Disc device and semiconductor integrated circuit and pick-up control method and vibration component test method

A technology of optical disc device and pickup head, applied in recording/reproducing by optical method, arrangement/installation of head, recording of information on magnetic disc, etc., can solve the difficulty of vibration resistance, short focal distance, loss of servo control and other problems to achieve the effect of improving vibration detection performance and improving vibration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

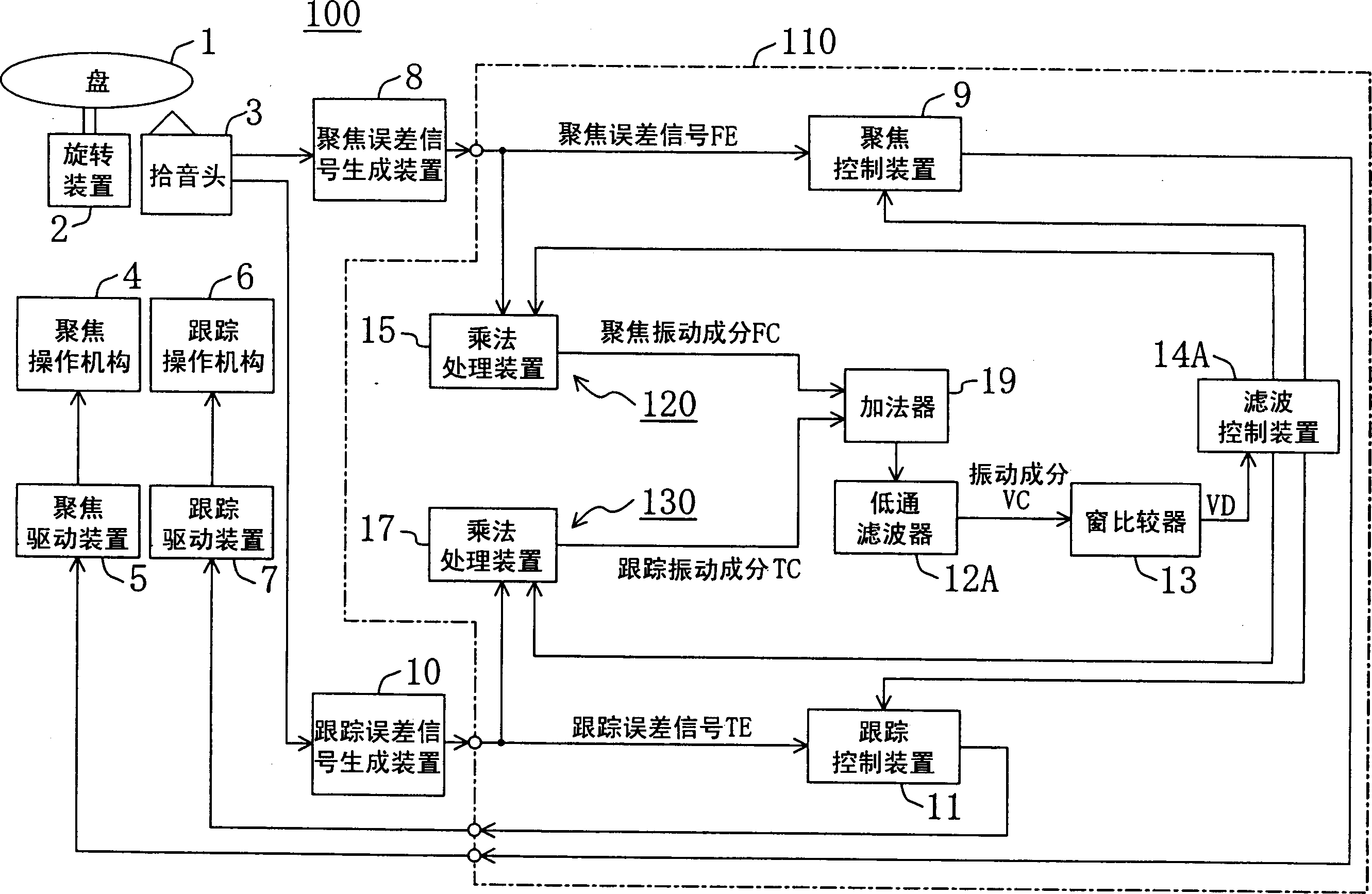

[0037] figure 1 The configuration of the optical disc device 100 according to Embodiment 1 of the present invention is shown. Next, the optical disc device 100 will be described in detail, but Figure 4 The components in the illustrated optical disc devices are the same, and the description thereof will be omitted by using the same reference numerals.

