Opening closing and grinding structure for self-locking nut of aerospace vehicle

A self-locking nut, aerospace technology, applied in the aerospace field, can solve problems such as aerospace accidents, weakening of anti-loosening torque, loosening of connectors, etc., to achieve the effect of reducing cost, good anti-vibration ability, and avoiding excessive grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

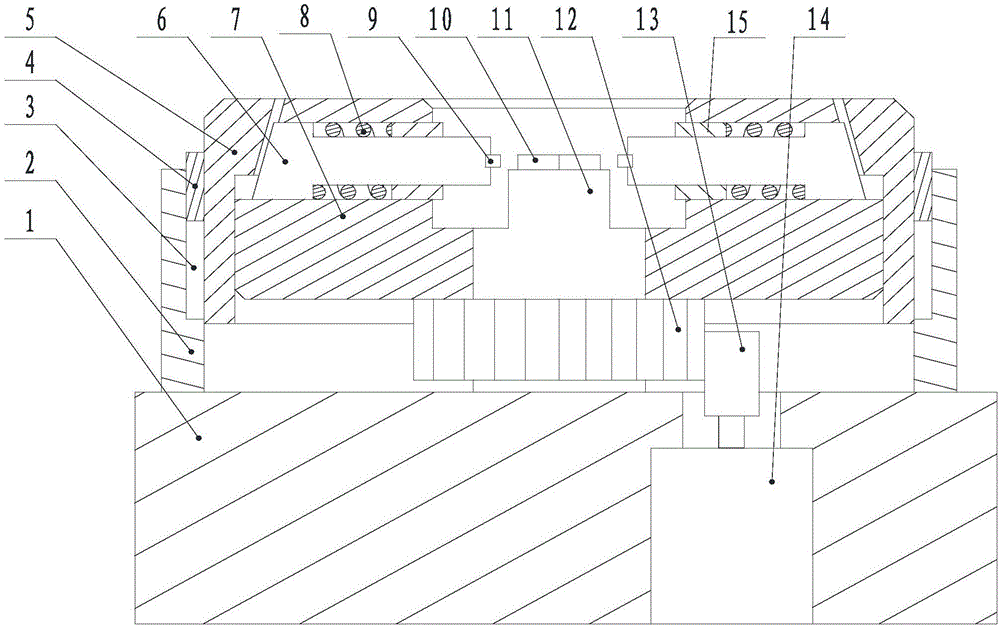

[0026] Such as figure 1 As shown, this embodiment includes a base 1 and a column 11 arranged on the base 1. A limit hole for matching with the self-locking nut 10 is opened on the upper end surface of the column 11, and an annular ring sleeved on the column 11 is also included. The closing plate 7 has a plurality of straight holes on its body along the radial direction of the closing plate 7, and the end of the top tightening block 6 moves through the straight holes and then extends to the middle of the closing plate 7, and at the end of the extension section of the top tightening block There is a grinding sheet 9 matching the closing part of the self-locking nut 10 on the upper part, and the grinding sheet 9 is facing the upper end of the limiting hole. In the prior art, the processing requirements for aerospace parts are relatively high. Except for the requirements of the material itself, the requirements for the processing technology of the parts are relatively strict. The...

