Automobile engine fault detection device and detection method

A technology for automobile engine and fault detection, applied in the direction of internal combustion engine testing, etc., can solve the problems of high engine fault maintenance cost, affecting driving safety, and labor-consuming, etc., and achieving the effect of long labor-hours, high transmission rate, and high maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

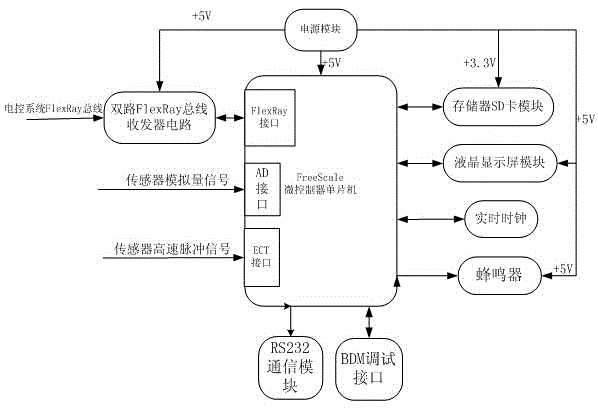

[0050] An automobile engine fault detection device, which includes a controller, a dual-channel FlexRay bus transceiver circuit connected to the controller through a FlexRay interface, an analog sensor unit connected to the controller through an AD interface, and a digital sensor unit connected to the controller through an ECT interface connect.

[0051] The dual-way FlexRay bus transceiver circuit is connected to the FlexRay bus of the electronic control system to receive information from the FlexRay bus of the electronic control system.

[0052] The AD interface mainly receives the sensor analog signal.

[0053] The ECT interface receives the high-speed pulse signal of the sensor.

[0054] The controller is also connected with the RS232 communication module, BDM debugging interface, memory SD card module, LCD display module, real-time clock and buzzer; the input terminal of the power module is connected with the vehicle battery, and the output terminal is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com