Steel rail composite grinding wagon

A technology for grinding cars and rails, which is applied to rails, laying rails, rail maintenance and other directions. It can solve the problems of large amount of rail grinding and grinding, wide grinding angle range, and good workability. The effect of large scope and good work passability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] as attached figure 1 to attach Figure 19 As shown, an embodiment of a rail composite grinding device 200 applied to a rail composite grinding vehicle 400 of the present invention specifically includes:

[0072] An enveloping grinding unit 1 and a profiling grinding unit 2 arranged above the rail 3 along the working direction;

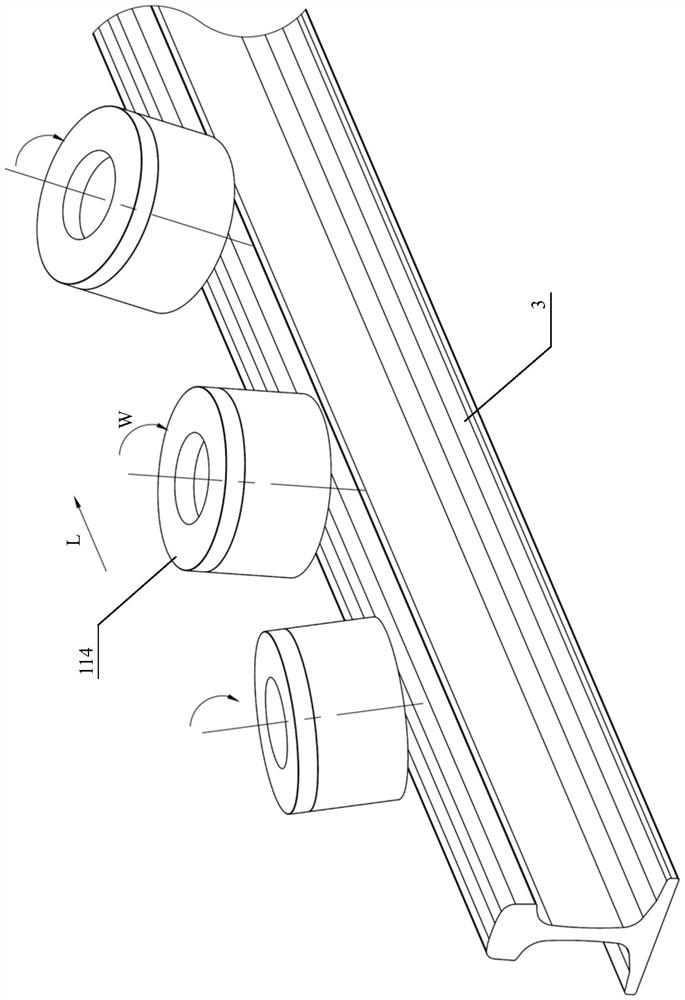

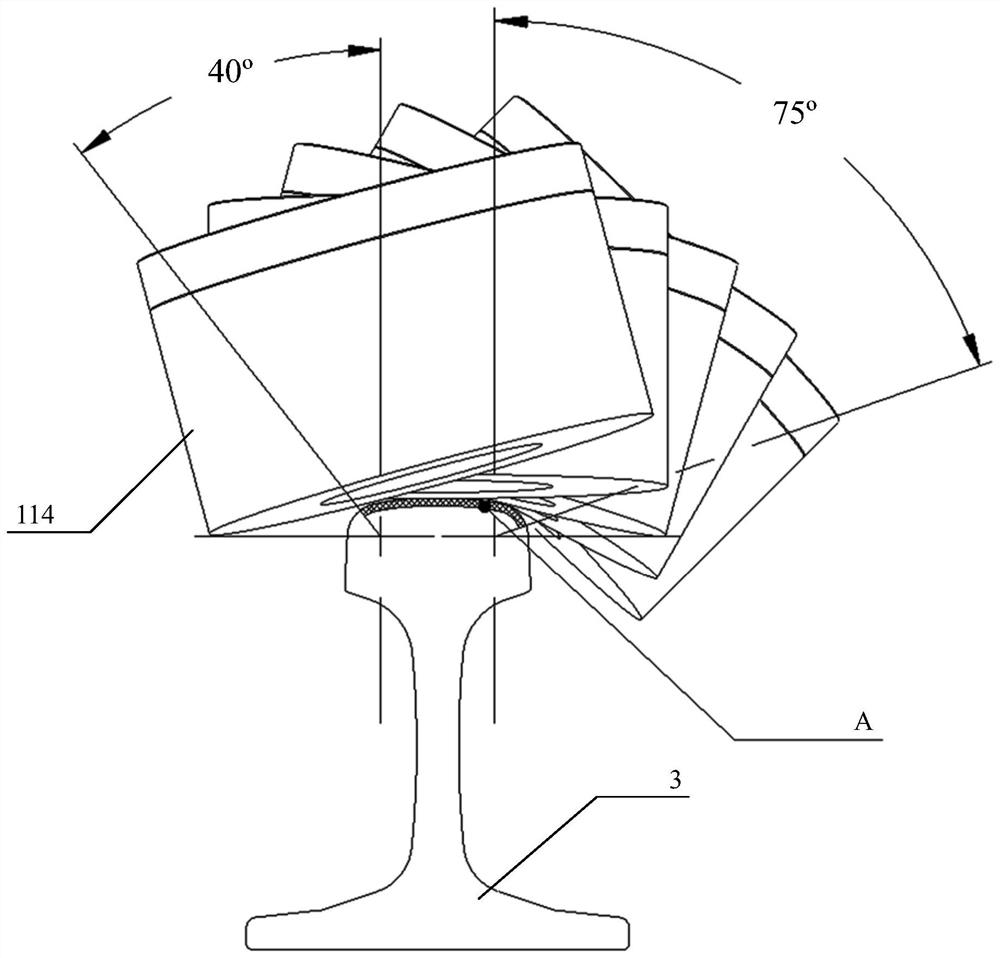

[0073] The enveloping grinding unit 1 utilizes the first grinding wheel 114 to carry out enveloping grinding on the rail surface of the rail 3, the first grinding wheel 114 adopts a cup-shaped grinding wheel, as attached figure 1 And attached figure 2 shown;