[0038] The optical disc device 100 includes: a focus component generator 120 that generates a focus vibration component FC from the focus error signal FE; a tracking component generator 130 that generates a tracking vibration component TC from the tracking error signal TE; Adder 19 for adding component TC; and low-pass filter 12A for extracting vibration component VC from the addition result of adder 19 (corresponding to the extracting means of the present invention). It performs focus control and tracking control of the pickup 3 according to the vibration component.

[0039] In addition, the focus component generation part ...

Embodiment 2

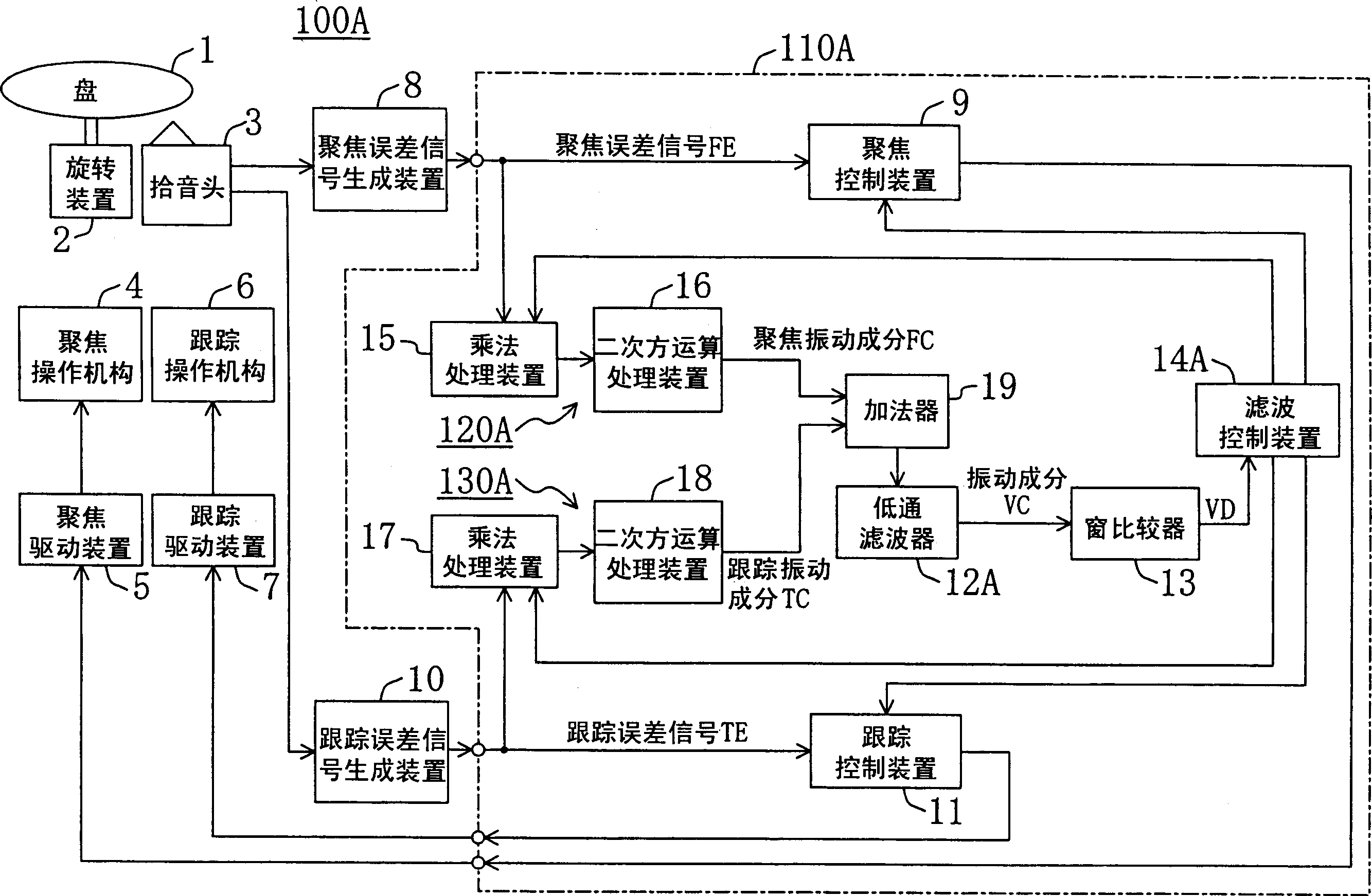

[0055] In the first embodiment described above, the multiplied focus error signal FE and tracking error signal TE are added as they are. However, when compound vibration occurs in the focus direction and the track direction, the phases of the focus error signal FE and the tracking error signal TE may be reversed, and the levels may be reversed. At this time, if the focus error signal FE and the tracking error signal TE are simply added together, the vibration components will be canceled out, so that accurate vibration detection may not be possible.

