motor shaft of described motor 2, and one end corresponding to described wheel shaft one 51 and described motor wheel 21 is installed Driven wheel 4, the other end of described wheel shaft one 51 is installed work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com