Embodiment 2

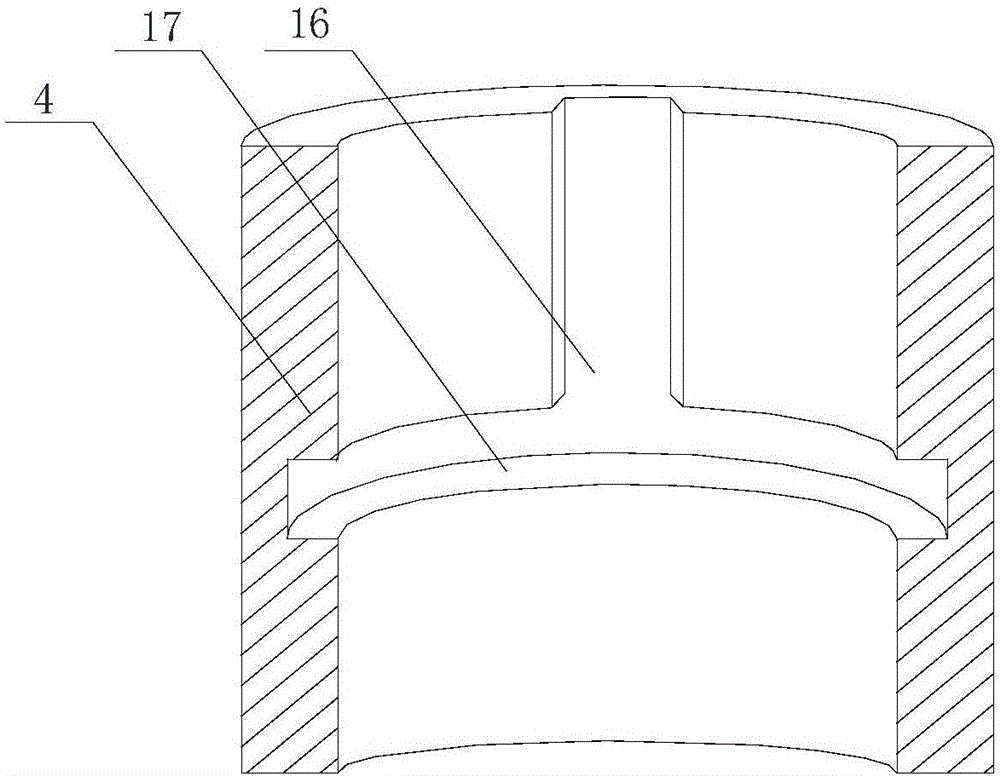

[0029] Such as figure 1 As shown, the clamping block 6 is T-shaped, a block 15 is provided at the end of the straight hole close to the column 11, and the horizontal section of the clamping block 6 moves through the block 15, and the grinding sheet 9 is arranged on the The end of the horizontal section of the tight block 6 and the two ends of the vertical section 16 of the tight block 6 contact with the inner wall of the straight hole respectively. The top tight block 6 adopts a T shape, and the end of one side of the horizontal section of the top tight block 6 is connected to the midpoint of its vertical section 16, and the end of the horizontal section of the top tight block 6 moves through the block 15, and the top tight block 6 The two ends of the vertical section 16 are respectively in contact with the inner wall of the straight hole. At this time, compared with when the top tightening block body completely penetrates the straight hole, the contact area between the top ti...

Embodiment 3

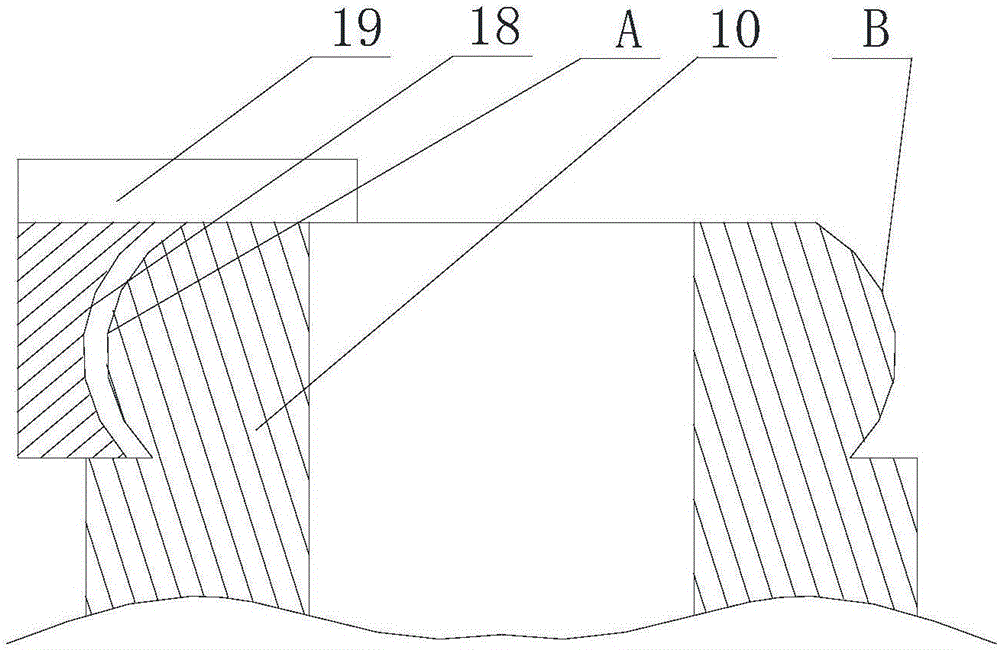

[0032] Such as figure 1 As shown, it also includes a top ring 5 coaxial with the closing plate 7, the lower section of the inner wall of the top ring 5 is threadedly matched with the outer peripheral wall of the closing plate 7, and a protrusion is provided on the upper section of the inner wall of the top ring 5, And the protruding part is in contact with the end of the tightening block 6, and the top ring 5 is rotated to force the protruding part to push the tightening block 6 to move toward the middle of the closing disc 7 along the radial direction of the closing disc 7. When the jacking block 6 is driven, the inventor abandons the synchronous drive of multiple cylinders or oil cylinders, and adopts a relatively stable driving method, that is, the outer circumference of the closing disc 7 is provided with a top ring 5 threaded with it. The upper section of the inner side wall of the tight cover is provided with a protrusion, and the protrusion cooperates with the outer sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com