Method for establishing plane putty robot polishing database

A robot and database technology, applied in database design/maintenance, electrical digital data processing, structured data retrieval, etc., can solve the problems of unreproducible and repeated grinding work, unguaranteed grinding quality, low grinding efficiency, etc., to avoid The effect of excessive grinding, less variable parameters, and improved grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

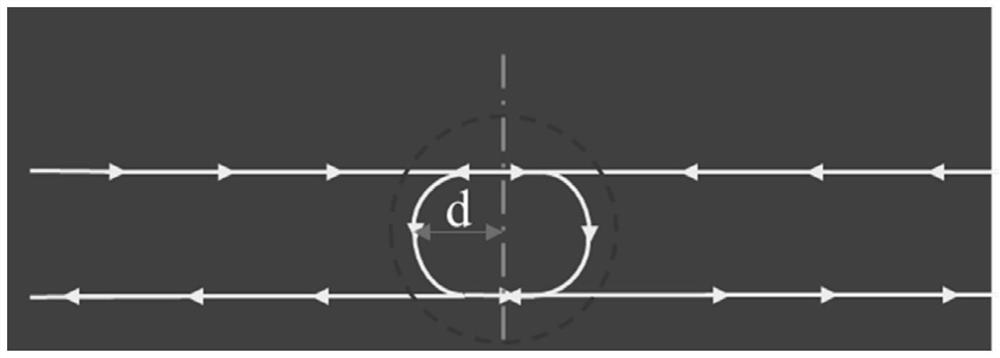

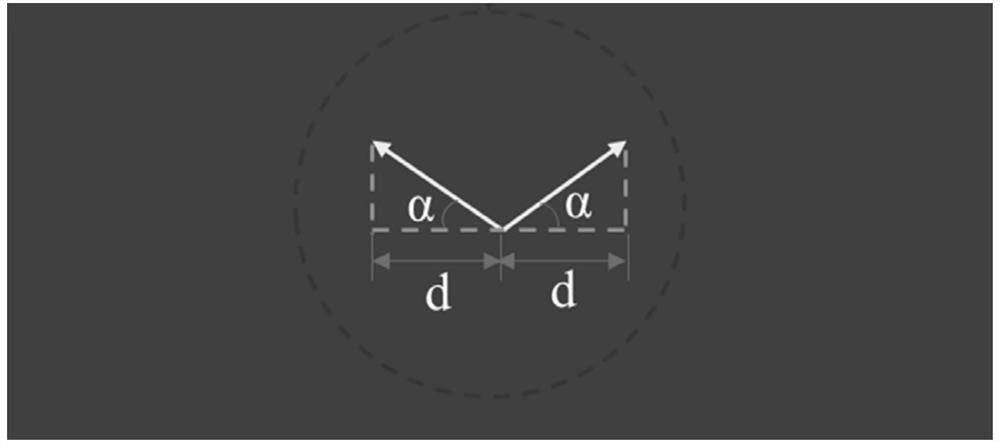

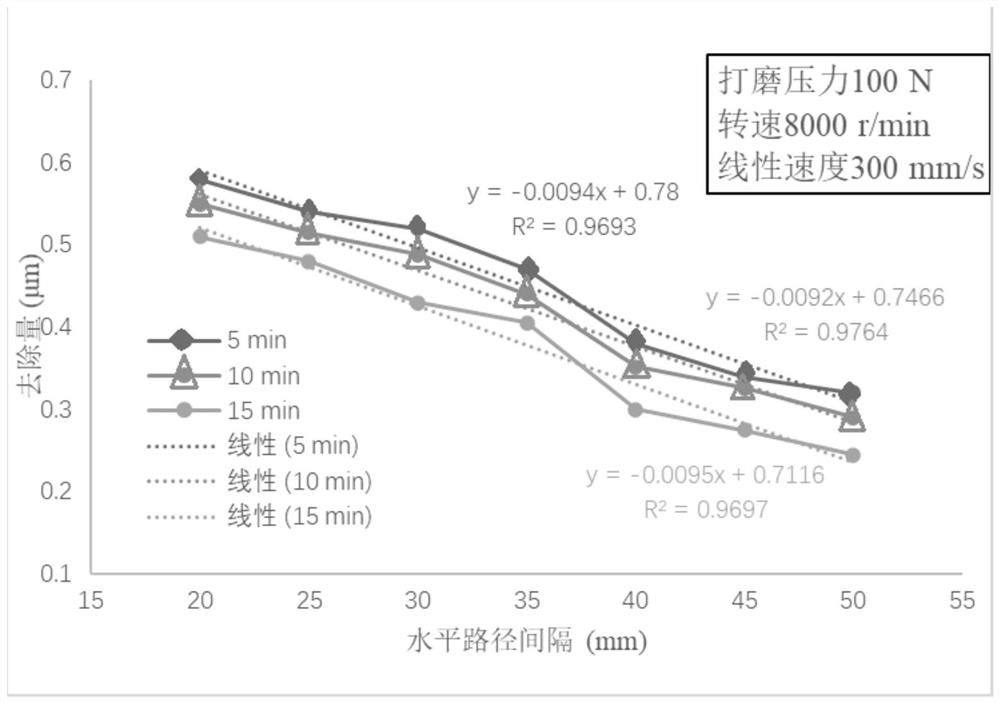

[0036] The invention provides a method for establishing a flat putty robot grinding database, which is suitable for a grinding robot device to perform putty grinding operations within a plane range, such as the plane grinding of putty on a large-area side wall of a high-speed rail car body, near a car door, and near a car window. The grinding robot device provided by the invention includes a robot grinding system, a robot control system, and a grinding control system, wherein the robot grinding system includes a robot and a grinding system installed at the end of a robot grinding arm (mechanical arm). In this embodiment, the grinding The system adopts the AOK grinding system. The AOK grinding system is an integrated grinding system, including a force control system and a grinding system, which can facilitate integrated control of grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com