Mechanical acceleration type locomotive tackifying and sanding device

A technology of sand spreading device and acceleration device, which is applied to locomotives and other directions, can solve the problems such as the inability to accurately adjust and control the amount of sand sprinkled, the aggravation of wheel-rail wear and the circuit insulation between the wheel and rail, and the low speed of sand particle injection, so as to avoid excessive sand particles. The effect of sanding, improving the efficiency of particle injection and avoiding airflow interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

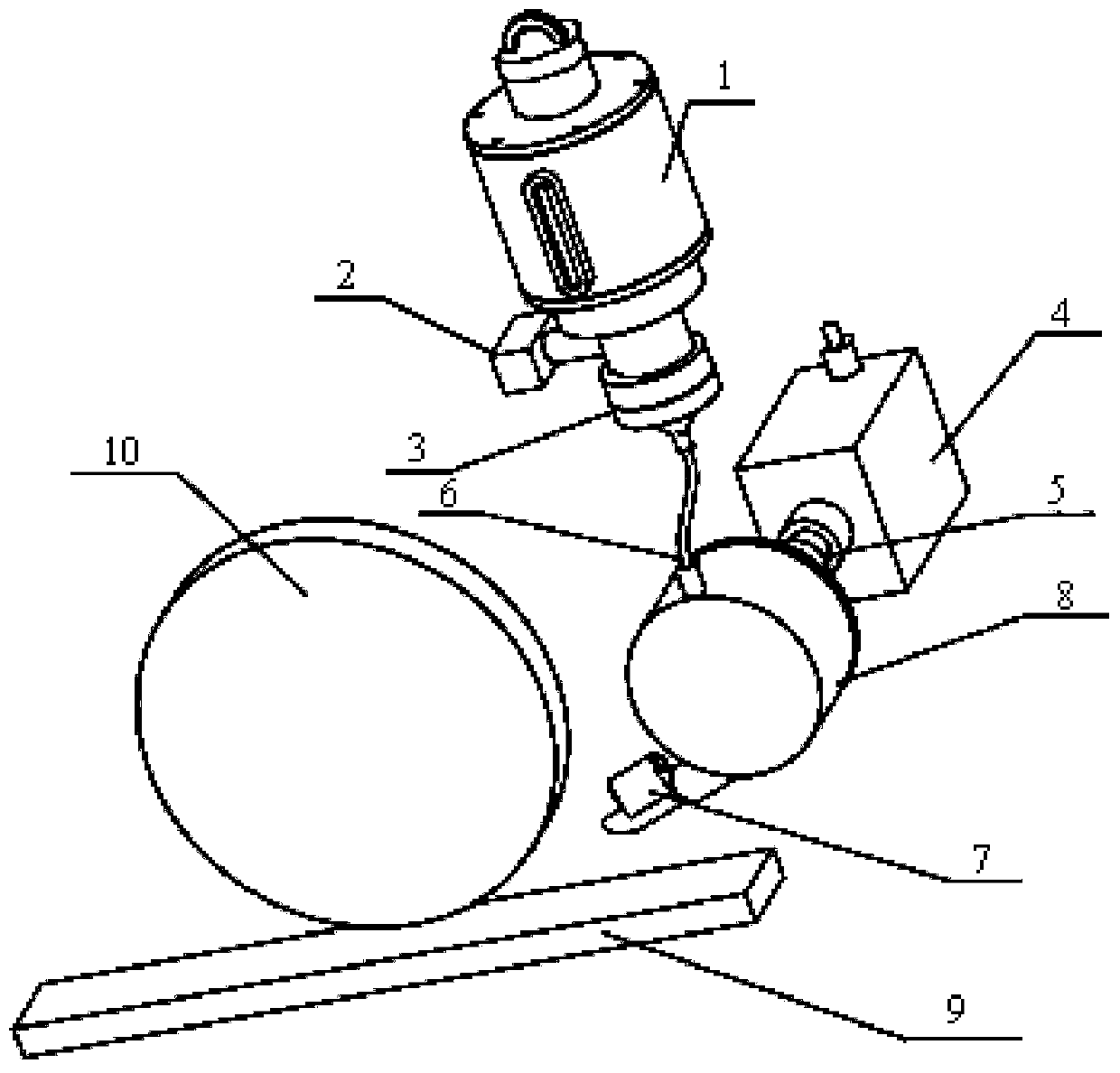

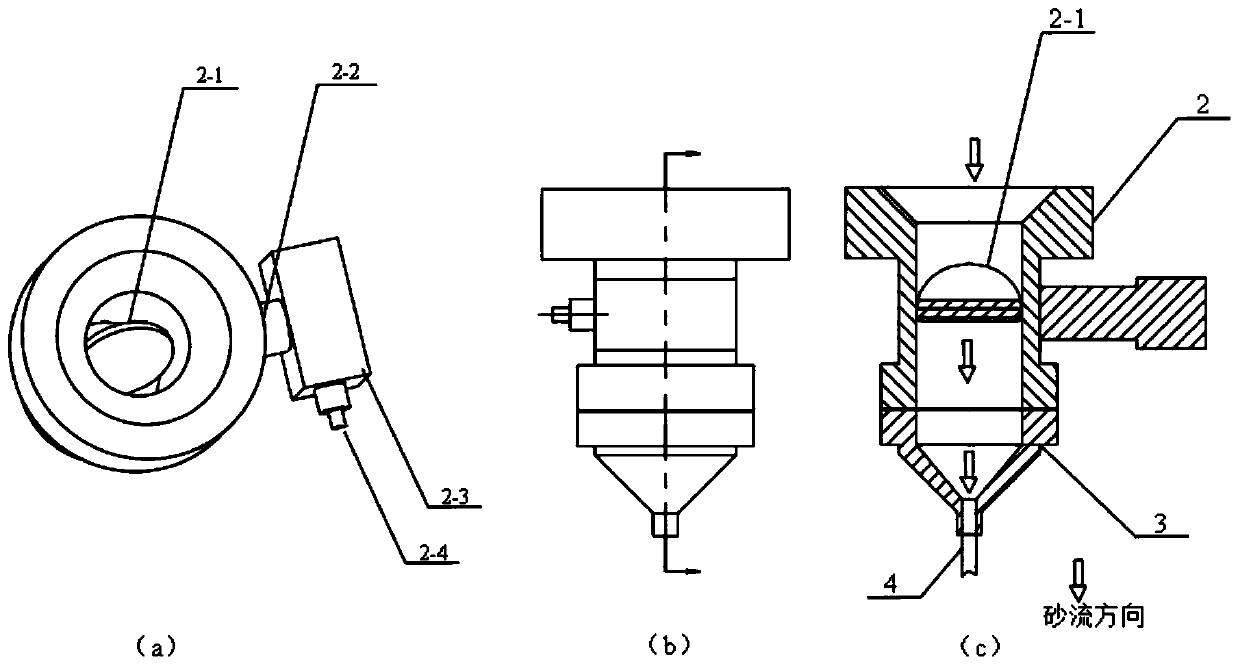

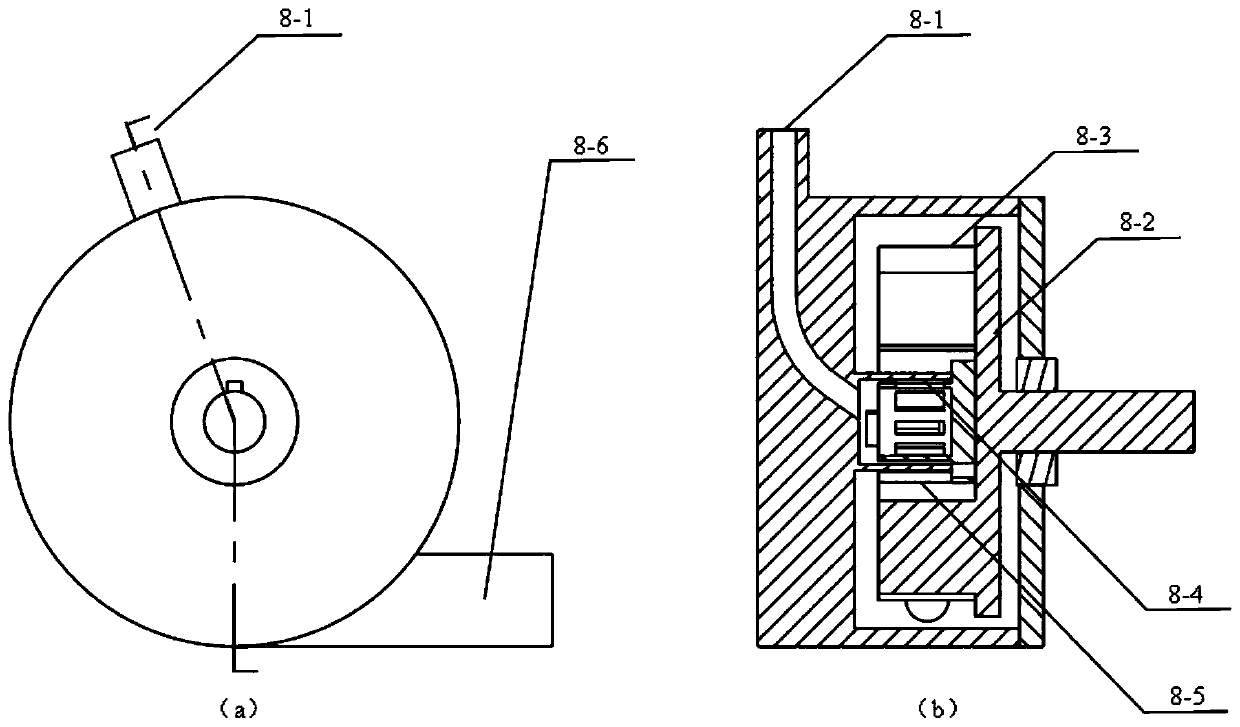

[0022] Such as Figure 1~4 As shown, a mechanically accelerated locomotive viscosity-increasing sand spreading device includes a sand box 1, and a flow control valve 2 is provided at the connection between the lower end of the sand box 1 and the funnel 3; it also includes an acceleration device 8 for accelerating sand particles. The lower end of the funnel 3 is connected to the sand inlet 8-1 of the acceleration device 8 through the flexible pipe 6; the acceleration device 8 includes the impeller 8-2 and the sub-grinding wheel 8-4 arranged at the center of the impeller 8-2; the sub-grinding wheel 8-4 outside Orientation sleeve 8-5 is provided; it also includes a plurality of blades 8-3 evenly arranged on the impeller 8-2. The orientation sleeve 8-5 is provided with a plurality of through holes, and the through holes correspond to the gap betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com