[0056] In the optical disc device according to the second embodiment of the present invention, even when the above-mentioned composite vibration occurs, accurate vibration components can be extracted and accurate vibration detection can be performed. figure 2 The configuration of an optical disc device 100A according to Embodiment 2 of the present invention is shown. Next, the optical disc device 100A according to Embodiment 2 o...

Embodiment 3

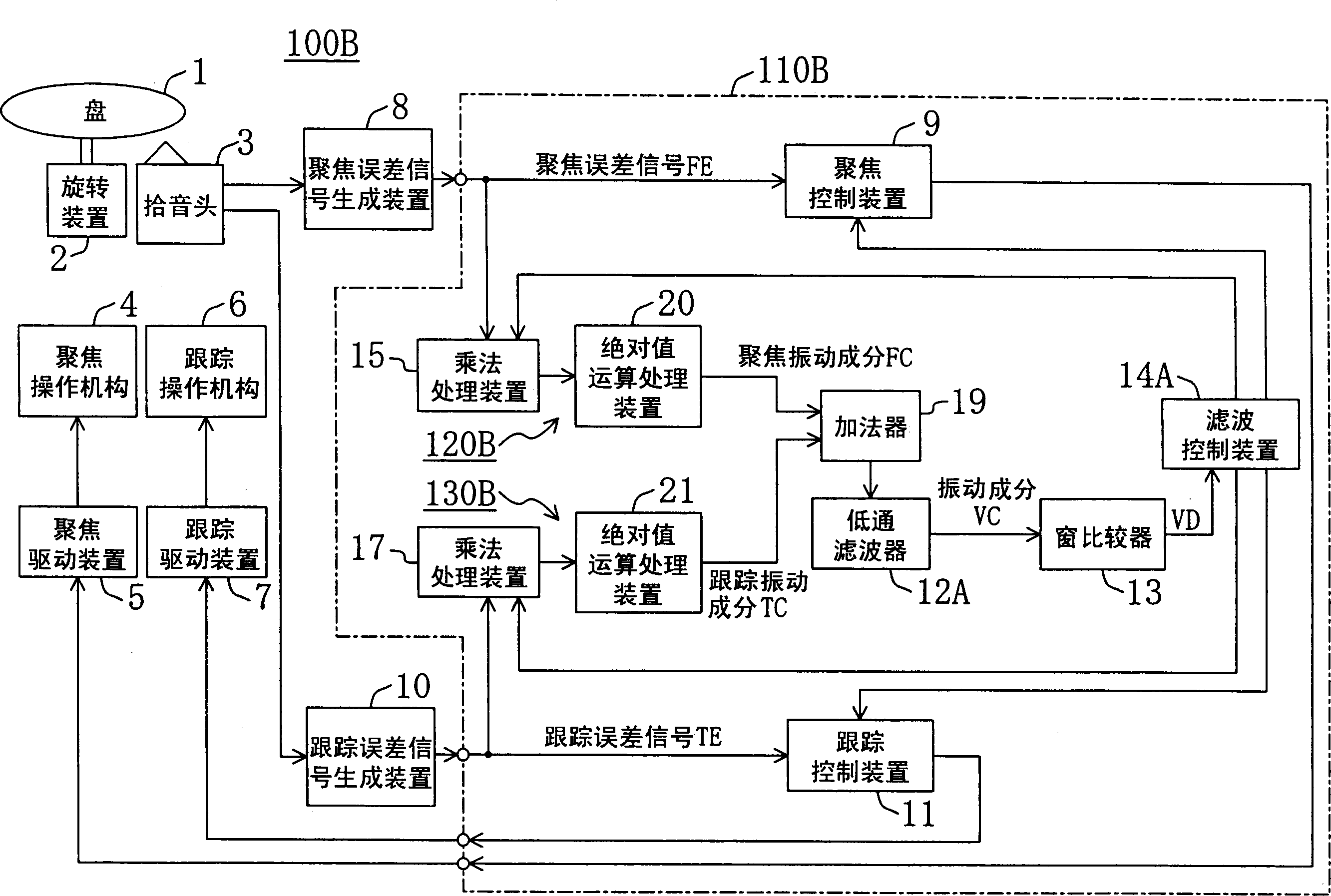

[0064] The optical disk device according to the third embodiment of the present invention is different from the second embodiment and responds to the case where compound vibration occurs.

[0065] image 3 The configuration of an optical disc device 100B according to Embodiment 3 of the present invention is shown. Next, the optical disc device 100B will be described in detail, but the figure 1 and Figure 4 The same components in the shown optical disc devices are denoted by the same symbols and their descriptions are omitted.

[0066] The focus component generation unit 120B in the optical disc device 100B is composed of the multiplication processing unit 15 and the absolute value calculation processing unit 20 . Similarly, the tracking component generation unit 130B is composed of the multiplication processing unit 17 and the absolute value calculation processing unit 21 . In addition, both the focus component generation unit 120B and the tracking component generation un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com