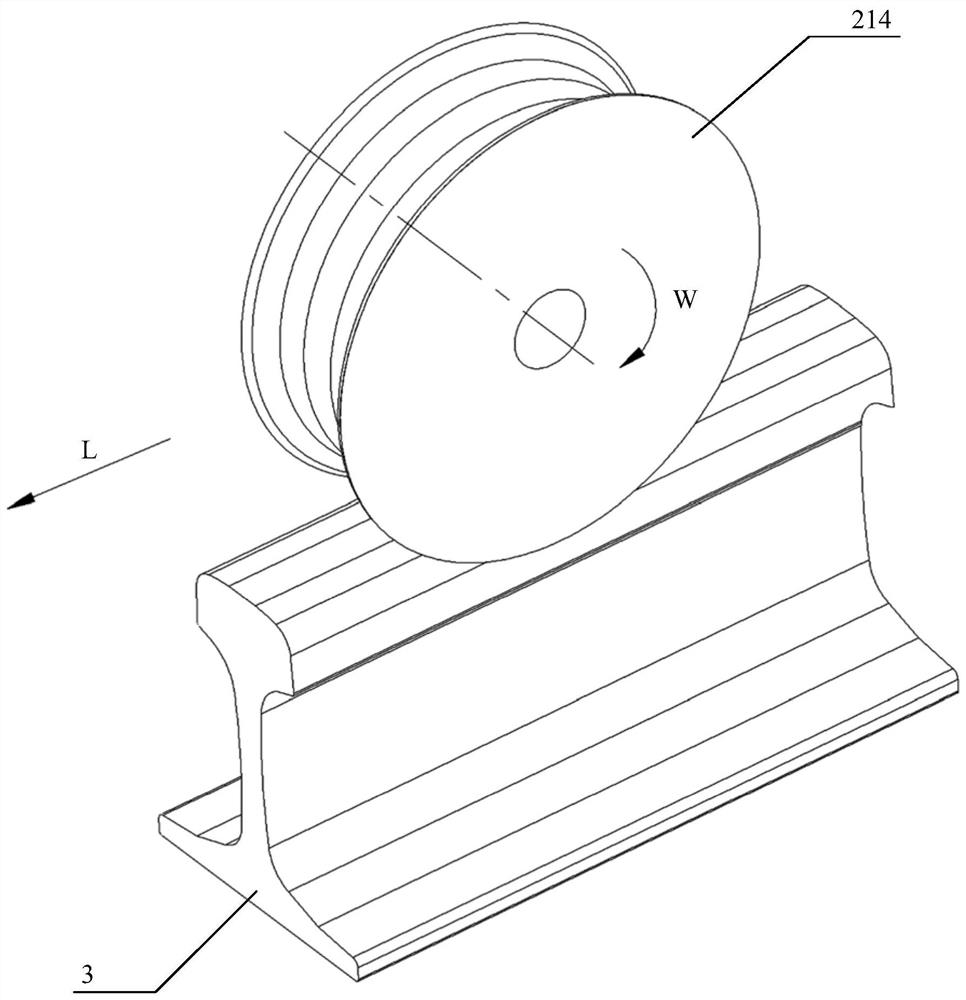

[0074]The profiling grinding unit 2 utilizes the second grinding wheel 214 to carry out profiling grinding on the rail surface of the rail 3, and the second grinding wheel 214 adopts a profiling grinding wheel, as attached image 3 And attached Figure 4 shown.

[0075] The grinding face of the second grinding wheel 214 is processed into all or part of the target profile of the rail...

Embodiment 2

[0084] as attached Figure 20 to attach Figure 24 Shown, a kind of embodiment of rail composite grinding vehicle 400 of the present invention, specifically comprises:

[0085] Body 600;

[0086] The vehicle frame 300 arranged at the lower part of the vehicle body 600;

[0087] And installed on the vehicle frame 300 , such as the compound rail grinding device 200 described in Embodiment 1, the compound rail grinding device 200 includes at least one rail grinding device 100 .

[0088] The rail compound grinding car 400 further includes:

[0089] One end is connected to the bottom of the rail compound grinding vehicle 400, and the other end is connected to the lifting mechanism 6 of the vehicle frame 300;

[0090] The traction mechanism 7 that is installed on the bottom of the rail compound grinding car 400 and connected with the vehicle frame 300;

[0091] As well as the fireproof and dustproof device 500 installed on the vehicle frame 300 and arranged outside the vehicle ...

Embodiment 3

[0102] as attached Figure 31 As shown, an embodiment of a rail composite grinding method based on the rail composite grinding vehicle 400 described in Embodiment 2 specifically includes the following steps:

[0103] S10) using the cup-shaped grinding wheel of the envelope grinding unit 1 to perform enveloping grinding on the rail surface of the rail 3;

[0104] S20) Use the profile grinding wheel of the profile grinding unit 2 to perform profile grinding on the rail surface of the rail 3 after envelope grinding.

[0105] In step S10), the envelope grinding unit 1 is adjusted to the set lateral position and inclination angle, and grinds the rail surface of the rail 3 through the end face of its cup-shaped grinding wheel, and the combination of 1 to 7 cup-shaped grinding wheels Realize the enveloping of the entire target profile of the 3 rail surfaces on one side of the rail.

[0106] In step S20), the profiling grinding unit 2 is adjusted to a set lateral position, and grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com